Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H05V2-K / H07V2-K

Application and Description

These special heat-resistant flexible single-conductor hook-up wires are ideal for use in power current installation, switch cabinets, motors and transformers which are subject to direct contact with high temperature (e.g. varnishing machines and drying towers etc.). These are also suitable for inside wiring of electrical equipments such as lighting and heating apparatus.

Standard and Approval

HD 21.7 S2

CEI 20-20, CEI20-52

VDE-0281 Part-7

CE Low Voltage Directive 73/23/EEC and 93/68/EEC

ROHS compliant

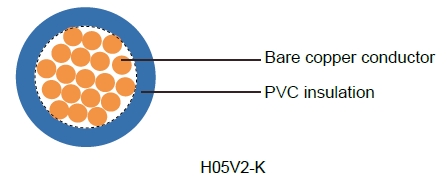

Cable Construction

Fine bare copper strands |

Strands to VDE-0295 Class-5, IEC 60228 Class-5, BS 6360 cl. 5 and HD 383 |

Special heat resistant PVC TI3 core insulation to DIN VDE 0281 part 7 |

Cores to VDE-0293 colors |

H05V2-K (20, 18 & 17 AWG) |

H07V2-K (16 AWG and Larger) |

Technical Characteristics

WORKING VOLTAGE | 300/500v (H05V2-K)/ 450/750v (H07V2-K) |

|---|---|

TEST VOLTAGE | 2000 volts |

FLEXING BENDING RADIUS | 10-15 x Ø |

STATIC BENDING RADIUS | 10-15 x Ø |

FLEXING TEMPERATURE | +5 ºC to +90 ºC |

STATIC TEMPERATURE | -10 ºC to +105 ºC |

FLAME RETARDANT | IEC 60332.1 |

INSULATION RESISTANCE | 20 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA | NOMINAL THICKNESS OF INSULATION | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT | NOMINAL WEIGHT |

|---|---|---|---|---|---|

# X MM² | MM | MM | KG/KM | KG/KM | |

H05V2-K | |||||

20(16/32) | 0.6 | 2.5 | 4.8 | 8.7 | |

18(24/32) | 0.6 | 2.7 | 7.2 | 11.9 | |

17(32/32) | 0.6 | 2.8 | 9.6 | 14.0 | |

H07V2-K | |||||

16(30/30) | 0,7 | 3.4 | 14.4 | 20 | |

14(50/30) | 0,8 | 4.1 | 24 | 33.3 | |

12(56/28) | 0,8 | 4.8 | 38 | 48.3 | |

10(84/28) | 0,8 | 5.3 | 58 | 68.5 | |

8(80/26) | 1,0 | 6.8 | 96 | 115 | |

6(128/26) | 1,0 | 8.1 | 154 | 170 | |

4(200/26) | 1,2 | 10.2 | 240 | 270 | |

2(280/26) | 1,2 | 11.7 | 336 | 367 | |

1(400/26) | 1,4 | 13.9 | 480 | 520 | |

2/0(356/24) | 1,4 | 16 | 672 | 729 | |

3/0(485/24) | 1,6 | 18.2 | 912 | 962 | |

4/0(614/24) | 1,6 | 20.2 | 1115 | 1235 | |

300 MCM (765/24) | 1,8 | 22.5 | 1440 | 1523 | |

350 MCM (944/24) | 2,0 | 24.9 | 1776 | 1850 | |

500MCM(1225/24) | 2,2 | 28.4 | 2304 | 2430 | |

Introduction

In the realm of industrial electrical installations, the choice of cabling is critical to ensuring safety, reliability, and efficiency. Among the myriad options available, H05G-K and H07G-K harmonized code industrial cables stand out for their versatility and robust performance in demanding environments. These cables, designed for internal wiring in switchboards, distributor boards, and other industrial applications, are engineered to meet stringent European standards, making them a preferred choice in South Africa and beyond.

