Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H05V-R/H07V-R

Application and Description

These cables are preferably for installation indoors, in cable ducts and in industrial plants or switching stations, under ground installation. Can be used in switchboards and distributor boards or where a thicker strand of multi-wire is required. Found in electronic and electrical equipment and switchgear cabinets designed for export to a European country and for MRO replacement of European made equipment wire.

Standard and Approval

HD 21.3 S3

BS 6004

VDE-0281 Part-3

CEI 20-20/3

CEI 20-35 (EN60332-1)

CEI 20-52

CE Low Voltage Directive 73/23/EEC and 93/68/EEC

ROHS compliant

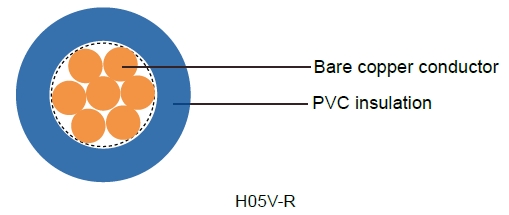

Cable Construction

Bare copper solid/strands conductor |

Strands to VDE-0295 Class-2, IEC 60228 Cl-2 |

Special PVC TI1 core insulation |

Cores to VDE-0293 colors on chart |

Technical Characteristics

WORKING VOLTAGE | 300/500 volts(H05V-R), 450/750 volts(H07V-R) |

|---|---|

TEST VOLTAGE | 2000 volts(H05V-R), 2500 volts(H07V-R) |

FLEXING BENDING RADIUS | 15 x Ø |

STATIC BENDING RADIUS | 15 x Ø |

FLEXING TEMPERATURE | -5 ºC to +70 ºC |

STATIC TEMPERATURE | -30 ºC to +80 ºC |

SHORT CIRCUIT TEMPERATURE | +160 ºC |

FLAME RETARDANT | IEC 60332.1 |

INSULATION RESISTANCE | 10 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA | NOMINAL THICKNESS OF INSULATION | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT | NOMINAL WEIGHT |

|---|---|---|---|---|---|

# X MM² | MM | MM | KG/KM | KG/KM | |

H05V-R | |||||

20(7/29) | 0.6 | 2.2 | 4.8 | 9 | |

18(7/27) | 0.6 | 2.4 | 7.2 | 12 | |

17(7/26) | 0.6 | 2.6 | 9.6 | 15 | |

H07V-R | |||||

16(7/24) | 0.7 | 3.0 | 14.4 | 23 | |

14(7/22) | 0.8 | 3.6 | 24 | 35 | |

12(7/20) | 0.8 | 4.2 | 39 | 51 | |

10(7/18) | 0.8 | 4.7 | 58 | 71 | |

8(7/16) | 1 | 6.1 | 96 | 120 | |

6(7/14) | 1 | 7.2 | 154 | 170 | |

4(7/12) | 1.2 | 8.4 | 240 | 260 | |

2(7/10) | 1.2 | 9.5 | 336 | 350 | |

1(19/13) | 1.4 | 11.3 | 480 | 480 | |

2/0(19/11) | 1,4 | 12.6 | 672 | 680 | |

3/0(19/10) | 1,6 | 14.7 | 912 | 930 | |

4/0(37/12) | 1,6 | 16.2 | 1152 | 1160 | |

300MCM(37/11) | 1,8 | 18.1 | 1440 | 1430 | |

350MCM(37/10) | 2,0 | 20.2 | 1776 | 1780 | |

500MCM(61/11) | 2,2 | 22.9 | 2304 | 2360 | |

| 2.4 | 24.5 |

| 2940 | |

| 2.6 | 27.5 |

| 3740 | |

Introduction

In the realm of industrial electrical installations, selecting the appropriate cable is critical to ensuring safety, efficiency, and compliance with international standards. The H05V-R and H07V-R harmonized code industrial cables are widely used in various applications, from indoor installations to switchgear cabinets and underground systems. These cables, designed to meet stringent European standards, are particularly valued for their versatility and reliability in industrial plants, switching stations, and equipment designed for export to European markets.

