Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Four-core 600/1000V Cables with Stranded Copper Conductors

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

CONSTRUCTION

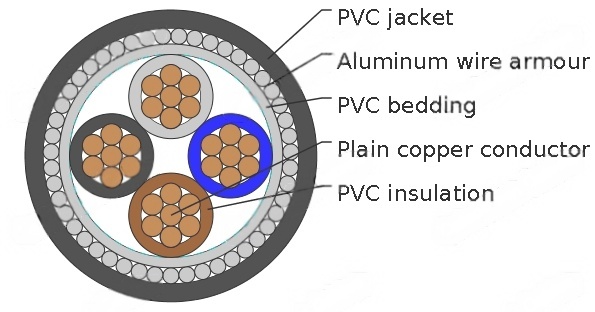

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Number/wire | Nominal insulation thickness | Nominal bedding thickness | Nominal wire armor dia. | Nominal sheath thickness | Approx. overall diameter | Approx.cable weight | |

|---|---|---|---|---|---|---|---|---|

extruded bedding | taped | |||||||

mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 13.5 | - | 330 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 15.0 | - | 430 | |

7/0.85 | 0.8 | 0.8 | 1.25 | 1.5 | 17.8 | - | 640 | |

7/1.04 | 0.8 | 0.8 | 1.25 | 1.5 | 19.2 | - | 770 | |

7/1.35 | 1.0 | 0.8 | 1.25 | 1.6 | 22.8 | - | 1070 | |

7/1.70 | 1.0 | 1.0 | 1.6 | 1.7 | 26.3 | 25.9 | 1550 | |

7/2.14 | 1.2 | 1.0 | 1.6 | 1.8 | 30.7 | 30.3 | 2005 | |

7/2.14 | 1.2 | 1.0 | 1.6 | 1.8 | 27.8 | 27.4 | 2005 | |

19/1.53 | 1.2 | 1.0 | 1.6 | 1.9 | 33.7 | 33.3 | 2490 | |

19/1.53 | 1.2 | 1.0 | 1.6 | 1.9 | 30.3 | 29.9 | 2490 | |

19/1.78 | 1.4 | 1.2 | 2.0 | 2.0 | 35.4 | 34.6 | 3475 | |

19/2.14 | 1.4 | 1.2 | 2.0 | 2.1 | 39.2 | 38.4 | 4480 | |

19/2.52 | 1.6 | 1.2 | 2.0 | 2.2 | 43.3 | 43.5 | 5710 | |

37/2.03 | 1.6 | 1.4 | 2.5 | 2.4 | 49.3 | 48.1 | 7350 | |

37/2.25 | 1.8 | 1.4 | 2.5 | 2.5 | 53.6 | 52.4 | 8720 | |

37/2.52 | 2.0 | 1.6 | 2.5 | 2.6 | 59.0 | 57.4 | 10540 | |

61/2.25 | 2.2 | 1.6 | 2.5 | 2.8 | 65.7 | 64.1 | 13290 | |

61/2.52 | 2.4 | 1.6 | 2.5 | 3.0 | 72.0 | 70.4 | 16050 | |

61/2.85 | 2.6 | 1.8 | 3.15 | 3.3 | 81.3 | 79.3 | 20950 | |

*Shaped stranded conductor (class 2)

Introduction

In the realm of electrical engineering, the choice of power cables can make or break the efficiency and safety of an industrial installation. But why are four-core 600/1000V cables with stranded copper conductors particularly suited for demanding environments like refineries and chemical plants? These cables, designed for low-voltage electricity supply, offer a blend of robustness, flexibility, and reliability that addresses the unique challenges of underground and industrial use. This article provides an in-depth analysis based on standard specifications, drawing from technical data on their construction, performance, and common pitfalls.

Four-core cables typically consist of four insulated conductors bundled together, often used for three-phase power systems with a neutral or for control purposes. The 600/1000V rating indicates they are optimised for systems where the voltage to earth is up to 600V and between conductors up to 1000V, making them ideal for low-voltage installations. Stranded copper conductors, as opposed to solid ones, enhance flexibility and durability, crucial in settings where cables may be subjected to bending, vibration, or mechanical stress.

These cables are engineered to withstand chemical exposure and physical abuse, ensuring uninterrupted power supply in harsh conditions. According to industry standards like IEC 60228 for conductors and IEC 60332 for flame retardancy, they incorporate materials such as polyvinyl chloride (PVC) for insulation and steel wire armour (SWA) for protection. This design not only meets safety requirements but also extends service life, reducing downtime in critical operations.

