Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H05Z-K/H07Z-K

Application and Description

These cables are designed for the internal wiring of switchboards and distributor boards with an alternating nominal voltage up to 1000 Volts or a direct voltage up to 750 volts. Generally install in pipes or ducts and internal wiring of appliances with maximum operating temperature of 90º C, and generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gasses when burnt which is particularly important where electronic equipment is installed.

Standard and Approval

HD 22.9 S2, VDE-0282 Part-9, BS 7211, IEC 60754-2, EN 50267, VDE 0482-267, CE Low Voltage

Directive 73/23/EEC and 93/68/EEC, ROHS compliant

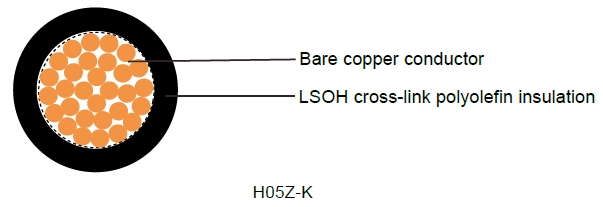

Cable Construction

- Fine bare copper strands

- Strands to VDE-0295 Class-5, IEC 60228 Class-5 BS 6360 cl. 5, HD 383

- Cross-link polyolefin EI5 core insulation

- LSOH - low smoke, zero halogen

Technical Characteristics

- Working voltage: 300/500v (H05Z-K), 450/750v (H07Z-K)

- Test voltage: 2500 volts

- Flexing bending radius: 8 x Ø

- Static bending radius: 8 x Ø

- Flexing temperature: -15º C to +90º C

- Static temperature: -40º C to +90º C

- Flame retardant: IEC 60332.1

- Insulation resistance: 10 MΩ x km

- Smoke density acc. to EN 50268 / IEC 61034

- Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

- Flame test: flame-retardant acc. to EN 50265-2-1, IEC 60332.1

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # XMM² | NOMINAL THICKNESS OF INSULATION MM | NOMINAL OVERALL DIAMETER MM | NOMINAL COPPER WEIGHT KG/KM | NOMINAL WEIGHT KG/KM |

|---|---|---|---|---|---|

H05Z-K | |||||

20(16/32) | 0.6 | 2.3 | 4.8 | 9 | |

18(24/32) | 0.6 | 2.5 | 7.2 | 12.4 | |

17(32/32) | 0.6 | 2.6 | 9.6 | 15 | |

H07Z-K | |||||

16(30/30) | 0.7 | 3.5 | 14.4 | 24 | |

14(50/30) | 0.8 | 4 | 24 | 35 | |

12(56/28) | 0.8 | 4.8 | 38 | 51 | |

10(84/28) | 0.8 | 6 | 58 | 71 | |

8(80/26) | 1.0 | 6.7 | 96 | 118 | |

6(128/26) | 1.0 | 8.2 | 154 | 180 | |

4(200/26) | 1.2 | 10.2 | 240 | 278 | |

2(280/26) | 1.2 | 11.5 | 336 | 375 | |

1(400/26) | 1.4 | 13.6 | 480 | 560 | |

2/0(356/24) | 1.4 | 16 | 672 | 780 | |

3/0(485/24) | 1.6 | 18.4 | 912 | 952 | |

4/0(614/24) | 1.6 | 20.3 | 1152 | 1200 | |

300 MCM (765/24) | 1.8 | 22.7 | 1440 | 1505 | |

350 MCM (944/24) | 2.0 | 25.3 | 1776 | 1845 | |

500MCM(1225/24) | 2.2 | 28.3 | 2304 | 2400 | |

Introduction

In the realm of industrial electrical applications, the choice of cabling is critical to ensuring safety, efficiency, and compliance with stringent regulations. Among the myriad options available, H05Z-K and H07Z-K harmonized code industrial cables stand out for their versatility, safety features, and compliance with international standards. These cables, designed for internal wiring in switchboards, distributor boards, and appliances, are engineered to operate under demanding conditions while prioritising safety in environments where smoke and toxic fumes pose significant risks.

