Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H05VV5-F(NYSLYÖ-JZ)

Application and Description

These cables are suitable for dry, damp and wet locations but not in the open-air. They are used as screened termination and connection cable in the control, measuring and signal technology. The copper braiding optimises protection against external interferences, like electromagnetic fields and stray frequencies. Suitable as a signal and impulse cable for control and inspection of industrial plants, machinery and working processes.

Standard and Approval

HD 21.13 S1

VDE-0281 Part-13

CEI 20-20/13

CEI 20-35 (EN60332-1)

CEI 20-52

UL 2464

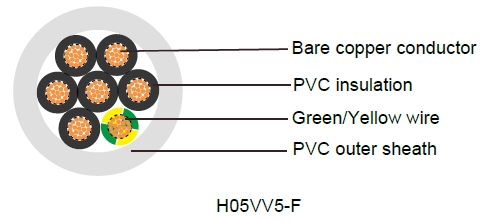

Cable Construction

Fine bare copper strands |

Strands to VDE-0295 Class-5, IEC 60228 Class-5 |

PVC insulation T12 to DIN VDE 0281 part 1 |

Green-yellow grounding (3 conductors and above) |

Cores to VDE-0293 colors |

PVC sheath TM5 to DIN VDE 0281 part 1 |

Technical Characteristics

WORKING VOLTAGE | 300/500v |

|---|---|

TEST VOLTAGE | 2000volts |

FLEXING BENDING RADIUS | 7.5 x Ø |

STATIC BENDING RADIUS | 4 x Ø |

FLEXING TEMPERATURE | -5 ºC to +70 ºC |

STATIC TEMPERATURE | -40 ºC to +70 ºC |

SHORT CIRCUIT TEMPERATURE | +150 ºC |

FLAME RETARDANT | IEC 60332.1 |

INSULATION RESISTANCE | 20 MΩ x km |

Introduction

The H05VV5-F (NYSLYÖ-JZ) harmonized code industrial cable is a versatile and robust solution designed for control, measuring, and signal applications in industrial environments. Renowned for its durability and resistance to external electromagnetic interference, this cable is widely used across various sectors, including manufacturing, automation, and process control.

Applications

The H05VV5-F cable is designed for use in control, measuring, and signal technology, particularly in environments requiring reliable signal transmission. Key applications include:

Industrial Automation: Connecting sensors, actuators, and control units in automated production lines.

Machinery Control: Facilitating precise control of industrial machinery, such as conveyor systems and robotic arms.

Process Monitoring: Transmitting signals for monitoring and controlling industrial processes, such as temperature and pressure regulation.

Signal and Impulse Transmission: Ensuring accurate data transfer in measurement and inspection systems.

The cable’s copper braiding makes it particularly effective in environments with high electromagnetic interference, such as factories with heavy machinery or power plants.

Benefits of the H05VV5-F Cable

The H05VV5-F cable offers several advantages that make it a preferred choice in industrial settings:

Electromagnetic Interference Protection: The copper braiding shields the cable from EMI, ensuring reliable signal transmission.

Flexibility: Class-5 copper conductors and PVC insulation allow the cable to bend without compromising performance, ideal for dynamic applications.

Durability: The PVC sheath provides resistance to mechanical stress, moisture, and chemicals, extending the cable’s lifespan.

Versatility: Available in various core counts and cross-sectional areas, the cable can be tailored to specific needs.

Safety: Compliance with flame-retardant standards and high insulation resistance ensures safe operation in critical environments.

Case Studies in South Africa

Case Study 1: Mining Industry in Gauteng

In a large gold mine in Gauteng, South Africa, the H05VV5-F cable was implemented to connect control systems for underground conveyor belts. The mine’s environment, characterized by high levels of electromagnetic interference from heavy machinery, posed challenges for signal integrity. The H05VV5-F’s copper braiding effectively mitigated EMI, ensuring reliable communication between sensors and control units. The cable’s flexibility (7.5 x diameter bending radius) allowed it to navigate tight spaces, while its flame-retardant properties complied with strict safety regulations. The use of a 5 x 1.5 mm² configuration provided sufficient capacity for signal transmission, reducing downtime and improving operational efficiency.

