Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H05Z-U/H07Z-U

APPLICATION AND DESCRIPTION

These BS 7211 Standards cables are designed for the internal wiring of switchboards and distributor boards with an alternating nominal voltage up to 1000 Volts or a direct voltage up to 750 volts. Generally install in pipes or ducts and internal wiring of appliances with maximum operating temperature of 90º C, and generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gasses when burnt which is particularly important where electronic equipment is installed.

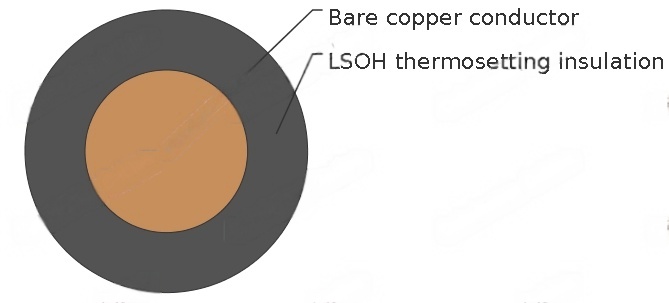

CABLE CONSTRUCTION

Solid bare copper

Single wire to IEC 60228 Cl-1

Cross-link polyolefin EI5 core insulation

LSOH - low smoke, zero halogen

INSULATION COLOUR

Green/Yellow, Black, Blue, Brown, Red, White, Yellow, Grey, Violet

TECHNICAL CHARACTERISTICS

Working voltage : 300/500v (H05Z-U) ; 450/750v (H07Z-U)

Test voltage : 2000 / 2500 volts

Flexing bending radius : 15 x Ø

Static bending radius : 10 x Ø

Flexing temperature : +5º C to +90º C

Short circuit temperature : +250º C

Insulation resistance : 10 MΩ x km

Flame retardant : IEC 60332.1

Smoke density acc. to EN 50268 / IEC 61034

Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

Flame test : flame-retardant acc. to EN 50265-2-1, IEC 60332.1

CABLE PARAMETER

AWG | No. Of Cores × Nominal Cross Sectional Area | Nominal Thickness Of Insulation | Nominal Overall Diameter | Nominal Copper Weight | Nominal Weight | Minimum Insulation Resistance At 90 °C |

|---|---|---|---|---|---|---|

# × mm² | mm | mm | kg/km | kg/km | mΩ·km | |

H05Z-U | ||||||

20 | 0.6 | 1.9-2.4 | 4.8 | 8 | 0.015 | |

18 | 0.6 | 2.1-2.6 | 7.2 | 12 | 0.012 | |

17 | 0.6 | 2.2-2.8 | 9.6 | 14 | 0.011 | |

H07Z-U | ||||||

16 | 0.7 | 2.6-3.3 | 14.4 | 20 | 0.011 | |

14 | 0.8 | 3.2-4.0 | 24 | 30 | 0.010 | |

12 | 0.8 | 3.6-4.6 | 38 | 45 | 0.0085 | |

10 | 0.8 | 4.1-5.2 | 58 | 65 | 0.0070 | |

8 | 1.0 | 5.3-6.6 | 96 | 105 | 0.0070 | |

Introduction

In an era where electrical safety and environmental responsibility are paramount, the choice of wiring can make all the difference between a secure installation and a potential hazard. But what makes H05Z-U and H07Z-U cables stand out in the crowded field of electrical conductors? These cables, compliant with BS 7211 standards, are engineered for internal wiring in switchboards and distributor boards, offering robust performance in demanding environments. With alternating nominal voltages up to 1000 volts or direct voltages up to 750 volts, they are particularly suited for areas where fire risks could endanger lives and equipment, such as public and government buildings.

Understanding the Construction of H05Z-U and H07Z-U Cables

At the heart of any reliable cable is its construction, and H05Z-U and H07Z-U cables exemplify precision engineering. These cables feature a solid bare copper conductor, adhering to IEC 60228 Class 1 standards for single-wire design. This choice of material ensures excellent conductivity and durability, minimising resistance and heat buildup during operation.

The core insulation is made from cross-linked polyolefin EI5, a material renowned for its thermal stability and electrical insulation properties. This insulation is complemented by an LSOH sheath, which stands for low smoke zero halogen. Unlike traditional PVC cables that release toxic halogen gases and dense smoke when burned, LSOH materials produce minimal smoke and no corrosive gases, making them ideal for enclosed spaces.

