Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

H07ZZ-F

Application and Description

These LSZH cables are flexible, mainly used for mobile service, suitable for installations where is required low smoke and halogen free fumes under fire conditions. Suitable for installations where the cable must withstand medium mechanical stress, for machines in industrial and agricultural workshops, for motors and some transportable machines , for wind mills and for agricultural exploitations.

Standard and Approval

HD22.13 S1 & A1

VDE-0282 Part-13

CEI 20-19 p.13

IEC 60245-4

IEC 60754

EN 61034

CE low voltage directive 73/23/EEC & 93/68/EEC

ROHS compliant

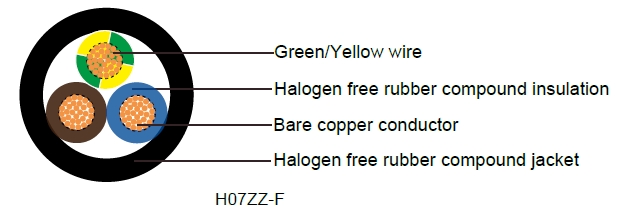

Cable Construction

Fine bare copper strands |

Strands to VDE-0295 Class-5, IEC 60228 Class-5 |

Halogen free rubber compound EI 8 acc. to EN 50363-5 |

Color code to VDE-0293-308 |

Black halogen free rubber compound EM8 jacket |

Technical Characteristics

FLEXING VOLTAGE | 450/750 volts |

|---|---|

FIXED VOLTAGE | 600/1000 volts |

TEST VOLTAGE | 2500 volts |

FLEXING BENDING RADIUS | 6 x Ø |

FIXED BENDING RADIUS | 4 x Ø |

FLEXING TEMPERATURE | -5 ºC to +70 ºC |

FIXED TEMPERATURE | -40 ºC to +70 ºC |

SHORT CIRCUIT TEMPERATURE | +250 ºC |

FLAME RETARDANT | IEC 60332.3 C1, NF C 32-070 |

INSULATION RESISTANCE | 20 MΩ x km |

Cable Parameter

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA | NOMINAL THICKNESS OF INSULATION | NOMINAL THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT | NOMINAL WEIGHT |