Case Study 2: Manufacturing Plant in Durban

A manufacturing plant in Durban producing automotive components integrated the H05VV5-F cable into its robotic assembly line. The cable’s ability to operate in damp conditions was critical, as the plant occasionally experienced high humidity. A 12 x 0.75 mm² configuration was chosen for its balance of flexibility and signal capacity. The cable’s PVC insulation and sheath withstood mechanical stress from frequent movements, while its EMI shielding ensured accurate data transmission to robotic controllers. This implementation reduced maintenance costs and enhanced production reliability.

Frequently Asked Questions

1. What environments is the H05VV5-F cable suitable for?

The H05VV5-F cable is designed for dry, damp, and wet locations but is not suitable for open-air exposure. It is ideal for indoor industrial environments, such as factories, processing plants, and control rooms, where protection from EMI is necessary.

2. Why is the copper braiding important?

The copper braiding shields the cable from electromagnetic interference and stray frequencies, ensuring reliable signal transmission in environments with high electrical noise, such as near heavy machinery or power lines.

3. What are the temperature limitations of the H05VV5-F cable?

The cable can operate in flexing conditions from -5°C to +70°C and in static conditions from -40°C to +70°C. It can also withstand short-circuit temperatures up to +150°C, making it suitable for a wide range of industrial applications.

4. How does the H05VV5-F cable ensure safety?

The cable complies with IEC 60332.1 for flame retardancy, preventing fire propagation. Its high insulation resistance (20 MΩ x km) and robust PVC insulation reduce the risk of electrical faults, while the green-yellow grounding conductor enhances safety in multi-core configurations.

5. Can the H05VV5-F cable be used in South African industries?

Yes, the H05VV5-F cable is widely used in South African industries, including mining, manufacturing, and automation. Its compliance with international standards and ability to withstand harsh conditions make it suitable for the country’s diverse industrial landscape.