Benefits of H05Z-K and H07Z-K Cables

Enhanced Safety: The LSOH properties significantly reduce risks in fire scenarios, protecting both human life and sensitive equipment.

Compliance with Standards: Adherence to international and South African standards ensures reliability and legal compliance.

Flexibility and Durability: The fine copper strands and robust insulation make these cables ideal for complex installations.

Environmental Adaptability: The wide temperature range suits South Africa’s diverse climatic conditions, from coastal humidity to inland extremes.

Versatility: Suitable for a wide range of applications, from residential to industrial settings.

Case Studies

Case Study 1: Upgrading a Johannesburg Data Centre

A major data centre in Johannesburg underwent a cabling upgrade to comply with stricter fire safety regulations. The facility, housing critical servers for a financial institution, required cables that minimised smoke and toxic gas emissions. H07Z-K cables (1 x 16 mm²) were selected for their LSOH properties and compliance with IEC 60332.1. The installation, completed in 2024, reduced fire-related risks and ensured uninterrupted operation of sensitive equipment, even under high-load conditions. The project adhered to SANS 10142-1, earning approval from local authorities.

Case Study 2: Cape Town Hospital Retrofit

A hospital in Cape Town retrofitted its electrical infrastructure to enhance patient safety. H05Z-K cables (1 x 1 mm²) were used for internal wiring in operating theatres and intensive care units. The cables’ low smoke emission and zero halogen properties were critical in maintaining air quality during potential fire incidents, protecting vulnerable patients. The project, completed in 2023, demonstrated the cables’ reliability in high-stakes environments, aligning with South African health and safety standards.

Frequently Asked Questions

1. What are the main differences between H05Z-K and H07Z-K cables?

H05Z-K cables are rated for 300/500 V, suitable for lighter applications, while H07Z-K cables are rated for 450/750 V, designed for higher voltage demands. The H07Z-K also supports larger cross-sectional areas, accommodating heavier loads.

2. Why are LSOH cables preferred in public buildings?

LSOH cables, like H05Z-K and H07Z-K, produce minimal smoke and no corrosive halogen gases when burnt. This reduces risks to human health and damage to electronic equipment, making them ideal for schools, hospitals, and government buildings.

3. Are these cables suitable for outdoor use?

While primarily designed for internal wiring, H05Z-K and H07Z-K cables can be used in protected outdoor installations (e.g., within conduits) due to their wide temperature range (-40°C to +90°C). However, they are not UV-resistant, so additional protection is required for prolonged outdoor exposure.

4. How do these cables comply with South African regulations?

The cables meet SANS 10142-1 requirements for low-voltage installations and align with international standards like IEC and EN, ensuring compliance with South African safety and performance regulations.

5. What is the significance of the Class-5 conductor classification?

Class-5 conductors consist of fine copper strands, offering high flexibility. This makes H05Z-K and H07Z-K cables ideal for installations requiring tight bends or frequent movement, such as in appliances or confined spaces.

6. Can these cables be used in high-temperature environments?

Yes, the cables are rated for operating temperatures up to 90°C, making them suitable for appliances and environments with elevated temperatures, such as industrial machinery or server rooms.

H05Z-K and H07Z-K harmonized code industrial cables represent a pinnacle of safety and performance in electrical wiring. Their low smoke, zero halogen properties, combined with robust construction and compliance with international standards, make them indispensable in environments where safety is non-negotiable. In South Africa, their adoption in critical infrastructure projects underscores their reliability and versatility. By addressing fire safety concerns and supporting a wide range of applications, these cables are poised to play a significant role in the country’s industrial and commercial landscape. Whether in data centres, hospitals, or public buildings, H05Z-K and H07Z-K cables offer a future-proof solution for safe and efficient electrical installations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430