Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

ICEA SINGLE CORE CABLES MV90

ICEA Single Core Cables MV90: Designed for Efficient Medium Voltage Power Distribution from 5kV to 46kV, Featuring Robust Construction and Versatile Shielding Options

ICEA SINGLE CORE CABLES MV90

Description

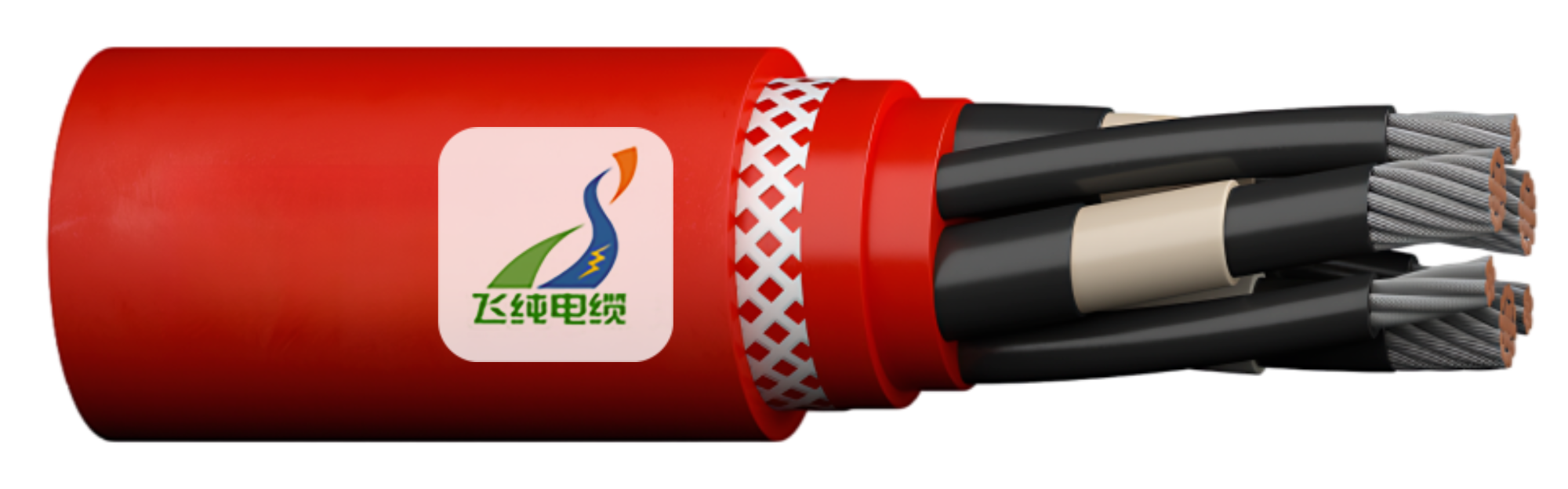

The single core cables are designed for distribution of electrical power with nominal voltage Uo/U ranging from 5KV to 46KV and frequency 50Hz. Single core cables are made of stranded copper or aluminium conductor, triple extruding insulating system consisting of thermosetting semi-conducting conductor shield, XLPE/TR-XLPE/EPR insulation and thermosetting semiconducting insulation shield. There are a number of designs of metallic shields including the copper tape helically applied with overlap, copper wire shield, concentric neutral, longitudinally applied corrugated copper tape and metal sheath available, which are surrounded with fillers and grounding conductor, overall binder tape and overall PVC, LSZH or PE jacket.

Standards

National Fire Protection Standard (NEPA 70): National Electric Code

AEIC CS8

ICEA S-93-639 (NEMA WC74), Standard for shielded power cable 5KV-46KV

ICEA S-97-682

IEEE 1202 – Flame Testing of cables for use in cable tray

ICEA T29-520 Vertical

UL 1072 for medium voltage cables.

Construction

Conductor: The conductor consists of uncoated Class B compressed concentric stranded aluminium alloy 1350 or soft drawn annealed copper meeting the requirement of ASTM B3. Unless otherwise specified, the conductor shall be supplied class B as per ASTM B496.

Conductor Shield

Conductor shield consists of extruded thermosetting semi conducting compound which is free stripping from conductor and bonded to the insulation.

Insulation

The insulation is either XLPE or EPR extruded concentrically over the conductor. High dielectric strength tree retardant XLPE (TR-XLPE) can be offered as option to provide an optimum balance of mechanical and electrical properties, insuring resistance to treeing.

