Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

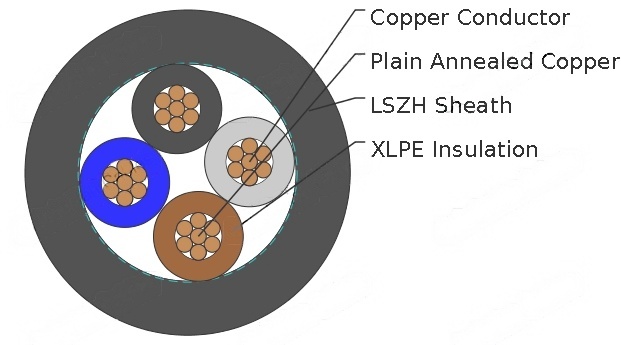

Four-core 600/1000V XLPE Insulation, LSZH Sheath Cables to BS 8573

Application

These XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts.

Standard

Basic design to BS 8573:2012

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2:2004 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | BS EN 60332-3-24:2009 (cat. C) |

Halogen Free | BS EN 50267-2-1 |

Minimum Smoke Emission | BS EN 61034-2 |

Spark Test | BS EN 62230 |

Voltage Rating

600/1000V

Construction

Conductor : Annealed copper conductor, strand according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2, or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Inner Covering option : The laid up cores may be coverd by an optional extrued inner covering or separating tape. It shall be possible to separate the cores easily.

Outer Sheath : Thermoplastic LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath option : UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option.

Color Code

Insulation Colour : Blue, brown black and grey; Alternatively, green-and-yellow, brown, black, grey

Sheath Colour : Black, other colours can be offered upon request.

Physical And Thermal Properties

Maximum temperature range during operation (XLPE) : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius:

Circular copper conductors(up to 25mm²) : 4 x Overall Diameter

Circular copper conductors(above 25mm²) : 6 x Overall Diameter

Shaped copper conductors : 8 x Overall Diameter

Construction Parameters

Conductor | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal Sheath Thickness | |

|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | |||

No. x mm² |

| mm | mm | mm |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 0.9 | 1.0 | 1.8 | |

2 | 1.0 | 1.0 | 1.8 | |

2 | 1.1 | 1.2 | 2.0 | |

2 | 1.1 | 1.2 | 2.1 | |

2 | 1.2 | 1.2 | 2.3 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 0.9 | 0.8 | 1.8 | |

2 | 1.0 | 1.0 | 1.8 | |

2 | 1.1 | 1.2 | 2.0 | |

2 | 1.1 | 1.2 | 2.1 | |

2 | 1.2 | 1.2 | 2.3 | |

Fire Performance and Safety:

One of the most compelling aspects of these cables is their exceptional fire performance, a critical factor in densely occupied structures. The LSZH sheath minimises smoke and fume emissions, addressing the primary cause of fatalities in fires—inhalation of toxic gases rather than flames themselves.

Flame retardance is tested to BS EN 60332-1-2, where a single cable withstands a vertical flame without excessive propagation. For bundled installations, BS EN 60332-3-24 (Cat. C) confirms reduced fire spread, vital in cable trays or conduits. Halogen-free compliance per BS EN 50267-2-1 limits hydrochloric acid release, preventing corrosion of nearby electronics and structural elements.

Smoke emission tests under BS EN 61034-2 ensure visibility during evacuation, a feature that has proven lifesaving in incidents like the Grenfell Tower fire, where smoke obscured escape routes. In South African contexts, such as high-rise buildings in Johannesburg or Cape Town, these properties align with fire safety bylaws, reducing the risk of mass casualties.

Analysing from a safety engineering perspective, the absence of halogens means no formation of dioxins or furans, toxic byproducts that exacerbate health issues. Compared to halogenated alternatives, LSZH cables offer a safer profile in hospitals, schools, and public transport hubs, where vulnerable populations are present. The spark test further assures no manufacturing defects that could ignite under load.

Thermally, the cables operate up to 90°C continuously and withstand 250°C for short circuits (5 seconds), preventing meltdown in overload scenarios. This resilience is crucial in variable climates like South Africa's, where ambient temperatures can fluctuate.

Applications and Installation:

Primarily for fixed building wiring, these cables excel in areas requiring low smoke emissions, such as tunnels, airports, and data centres. Not recommended for direct burial, they suit indoor conduits or trays, aligning with South African wiring regulations.

Installation benefits from the easy-separable cores and colour coding, speeding up terminations. In commercial projects, like shopping centres in Durban, they integrate seamlessly with fire alarm systems, enhancing overall safety.

From an environmental perspective, the halogen-free design supports green building certifications like Green Star SA, promoting sustainability. Economically, while initial costs may be higher than PVC cables, long-term savings from reduced fire damage and corrosion justify the investment.

Comparatively, against armoured variants, these unarmoured LSZH cables are lighter and more cost-effective for non-exposed runs, offering a balanced choice for modern infrastructures.

Advantages, Challenges, and Future Perspectives

Advantages include superior safety, durability, and compliance, making them indispensable in high-risk settings. Challenges involve higher upfront costs and the need for specialised handling to avoid insulation damage.

Looking ahead, advancements in material science may integrate smart monitoring into LSZH cables, aligning with South Africa's push towards smart cities. Globally, as regulations tighten on emissions, BS 8573-compliant cables will likely become the norm.

FAQs

What is XLPE insulation and why is it used in these cables? XLPE, or cross-linked polyethylene, is a thermoset material that provides excellent thermal and chemical resistance. It's used for its ability to handle higher temperatures (up to 90°C) and maintain insulation integrity, making it ideal for reliable power transmission.

How do LSZH sheaths differ from traditional PVC sheaths? LSZH sheaths are low smoke zero halogen, emitting minimal toxic fumes and smoke during fires, unlike PVC which releases halogens like chlorine, causing corrosion and health hazards.

Are these cables suitable for outdoor use in South Africa? While primarily for indoor fixed installations, options for UV and weather resistance can make them viable for protected outdoor applications, but not direct burial.

What fire tests do these cables comply with? They meet BS EN 60332-1-2 for single flame retardance, BS EN 60332-3-24 for bundled propagation, BS EN 50267-2-1 for halogen-free, and BS EN 61034-2 for low smoke.

Can custom colours be requested for the sheath? Yes, while black is standard, other colours can be provided upon request to suit specific identification needs.

What is the voltage rating and why is it 600/1000V? The rating indicates 600V phase-to-earth and 1000V phase-to-phase, standard for low-voltage building wiring to ensure safe operation under normal conditions.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430