6. How do I choose the right configuration for my application?

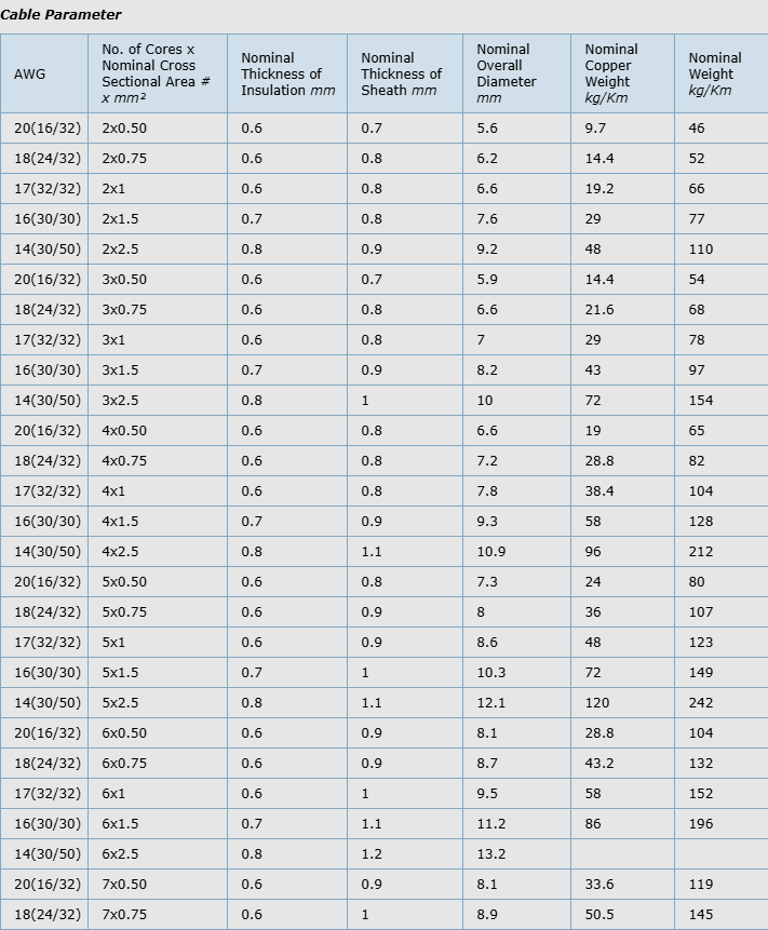

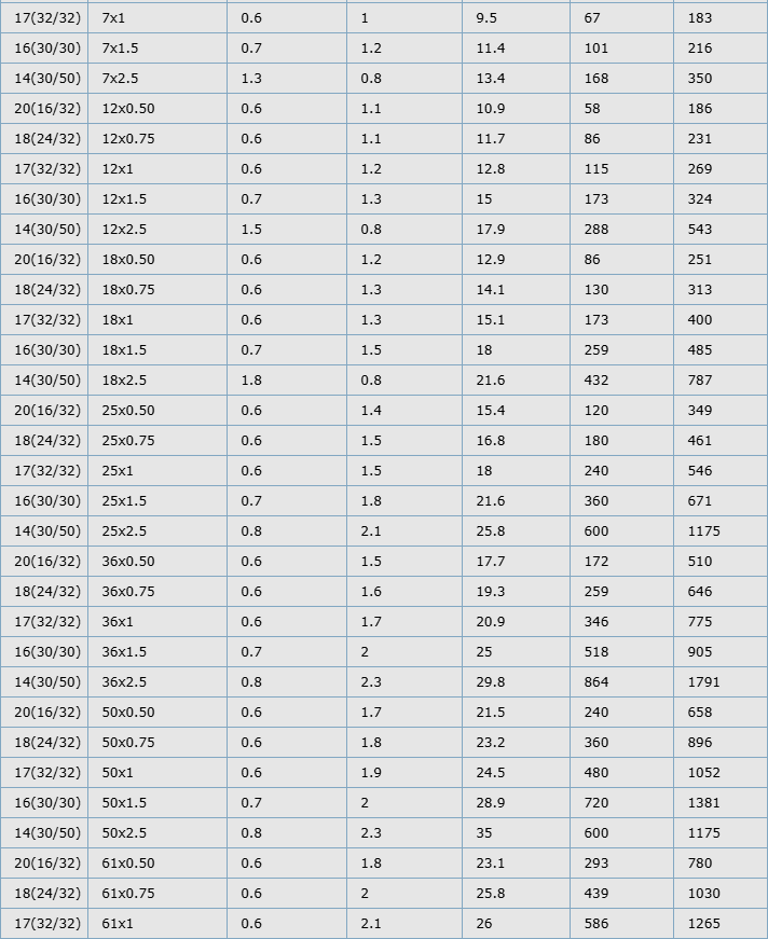

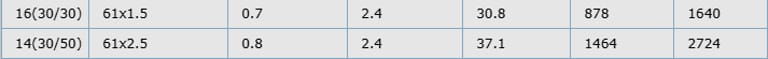

The choice of configuration depends on the number of signals, current requirements, and installation conditions. For example, a 2 x 0.50 mm² cable is suitable for low-signal applications, while a 25 x 1.5 mm² cable is better for complex systems requiring multiple connections. Consult with a supplier or engineer to select the appropriate core count and cross-sectional area.

The H05VV5-F (NYSLYÖ-JZ) harmonized code industrial cable is a reliable and versatile solution for control, measuring, and signal applications in industrial environments. Its robust construction, EMI protection, and compliance with international standards make it a preferred choice for industries worldwide, including South Africa’s mining and manufacturing sectors. By offering flexibility, durability, and safety, the H05VV5-F cable ensures efficient and reliable performance in demanding conditions. Whether used in automated production lines or process monitoring systems, this cable continues to play a critical role in advancing industrial operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430