Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H05V2V2-F/ H05V2V2H2-F

Application and Description

These cables are suitable for domestic premises, kitchen, office for light service or light portable apparatuses. With their special insulation and sheath compounds these cables are adapt for apparatus in kitchen and heating and for use in zones with high temperature (like lighting system apparatuses) without contact with warm parts and radiations.

Unsuitable for outdoor use, in industrial and agricultural buildings or non-domestic portable tools. The maximum conductor temperature in normal use:90°C.While high temperature use, skin contact must be avoided.

Standard and Approval

CEI 20-20/12, CEI 20-35 (EN60332-1) / CEI 20-37 (EN50267), CENELEC HD 21.12 S1 /EN50265-2-1

Cable Construction

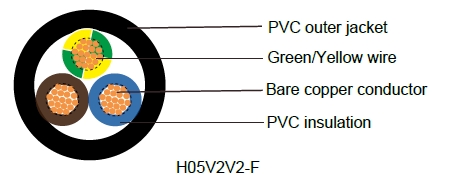

Technical Characteristics

Bare copper fine wire conductor |

Stranded to DIN VDE 0295 cl. 5, IEC 60228 cl. 5 and HD 383 |

PVC core insulation TI3 to VDE-0281 Part 1 |

Green-yellow grounding (3 conductors and above) |

Color coded to VDE-0293-308 |

PVC outer jacket TM3 |

Working voltage | 300/500 volts |

Test voltage | 2000 volts |

Flexing bending radius | 15 x O |

Static bending radius | 4 x O |

Flexing temperature | +5o C to +90o C |

Static temperature | -40o C to +90o C |

Short circuit temperature | +160o C |

Flame retardant | IEC 60332.1 |

Insulation resistance | 20 MΩ x km |

Cable Parameter

AWG | No. of Cores x Nominal Cross Sectional Area # x mm² | Nominal Thickness of Insulation mm | Nominal Thickness of Sheath mm | Nominal Overall Diameter mm | Nominal Copper Weight kg/Km | Nominal Weight kg/Km |