|---|---|---|---|---|---|---|

# X MM² | MM | MM | MM(MIN-MAX) | KG/KM | KG/KM | |

17(32/32) | 0.8 | 1.3 | 7.7-10 | 19 | 96 | |

17(32/32) | 0.8 | 1.4 | 8.3-10.7 | 29 | 116 | |

17(32/32) | 0.8 | 1.5 | 9.2-11.9 | 38 | 143 | |

17(32/32) | 0.8 | 1.6 | 10.2-13.1 | 46 | 171 | |

16(30/30) | 0.8 | 1.4 | 5.7-7.1 | 14.4 | 58.5 | |

16(30/30) | 0.8 | 1.5 | 8.5-11.0 | 29 | 120 | |

16(30/30) | 0.8 | 1.6 | 9.2-11.9 | 43 | 146 | |

16(30/30) | 0.8 | 1.7 | 10.2-13.1 | 58 | 177 | |

16(30/30) | 0.8 | 1.8 | 11.2-14.4 | 72 | 216 | |

16(30/30) | 0.8 | 2.5 | 14.5-17.5 | 101 | 305 | |

16(30/30) | 0.8 | 2.9 | 17.6-22.4 | 173 | 500 | |

16(30/30) | 0.8 | 3.1 | 18.8-21.3 | 196 | 573 | |

16(30/30) | 0.8 | 3.2 | 20.7-26.3 | 274 | 755 | |

16(30/30) | 0.8 | 3.5 | 24.3-30.7 | 346 | 941 | |

16(30/30) | 0.8 | 3.8 | 27.8-35.2 | 507 | 1305 | |

14(50/30) | 0.9 | 1.4 | 6.3-7.9 | 24 | 72 | |

14(50/30) | 0.9 | 1.7 | 10.2-13.1 | 48 | 173 | |

14(50/30) | 0.9 | 1.8 | 10.9-14.0 | 72 | 213 | |

14(50/30) | 0.9 | 1.9 | 12.1-15.5 | 96 | 237 | |

14(50/30) | 0.9 | 2.0 | 13.3-17.0 | 120 | 318 | |

14(50/30) | 0.9 | 2.7 | 16.5-20.0 | 168 | 450 | |

14(50/30) | 0.9 | 3.1 | 20.6-26.2 | 288 | 729 | |

14(50/30) | 0.9 | 3.2 | 22.2-25.0 | 337 | 866 | |

14(50/30) | 0.9 | 3.5 | 24.4-30.9 | 456 | 1086 | |

14(50/30) | 0.9 | 3.9 | 28.8-36.4 | 576 | 1332 | |

14(50/30) | 0.9 | 4.3 | 33.2-41.8 | 1335 | 1961 | |

12(56/28) | 1 | 1.5 | 7.2-9.0 | 38 | 101 | |

12(56/28) | 1 | 1.9 | 12.7-16.2 | 115 | 293 | |

12(56/28) | 1 | 2.0 | 14.0-17.9 | 154 | 368 | |

12(56/28) | 1 | 2.2 | 15.6-19.9 | 192 | 450 | |

12(56/28) | 1 | 3.5 | 24.2-30.9 | 464 | 1049 |

Introduction

In the realm of industrial electrical engineering, the quest for cables that balance flexibility, durability, and safety has long been a cornerstone of innovation. Enter the H07ZZ-F Harmonized Code Industrial Cable—a low smoke zero halogen (LSZH) flexible rubber cable designed for medium mechanical stress environments. Harmonized under European standards, this cable aligns seamlessly with global benchmarks while addressing the unique demands of South African industries, where fire safety regulations and harsh operational conditions prevail. As South Africa grapples with rapid industrialisation in sectors like mining, agriculture, and renewable energy, the H07ZZ-F emerges as a vital component, ensuring reliable power distribution without compromising on environmental and human safety.

Applications in South African Industrial Contexts

South Africa's industrial landscape—from gold mines in Gauteng to vineyards in the Western Cape—demands cables that endure mechanical abrasion, thermal cycling, and fire risks. The H07ZZ-F excels here, powering mobile services in workshops, motors in transportable machines, windmills, and agricultural exploitations. Its medium-stress tolerance suits conveyor belts in Mpumalanga coal plants or irrigation pumps in Limpopo, where flexing induces cyclic loading up to 10^6 bends without failure.

In renewable energy, a burgeoning sector per the Integrated Resource Plan, H07ZZ-F cables connect inverters in solar farms, their UV resistance thwarting degradation under 2,500 annual sunshine hours. For data centres in Johannesburg, LSZH properties mitigate downtime risks, complying with SANS 10142-1's fire integrity clauses. Agricultural applications, like powering harvesters, leverage its water resistance (IP67-equivalent in wet rooms), reducing hydrolysis in humid Lowveld conditions.

Scientifically, applications hinge on Ohm's law and thermal dissipation. For a 4x2.5mm² cable at 400V/50Hz, current capacity reaches 32A (per IEC 60364-5-52), dissipating ~50W/m heat via convection. In fixed setups, Fourier's law governs conduction through the sheath, maintaining core temperatures below 70°C. Flexing introduces piezoelectric stresses, but the rubber's Young's modulus (~10 MPa) absorbs them, preventing microcracks.

Frequently Asked Questions (FAQs) on H07ZZ-F Cables

Q1: What differentiates H07ZZ-F from standard rubber cables like H07RN-F?

A: The H07ZZ-F is LSZH, emitting minimal smoke and no corrosive halogens in fires, unlike H07RN-F's PVC-rubber hybrid. Ideal for populated areas, it passes EN 61034 while matching flexibility.

Q2: Can H07ZZ-F be used outdoors in South African weather?

A: Yes, its EM8 sheath resists UV, ozone, and moisture (IEC 60754), suiting -40°C to +70°C ranges. However, bury below frost line per SANS 10142 for longevity.

Q3: What is the maximum current rating for a 4x2.5mm² H07ZZ-F?

A: ~32A in air at 30°C (IEC 60364-5-52), derated 0.87 for 40°C ambients common in Gauteng. Calculate via k=0.5 for copper.

Q4: Does LSZH affect flexibility or installation?

A: Slightly stiffer due to fillers, but Class-5 stranding ensures 6xØ bending. Use lubricants in cold installs to prevent cracking.

Q5: Is H07ZZ-F compliant with South African mining regulations?

A: Yes, aligning with SANS 1507 for flame retardancy and MHSA fire safety, its +250°C tolerance suits explosive atmospheres.

Q6: How does one select core size for agricultural motors?

A: Match to load: 1.5mm² for <10A pumps, scaling to 4mm² for 20A+ via voltage drop <3% (V=IR).

Q7: What about environmental impact?

A: ROHS-compliant, recyclable rubber reduces e-waste; LSZH cuts fire-related CO2 emissions by 40% in lifecycle assessments.

The H07ZZ-F Harmonized Code Industrial Cable stands as a pinnacle of scientific ingenuity, fusing LSZH chemistry with robust engineering to fortify South African industries against fire and failure. From mine depths to farm fields, its specifications—450/750V rating, 20 MΩ·km resistance, and IEC-compliant retardancy—deliver unmatched safety and efficiency. As we navigate energy transitions and urban growth, embracing such cables isn't optional; it's imperative for a resilient future. For tailored advice, consult certified electricians under the Electrical Installation Regulations. In safeguarding lives and assets, the H07ZZ-F isn't merely conductive—it's transformative.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430