Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Four-core 600/1000V cables with stranded copper conductors

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

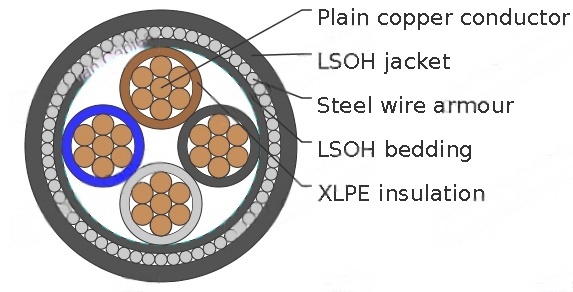

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal Bedding Thickness | Nominal Steel Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.7 | 0.8 | 0.9 | 1.4 | 13.3 | 390 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 15.0 | 470 | |

7/0.85 | 0.7 | 0.8 | 0.9 | 1.4 | 16.4 | 580 | |

7/1.04 | 0.7 | 0.8 | 1.25 | 1.5 | 18.7 | 805 | |

7/1.35 | 0.7 | 0.8 | 1.25 | 1.5 | 21.1 | 1090 | |

7/1.70 | 0.7 | 0.8 | 1.25 | 1.6 | 23.4 | 1320 | |

7/2.14 | 0.9 | 1 | 1.6 | 1.7 | 28.9 | 1840 | |

7/2.14 | 0.9 | 1 | 1.6 | 1.7 | 26.1 | 1840 | |

7/2.52 | 0.9 | 1 | 1.6 | 1.8 | 31.9 | 2310 | |

7/2.52 | 0.9 | 1 | 1.6 | 1.8 | 28.6 | 2310 | |

19/1.78 | 1.0 | 1 | 1.6 | 1.9 | 32.0 | 2970 | |

19/2.14 | 1.1 | 1.2 | 2.0 | 2.1 | 37.7 | 4240 | |

19/2.52 | 1.1 | 1.2 | 2.0 | 2.2 | 41.7 | 5400 | |

37/2.03 | 1.2 | 1.4 | 2.5 | 2.3 | 47.1 | 7000 | |

37/2.25 | 1.4 | 1.4 | 2.5 | 2.4 | 51.4 | 8350 | |

37/2.52 | 1.6 | 1.4 | 2.5 | 2.6 | 56.6 | 10130 | |

61/2.25 | 1.7 | 1.6 | 2.5 | 2.7 | 63.0 | 12840 | |

61/2.52 | 1.8 | 1.6 | 2.5 | 2.9 | 68.8 | 15530 | |

61/2.85 | 2 | 1.8 | 3.15 | 3.2 | 78.1 | 19950 |

In the realm of electrical engineering, the choice of cabling can make or break the reliability and safety of an installation. Why, then, are four-core 600/1000V armoured cables with stranded copper conductors increasingly favoured in South Africa? These cables, designed for power and control circuits, offer robust protection against mechanical stress, environmental hazards, and fire risks, making them ideal for diverse applications from industrial sites to residential buildings.

Applications: Versatility in Power and Control Circuits

These cables find extensive use in power distribution and control applications, both indoors and outdoors. Their SWA armour allows for direct burial in trenches, ideal for connecting substations to buildings or powering remote equipment in rural areas. In South Africa, where infrastructure projects span vast terrains, these cables are pivotal in mining operations, agricultural setups, and urban developments.

For instance, in control circuits, the four cores can handle three-phase power plus neutral, supporting motors, lighting, and automation systems. Their voltage rating of 600/1000V suits low-voltage networks, common in commercial and industrial installations. The ability to withstand temperatures from 0°C to +90°C makes them suitable for the country's varied climate, from the cold Highveld winters to scorching Kalahari summers.

Installation practices, such as laying in underground trenches with caution tape, further enhance safety: According to SANS 10142-1, cables must be protected from mechanical damage, and SWA provides this inherently, reducing the need for additional conduits in many cases.

Benefits: Protection, Safety, and Longevity

The primary advantage is mechanical protection from the SWA, guarding against excavation damage or vehicular impact—crucial in construction-heavy South Africa. XLPE insulation resists chemical corrosion and UV degradation, extending service life.

In fire scenarios, LSOH sheaths minimise smoke and halogens, protecting lives and equipment in confined spaces. Energy efficiency stems from low-resistance copper conductors, reducing losses in long runs. Compared to unarmoured cables, these offer superior durability, with reduced maintenance costs over time.

In-Depth Analysis: Performance in South African Contexts

South Africa's diverse landscapes—from arid deserts to subtropical coasts—test cable resilience. In mining, where vibrations and abrasives abound, stranded copper and SWA ensure uninterrupted power to drills and pumps. Urban expansions in Johannesburg demand cables that handle high loads without overheating, leveraging XLPE's thermal properties.

Comparatively, aluminium conductors (also mentioned in specs) are lighter but less conductive; copper's superiority in efficiency justifies its use in critical circuits. Economic analysis shows that while initial costs are higher, reduced failures offset expenses, aligning with sustainable development goals.

Regulatory compliance is key; SANS 1507-3 mirrors BS 5467 for armoured cables, ensuring interoperability with imported equipment. Future trends may include enhanced eco-friendly materials, but current designs meet evolving needs.

Four-core 600/1000V armoured cables with stranded copper conductors stand out for their blend of flexibility, protection, and safety, addressing South Africa's unique electrical challenges. By mitigating common issues through superior materials and standards compliance, they ensure reliable power delivery. As infrastructure grows, these cables will remain indispensable, answering the question of their essentiality with proven performance and innovation.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430