|---|---|---|---|---|---|---|

H05V2V2-F | ||||||

18(24/32) | 2 x 0.75 | 0.6 | 0.8 | 6.2 | 14.4 | 54.2 |

18(24/32) | 3 x 0.75 | 0.6 | 0.8 | 6.6 | 21.6 | 65 |

18(24/32) | 4 x 0.75 | 0.6 | 0.8 | 7.1 | 29 | 77.7 |

18(24/32) | 5 x 0.75 | 0.6 | 0.9 | 8 | 36 | 97.3 |

17(32/32) | 2 x 1.00 | 0.6 | 0.8 | 6.4 | 19 | 60.5 |

17(32/32) | 3 x 1.00 | 0.6 | 0.8 | 6.8 | 29 | 73.1 |

17(32/32) | 4 x 1.00 | 0.6 | 0.9 | 7.6 | 38 | 93 |

17(32/32) | 5 x 1.00 | 0.6 | 0.9 | 8.3 | 48 | 111.7 |

16(30/30) | 2 x 1.50 | 0.7 | 0.8 | 7.4 | 29 | 82.3 |

16(30/30) | 3 x 1.50 | 0.7 | 0.9 | 8.1 | 43 | 104.4 |

16(30/30) | 4 x 1.50 | 0.7 | 1.0 | 9 | 58 | 131.7 |

16(30/30) | 5 x 1.50 | 0.7 | 1.1 | 10 | 72 | 163.1 |

14(30/50) | 2 x 2.50 | 0.8 | 1.0 | 9.2 | 48 | 129.1 |

14(30/50) | 3 x 2.50 | 0.8 | 1.1 | 10 | 72 | 163 |

14(30/50) | 4 x 2.50 | 0.8 | 1.1 | 10.9 | 96 | 199.6 |

14(30/50) | 5 x 2.50 | 0.8 | 1.2 | 12.4 | 120 | 245.4 |

12(56/28) | 3 x 4.00 | 0.8 | 1.2 | 11.3 | 115 | 224 |

12(56/28) | 4 x 4.00 | 0.8 | 1.2 | 12.5 | 154 | 295 |

12(56/28) | 5 x 4.00 | 0.8 | 1.4 | 13.7 | 192 | 361 |

10(84/28) | 3 x 6.00 | 0.8 | 1.1 | 13.1 | 181 | 328 |

10(84/28) | 4 x 6.00 | 0.8 | 1.3 | 13.9 | 230 | 490 |

H05V2V2H2-F | ||||||

18(24/32) | 2 x 0.75 | 0.6 | 0.8 | 4.2 x 6.8 | 14.1 | 48 |

17(32/32) | 2 x 1.00 | 0.6 | 0.8 | 4.4 x 7.2 | 19 | 57 |

Introduction

In the world of electrical engineering, where safety and reliability are paramount, the H05V2V2-F and its flat variant H05V2V2H2-F stand out as versatile performers. These heat-resistant flexible cables are designed to handle elevated temperatures without compromising performance, making them ideal for modern households and workplaces. Originating from European standards but widely adopted globally, including in South Africa, these cables bridge the gap between everyday wiring needs and environments where heat could otherwise pose a risk.

Imagine powering your kitchen appliances or office lighting systems in a hot South African summer—the H05V2V2-F ensures seamless operation. With special PVC insulation and sheathing compounds, it can withstand conductor temperatures up to 90°C in normal use, far surpassing standard cables. This article delves into its technical details, practical applications, key benefits, and even touches on South African scenarios where it's making a difference. Whether you're an electrician, homeowner, or simply curious about the tech behind your plugs, let's explore this unsung hero of electrical infrastructure.

What is the H05V2V2-F Cable?

The H05V2V2-F (round) and H05V2V2H2-F (flat) are multi-core flexible cables constructed with bare copper fine wire conductors, stranded according to standards like DIN VDE 0295 class 5 and IEC 60228 class 5. The cores are insulated with PVC TI3 material, colour-coded per VDE-0293-308, and include a green-yellow grounding core for three or more conductors. The outer jacket is made of PVC TM3, providing durability and heat resistance.

These cables comply with rigorous standards such as CEI 20-20/12, CEI 20-35 (EN60332-1), CEI 20-37 (EN50267), and CENELEC HD 21.12 S1/EN50265-2-1, ensuring flame retardancy and safety. They're unsuitable for outdoor, industrial, or agricultural use but excel in light-duty indoor scenarios.

Application Scenarios

The H05V2V2-F shines in domestic and light commercial settings. It's perfect for wiring in kitchens, offices, and homes where light portable appliances are used. Think of connecting ovens, heaters, or lighting fixtures—areas with high ambient temperatures but no direct contact with hot surfaces or radiation.

In South Africa, with its warm climate and growing urban infrastructure, these cables are commonly employed in residential wiring for air conditioners and kitchen gadgets. They're also used in office lighting systems to handle heat from prolonged use. However, avoid outdoor applications, industrial machinery, or agricultural tools, as they're not built for heavy mechanical stress or exposure.

Advantages

What sets the H05V2V2-F apart? Its heat-resistant PVC compounds allow operation at 90°C, reducing the risk of melting or failure in warm zones. The flexible design (class 5 stranding) makes installation easy, even in tight spaces. Flame retardancy adds a safety layer, while the insulation prevents short circuits.

Compared to standard cables, it offers better longevity in heated environments, potentially lowering maintenance costs. In South Africa, where power reliability is crucial amid load-shedding, this cable ensures appliances run smoothly without overheating issues.

Frequently Asked Questions (FAQs)

Q: Can the H05V2V2-F be used outdoors in South Africa?

A: No, it's designed for indoor use only. South Africa's variable weather makes it unsuitable for external applications.

Q: What makes this cable heat-resistant?

A: Special PVC compounds in the insulation and sheath allow it to operate at up to 90°C, but avoid skin contact when hot.

Q: Is it safe for kitchen appliances?

A: Yes, it's ideal for light portable devices in kitchens, like toasters or mixers, but not for direct heat exposure.

Q: How does it compare to standard PVC cables?

A: It handles higher temperatures (90°C vs. 70°C) and is more flexible, but costs slightly more due to specialised materials.

The H05V2V2-F cable exemplifies how subtle innovations in materials science enhance daily life. From powering South African homes to supporting office efficiency, its heat-resistant properties ensure reliability in a warming world. As technology evolves, such cables will play a key role in sustainable electrical systems. For more on electrical advancements, keep exploring!

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430