In South Africa, where industrial sectors like mining and petrochemicals rely heavily on reliable electricity distribution, these cables align with local regulations under the South African National Standards (SANS). By examining their construction, technical parameters, advantages of stranded copper, and common issues, this article aims to equip engineers and technicians with the knowledge to select, install, and maintain these vital components effectively.

Applications in Industrial Settings

Four-core 600/1000V cables with stranded copper conductors find extensive use in low-voltage installation systems, particularly where underground deployment is necessary. Their adaptability to industrial applications stems from their ability to provide stable electricity supply while resisting environmental hazards. In refinery areas and chemical plants, for instance, these cables are employed to connect motors, pumps, and control systems, ensuring seamless operation amidst corrosive substances and mechanical risks.

The four-core configuration is especially beneficial for balanced three-phase power distribution, with the fourth core often serving as a neutral or earth conductor. This setup minimises voltage imbalances and enhances system efficiency. In underground installations, common in South African mines, the cables' armouring protects against soil pressure, rodent damage, and accidental excavation. Their voltage rating of 600/1000V suits applications up to 1kV, covering a wide range of equipment from lighting circuits to heavy machinery.

Beyond petrochemicals, these cables are utilised in manufacturing plants for conveyor systems and in wastewater treatment facilities for pump controls. Their flame-retardant properties, compliant with IEC 60332 Part 1, prevent fire propagation, a critical feature in confined spaces. Moreover, the PVC outer sheath offers resistance to oils and chemicals, making them suitable for areas with potential spills.

In renewable energy setups, such as solar farms in arid regions, these cables connect inverters to the grid, handling intermittent loads without degradation. The stranded copper design allows for easier routing through conduits, reducing installation time and costs. Overall, their versatility positions them as a cornerstone for safe and efficient power transmission in diverse industrial landscapes.

In-Depth Analysis of Stranded Copper Conductors

Stranded copper conductors are a hallmark of these cables, offering distinct advantages over solid alternatives. Composed of multiple thin wires twisted together, they provide superior flexibility, essential for installations involving curves or vibrations. According to engineering analyses, stranded wires can endure millions of flex cycles without fatigue failure, unlike solid wires which may crack under repeated bending.

Copper's inherent properties amplify these benefits. With a conductivity 1.7 times that of aluminium, it minimises resistive losses, leading to energy efficiency. In power cables, this translates to lower heat generation, extending insulation life. Stranding also mitigates the skin effect in AC currents, where charge flows on the surface; more strands increase effective surface area, reducing AC resistance by up to 20% compared to solid cores.

In industrial contexts, the malleability of stranded copper allows for easier termination and splicing, reducing labour costs. Research from sources like Fluke Networks highlights that stranded cables resist metal fatigue, making them ideal for dynamic environments such as conveyor belts or robotic arms.

However, stranded conductors have higher manufacturing costs due to the twisting process, but this is offset by longevity. In comparison to solid copper, stranded versions exhibit lower DC resistance per unit length for the same cross-section, as the packing factor allows tighter bundles.

For four-core setups, stranded copper ensures even current distribution, preventing hotspots. Their use in 600/1000V cables aligns with IEC standards, where Class 2 stranding balances flexibility and compactness.

Armour and Protection Mechanisms

The SWA armour is pivotal for safeguarding these cables in hostile environments. Comprising galvanised steel wires helically wound around the bedding, it provides tensile strength exceeding 100kN for larger sizes and crush resistance up to 5kN/cm. This protects against mechanical damage during installation or operation, such as from digging tools or vehicle loads.

In underground applications, the armour also deters rodent attacks and absorbs soil movements. The outer PVC sheath complements this by offering chemical resistance, with a pH tolerance from 4 to 10, suitable for acidic or alkaline soils common in South African industrial sites.

Wikipedia notes that armour in low-voltage cables like these is earthed but not current-carrying, preventing induced voltages. For four-core designs, SWA ensures symmetry, maintaining electromagnetic compatibility.

Four-core 600/1000V cables with stranded copper conductors stand out for their resilience and efficiency in industrial power supply. By understanding their construction, advantages, and common issues, stakeholders can optimise their use, ensuring safe and reliable operations. As technology evolves, these cables remain a foundational element in electrical infrastructure.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430