Applications

The H05V-R and H07V-R cables are versatile, with applications including:

Indoor Installations: Ideal for cable ducts in buildings, ensuring safe and reliable power distribution.

Industrial Plants and Switching Stations: Their robust construction makes them suitable for demanding environments.

Underground Installations: The cables’ insulation and durability allow for safe underground use.

Switchboards and Distributor Boards: Used where thicker, multi-wire strands are required.

Export to European Markets: Designed to meet European standards, these cables are essential for equipment exported to Europe.

MRO (Maintenance, Repair, and Operations): Perfect for replacing wires in European-made equipment.

Advantages of H05V-R and H07V-R Cables

Compliance with International Standards: Their adherence to multiple standards ensures global applicability.

Versatility: Suitable for a wide range of applications, from low to high voltage.

Durability: The PVC insulation and copper conductors provide long-term reliability.

Environmental Compliance: RoHS compliance ensures eco-friendliness.

Flame Retardancy: Reduces fire risks in industrial settings.

Case Studies

Case Study 1: South African Manufacturing Plant Upgrade

A manufacturing facility in Johannesburg upgraded its electrical infrastructure to comply with European export standards. The plant required cables for its switchgear cabinets that could handle 450/750 volts and meet CE Low Voltage Directive standards. H07V-R cables (1 x 70 mm²) were selected due to their high voltage rating and compliance with VDE-0281 Part-3. The installation was completed without issues, and the cables’ flame-retardant properties ensured compliance with local safety regulations. The plant successfully passed an export audit, securing a contract with a European client.

Case Study 2: Underground Installation in a Cape Town Data Centre

A data centre in Cape Town required reliable cabling for an underground power distribution system. H05V-R cables (1 x 2.5 mm²) were chosen for their flexibility and ability to operate at -30°C to +80°C in static conditions. The cables were installed in ducts, connecting backup generators to critical systems. Their high insulation resistance (10 MΩ x km) ensured minimal power loss, and the project was completed on time, with the cables performing reliably for over two years.

Frequently Asked Questions

1. What is the difference between H05V-R and H07V-R cables?

The primary difference lies in their voltage ratings. H05V-R cables are rated for 300/500 volts, suitable for lighter applications, while H07V-R cables support 450/750 volts, making them ideal for higher voltage industrial uses.

2. Are these cables suitable for outdoor use?

While primarily designed for indoor and underground installations, H05V-R and H07V-R cables can be used outdoors if protected within conduits or ducts, as their PVC insulation is not UV-resistant.

3. How do these cables comply with South African regulations?

In South Africa, electrical installations must comply with SANS 10142-1. The H05V-R and H07V-R cables meet equivalent international standards (e.g., BS 6004, VDE-0281), which are recognised in South Africa, especially for industrial applications and exports.

4. Can these cables be used in high-temperature environments?

The cables can handle short-circuit temperatures up to +160°C and static temperatures up to +80°C, making them suitable for most industrial environments. However, prolonged exposure to extreme heat should be avoided.

5. Why are these cables preferred for European exports?

Their compliance with European standards like HD 21.3 S3, CEI 20-20/3, and the CE Low Voltage Directive ensures they meet the stringent requirements of European markets, making them ideal for equipment designed for export.

The H05V-R and H07V-R harmonized code industrial cables are a cornerstone of reliable electrical installations in industrial and export-oriented applications. Their robust construction, compliance with international standards, and versatility make them a preferred choice for indoor, underground, and switchgear applications. In South Africa, where industries are increasingly aligning with global standards, these cables play a vital role in ensuring safety and efficiency. Through case studies and detailed analysis, it is clear that H05V-R and H07V-R cables are not only technically sound but also practically proven in real-world scenarios. For engineers, electricians, and procurement managers, understanding these cables’ specifications and applications is essential for making informed decisions in industrial electrical projects.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430