Insulation colours are standardised for easy identification: green/yellow for earth, black, blue, brown, red, white, yellow, grey, and violet for other phases. This colour coding aligns with international norms, facilitating safe and efficient installations.

From a materials science perspective, the cross-linking process in the polyolefin insulation enhances molecular bonds, improving resistance to heat, chemicals, and mechanical stress. This results in a cable that can withstand operating temperatures up to 90°C, with short-circuit tolerance reaching 250°C. Such properties are crucial in high-load scenarios, where thermal degradation could otherwise compromise integrity.

Applications and Installation Considerations

H05Z-U and H07Z-U cables are primarily designed for fixed installations in pipes, ducts, or within appliances. Their voltage ratings—300/500V for H05Z-U and 450/750V for H07Z-U—cater to a range of low to medium voltage needs. In South African contexts, these cables are often deployed in public infrastructure, such as hospitals, schools, and office buildings, where compliance with SANS (South African National Standards) equivalents to BS 7211 is mandatory.

Installation guidelines emphasise flexibility and bending radii: a flexing radius of 15 times the overall diameter (Ø) and a static radius of 10 times Ø. This allows for routing in tight spaces without risking insulation damage. Operating temperatures range from +5°C to +90°C during flexing, ensuring reliability in varied climates, from the humid coastal regions of Durban to the arid interiors of the Northern Cape.

From an engineering viewpoint, these cables' design minimises electromagnetic interference, making them suitable for environments with sensitive electronic equipment. In distributor boards, their solid copper core provides low impedance paths, enhancing system efficiency and reducing energy losses.

However, installers must consider environmental factors. In areas prone to moisture or chemical exposure, additional protective conduits may be necessary, as the LSOH sheath, while flame-retardant, is not inherently waterproof.

Safety and Environmental Perspectives

Safety is the cornerstone of H05Z-U and H07Z-U cables. Their LSOH composition addresses the dual threats of fire propagation and toxic emissions. In a fire scenario, low smoke output improves visibility for evacuation, while zero halogen prevents acid formation that could damage firefighting equipment or building structures.

From an environmental science lens, these cables support sustainability goals. Halogen-free materials reduce long-term ecological impact, as they do not contribute to ozone depletion or persistent pollutants. In South Africa, where environmental regulations under the National Environmental Management Act are stringent, adopting LSOH cables aids compliance and promotes green building certifications like those from the Green Building Council of South Africa.

Comparatively, PVC cables, while cheaper, fail in fire safety tests, often leading to higher insurance premiums and retrofit costs. H05Z-U and H07Z-U, though premium, offer lifecycle savings through durability and reduced maintenance.

A risk assessment perspective highlights their role in mitigating arc faults and short circuits. The high short-circuit temperature tolerance (250°C) provides a buffer, allowing protective devices like circuit breakers to activate before catastrophic failure.

Performance Analysis and Comparisons

Performance-wise, these cables excel in insulation integrity and mechanical strength. The cross-linked polyolefin resists ageing, with a lifespan often exceeding 30 years under normal conditions. Benchmarked against similar products, such as harmonised European H07V-U cables, H05Z-U and H07Z-U offer superior fire performance due to LSOH.

In thermal dynamics, the insulation's high melting point prevents softening at elevated temperatures, maintaining dielectric strength. Electrical engineers value this for stable voltage drop calculations, ensuring efficient power delivery.

From a cost-benefit analysis, initial investment in these cables is offset by lower failure rates. In high-occupancy buildings, the peace of mind from reduced fire risks is invaluable.

Comparisons with armoured cables show that while H05Z-U/H07Z-U lack mechanical protection, their lightweight design (e.g., 105 kg/km for 10 mm²) makes them easier to handle, reducing labour costs.

H05Z-U and H07Z-U cables represent a pinnacle of safe, efficient electrical wiring under BS 7211 standards. Their LSOH design, solid copper construction, and rigorous technical specifications make them indispensable for modern installations, particularly in fire-prone environments. From safety enhancements to environmental benefits, these cables offer multifaceted advantages that justify their adoption.

As South Africa advances towards sustainable infrastructure, embracing such innovations ensures resilience and compliance. Whether you're an engineer, installer, or building owner, understanding these cables empowers better decisions. In the quest for electrical excellence, are H05Z-U and H07Z-U the ultimate solution? The evidence suggests yes.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430