Applications of H05G-K and H07G-K Cables

H05G-K and H07G-K cables are designed for internal wiring in environments requiring high flexibility and reliability. Common applications include:

Switchboards and Distributor Boards: The cables’ flexibility and high voltage ratings make them ideal for wiring complex switchgear and distribution systems.

Industrial Installations: They are used in manufacturing plants, data centres, and other facilities where reliable power distribution is critical.

Laying in Tubes or Under Plaster: Their robust insulation allows for safe installation in conduits or embedded within building structures.

South African Context: In South Africa, these cables are widely used in mining, manufacturing, and renewable energy sectors due to their ability to withstand harsh environmental conditions, including high temperatures and dust exposure.

Case Studies

Case Study 1: Mining Sector in South Africa

In a large-scale mining operation in Mpumalanga, South Africa, a leading mining company required reliable cabling for its underground control panels. The harsh environment, characterized by high temperatures, dust, and frequent vibrations, demanded cables with exceptional durability and flexibility. H07G-K cables (16 mm²) were selected for their high voltage rating (450/750V) and wide temperature range (-40°C to +110°C). The cables were installed in conduits within the control panels, ensuring safe and efficient power distribution. Over a two-year period, the cables demonstrated zero failures, contributing to uninterrupted operations and enhanced safety.

Case Study 2: Renewable Energy Installation in the Northern Cape

A solar power plant in the Northern Cape utilized H05G-K cables (1 mm²) for internal wiring within its inverter systems. The cables’ flame-retardant properties and high insulation resistance were critical in preventing fire hazards and ensuring reliable performance in the region’s extreme heat. The project, completed in 2024, reported a 15% reduction in maintenance costs compared to previous installations using non-harmonized cables, highlighting the long-term benefits of H05G-K cables.

Frequently Asked Questions

1. What is the difference between H05G-K and H07G-K cables?

The primary difference lies in their voltage ratings. H05G-K cables are rated for 300/500V, making them suitable for lower voltage applications, while H07G-K cables are rated for 450/750V, ideal for higher voltage requirements. Additionally, H07G-K cables typically have thicker insulation to accommodate the higher voltage, resulting in slightly larger diameters.

2. Are these cables suitable for outdoor use?

While H05G-K and H07G-K cables are primarily designed for indoor applications, such as wiring in switchboards or under plaster, they can be used in protected outdoor environments if installed in conduits or other protective enclosures. Their temperature range (-40°C to +110°C) makes them adaptable to South Africa’s varied climate, but direct exposure to UV radiation or moisture should be avoided.

3. How do these cables ensure safety in industrial settings?

The cables’ flame-retardant properties (IEC 60332.1) and high insulation resistance (10 MΩ x km) minimize fire risks and electrical faults. Their compliance with European safety standards and ROHS regulations further ensures they are safe for use in industrial environments.

4. Can these cables be used in residential installations?

Yes, H05G-K and H07G-K cables can be used in residential settings for internal wiring, particularly in applications requiring high flexibility, such as home automation systems or complex lighting setups. However, their cost may be higher than standard residential cables, so they are typically reserved for specialized applications.

5. How do I select the appropriate cable size?

The choice of cable size depends on the current-carrying capacity, voltage requirements, and installation conditions. For example, a 0.5 mm² H05G-K cable is suitable for low-current applications, while a 120 mm² H07G-K cable can handle high-power loads. Consulting with a qualified electrician and referring to the cable parameters (e.g., nominal copper weight and overall diameter) is recommended.

Advantages and Limitations

Advantages

High Flexibility: The Class-5 copper conductors allow for easy installation in tight spaces.

Wide Temperature Range: Suitable for South Africa’s diverse climate, from coastal humidity to inland heat.

Flame Retardancy: Enhances safety in industrial environments.

Compliance with Standards: Ensures reliability and compatibility with global regulations.

Limitations

Cost: Harmonized cables may be more expensive than non-standard alternatives, which could be a consideration for budget-conscious projects.

Not UV-Resistant: Direct outdoor exposure without protection may degrade the insulation over time.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430