Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H05V-U/H07V-U

Application and Description

H05 V-U/(H)05 V-U

These insulated wires are determined for the installation to the inside of apparatus as well as for the protective laying to the lightings, in dry rooms, in production facilities, switch and distributor boards, in tubes, under and surface mounting of plasters.

H07 V-U/(H)07 V-U

These insulated wires are suitable for laying tubes, under and surface mounting of plasters and also in closed installation conduits. These are not allowed to install for direct laying in cable trays, channels or tanks. These types are permitted for the inner wiring of equipment, distributor and switchboards and also for protective laying to the lightings with a nominal voltage up to 1000 V alternating current or up to 750 V direct current against ground.

Standard and Approval

HD 21.3 S3, VDE-0281 Part-3, CEI20-20/3,

CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant

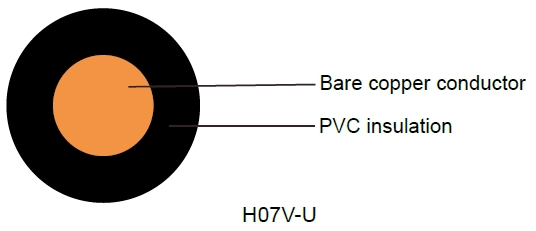

Cable Construction

- Solid bare copper single wire

- Solid to DIN VDE 0295 cl-1 and IEC 60228 cl-1

- Special PVC TI1 core insulation

- Cores to VDE-0293 colors on chart

- H05V-U (20, 18 & 17 AWG)

- H07V-U (16 AWG and Larger)

Technical Characteristics

- Working voltage: 300/500v (H05V-U)

- Working voltage: 450/750v (H07V-U)

- Test voltage: 2000V(H05V-U)/2500V (H07V-U)

- Flexing bending radius: 15 x Ø

- Static bending radius: 15 x Ø

- Flexing temperature: -5º C to +70º C

- Static temperature: -30º C to +90º C

- Short circuit temperature: +160º C

- Flame retardant: IEC 60332.1

- Insulation resistance: 10 MΩ x km

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² | NOMINAL THICKNESS OF INSULATION MM | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT KG/KM | NOMINAL WEIGHT KG/KM |

|---|---|---|---|---|---|

20 | 0.6 | 2.1 | 4.8 | 9 | |

18 | 0.6 | 2.2 | 7.2 | 11 | |

17 | 0.6 | 2.4 | 9.6 | 14 | |

16 | 0.7 | 2.9 | 14.4 | 21 | |

14 | 0.8 | 3.5 | 24.0 | 33 | |

12 | 0.8 | 3.9 | 38.0 | 49 | |

10 | 0.8 | 4.5 | 58.0 | 69 | |

8 | 1.0 | 5.7 | 96.0 | 115 |

Introduction

In the realm of electrical engineering and industrial applications, the selection of appropriate wiring is critical to ensure safety, reliability, and efficiency. Among the various types of cables available, the H05V-U and H07V-U harmonized code industrial cables stand out for their versatility and adherence to stringent international standards. These insulated wires, designed for specific applications in dry environments, are widely used in South Africa and globally for internal wiring of equipment, lighting installations, and switchboard connections.

Applications

The H05V-U and H07V-U cables are designed for specific applications, primarily in dry environments. Their key uses include:

Internal Wiring of Apparatus: Both cables are ideal for the internal wiring of electrical equipment, ensuring reliable connections within devices.

Lighting Installations: They are used for protective laying to lighting systems in dry rooms, production facilities, and commercial buildings.

Switch and Distributor Boards: The cables are commonly employed in switchboards and distributor boards, providing safe and efficient power distribution.

Installation in Tubes and Conduits: H07V-U cables are particularly suited for laying in tubes and closed conduits, while H05V-U cables can also be surface-mounted or installed under plaster.

These cables are not suitable for direct laying in cable trays, channels, or tanks, as their design prioritizes fixed installations over flexible or exposed applications.

Case Studies

Case Study 1: Industrial Lighting Upgrade in a Johannesburg Factory

A manufacturing facility in Johannesburg undertook a lighting upgrade to improve energy efficiency and workplace safety. The project required reliable wiring for new LED lighting systems installed in dry production areas. H05V-U cables (17 AWG, 1 mm²) were selected for their 300/500 V rating and suitability for protective laying to lighting. The cables were installed in tubes and surface-mounted on plaster, ensuring compliance with safety standards. The project was completed without incidents, and the cables’ flame-retardant properties provided additional safety in the industrial environment. The facility reported a 20% reduction in energy consumption, partly attributed to the efficient wiring system.

Case Study 2: Switchboard Installation in a Cape Town Commercial Building

A commercial building in Cape Town required a new switchboard installation to support an expanded office space. H07V-U cables (12 AWG, 4 mm²) were chosen for their higher 450/750 V rating and suitability for closed installation conduits. The cables were used for internal wiring within the switchboard, connecting various circuits to ensure reliable power distribution. The installation complied with SABS and CE standards, and the cables’ solid copper conductors provided low resistance, minimizing power losses. The project was completed on schedule, and the switchboard has operated reliably for over two years.

Frequently Asked Questions

1. What is the difference between H05V-U and H07V-U cables?

The primary difference lies in their voltage ratings and applications. H05V-U cables are rated for 300/500 V and are suitable for internal wiring of apparatus and lighting in dry environments. H07V-U cables, with a 450/750 V rating, are designed for higher voltage applications and can be used in closed conduits, switchboards, and lighting systems up to 1000 V AC or 750 V DC.

2. Can these cables be used outdoors?

No, H05V-U and H07V-U cables are designed for dry environments and are not suitable for outdoor use or direct laying in cable trays, channels, or tanks. For outdoor applications, cables with weather-resistant insulation, such as those with XLPE or rubber insulation, should be considered.

3. Are these cables flexible?

These cables feature solid copper conductors, making them less flexible than stranded cables. They are designed for fixed installations, with a bending radius of 15 x the cable diameter, suitable for static applications.

4. How do these cables comply with South African regulations?

In South Africa, electrical installations must comply with SABS standards, which align with international standards like those governing H05V-U and H07V-U cables. These cables meet HD 21.3 S3, VDE-0281, and CE Low Voltage Directive requirements, ensuring they are safe and reliable for use in South African industrial and commercial settings.

5. What is the significance of ROHS compliance?

ROHS compliance ensures that the cables are free from hazardous substances, such as lead and mercury, making them environmentally friendly and safe for use in applications where environmental regulations are stringent.

Conclusion

The H05V-U and H07V-U harmonized code industrial cables are essential components in modern electrical installations, offering reliability, safety, and compliance with international standards. Their solid copper conductors, PVC TI1 insulation, and adherence to standards like HD 21.3 S3 and the CE Low Voltage Directive make them ideal for a range of applications, from lighting to switchboard wiring. In South Africa, these cables are widely used in industrial and commercial projects, as demonstrated by case studies in Johannesburg and Cape Town.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430