100% or 133% insulation level is available upon request. The insulation meets or exceeds electrical and physical requirements of ICEA S-96-659/NEMA WC71, and UL 1072.

Insulation Shield

Insulation shield consists of extruded thermosetting semi-conducting compound with controlled adhesion to the insulation, providing required balance between electrical integrity and ease of stripping.

Metallic Shielding

1) Copper Tape

For Copper tape shield, helically bare 5 mil copper tape shield over the insulation shield with minimum overlap of 20%. There are grounding conductor made of bare stranded copper conductor per each interstices, per UL, ICEA and AST

2) Wire Shield

Bare copper wire shield is evenly spaced with 5000 circular mils minimum per inch of core diameter. The shield insures a reliable shield that can be easily terminated.

3) Concentric Neutral

Either bare or tinned copper wire (#6 to #9AWG) is helically applied around the cores.

Assembly

Cables are cabled together with a left hand lay and suitable filler to make the cable round. A binder tape is applied to maintain core geometry and mechanical stability. Fillers may be PP yarn, ramie yarn, plastics or other filler material.

Armour (optional)

For armouring options, inner PVC jacket is applied over the binder type. Corrugated aluminium interlocking armour (AIA) is applied over the inner jacket.

Jacket

A protective sunlight and ozone resistant jacket of PVC is extruded for a tight fit over the welded armour or the core assembly.

Options

-TR-XLPE insulation.

-Compact stranded conductor.

-Super smooth conductor shield.

-Zero or one grounding conductor.

-CPE, LLLPE, LSOH or low temperature PVC jacket.

-Oil resistant jacket.

What Are ICEA Single Core Cables MV90?

ICEA Single Core Cables MV90 are specialized electrical cables designed for medium voltage power distribution, capable of handling voltages between 5kV and 46kV. Unlike multi-core cables, these single-core designs focus on delivering power through a single conductor, making them ideal for applications requiring high reliability and minimal interference. Their construction includes a stranded copper or aluminum conductor, a triple-extruded insulating system, and various metallic shielding options, all encased in a protective outer jacket.

The Insulated Cable Engineers Association (ICEA) sets rigorous standards for these cables, ensuring they meet the demands of modern electrical systems. Certified under standards like ICEA S-93-639, ICEA S-97-682, and UL 1072, these cables are built to withstand harsh environmental conditions, resist electrical faults, and ensure long-term performance. Their versatility makes them suitable for a wide range of applications, from underground power distribution to industrial installations and renewable energy projects.

Standards and Certifications: Ensuring Quality and Safety

ICEA Single Core Cables MV90 adhere to stringent industry standards, ensuring they meet the highest benchmarks for performance and safety:

National Fire Protection Standard (NFPA 70): Compliance with the National Electric Code ensures safe installation and operation.

AEIC CS8: Specifies requirements for extruded dielectric shielded power cables.

ICEA S-93-639 (NEMA WC74): Covers shielded power cables rated 5kV to 46kV.

ICEA S-97-682: Addresses utility-shielded power cables.

IEEE 1202: Ensures flame resistance for cables used in cable trays.

ICEA T29-520: Verifies vertical flame performance.

UL 1072: Certifies the cables for medium voltage applications.

Applications: Powering Diverse Industries

The versatility of ICEA Single Core Cables MV90 makes them suitable for a wide range of applications:

Utility Power Distribution: Used in underground and overhead systems to deliver electricity to residential, commercial, and industrial areas.

Industrial Facilities: Powers heavy machinery, manufacturing plants, and data centers, where reliability is critical.

Renewable Energy: Connects wind turbines, solar farms, and energy storage systems to the grid, supporting the transition to clean energy.

Infrastructure Projects: Employed in transportation systems, such as railways and airports, where robust power delivery is essential.

Direct Burial and Cable Trays: Designed for harsh environments, including direct burial in soil or installation in cable trays, thanks to their durable construction and optional armoring.

Advantages of ICEA Single Core Cables MV90

The design and construction of these cables offer several advantages:

High Reliability: The triple-extruded insulation system and robust shielding ensure minimal risk of electrical faults.

Versatility: Multiple conductor, insulation, and shielding options allow customization for specific applications.

Durability: Resistant to environmental factors like sunlight, ozone, and moisture, with optional armoring for added protection.

Ease of Installation: Free-stripping conductor shields and controlled adhesion insulation shields simplify termination and splicing.

Safety: Compliance with rigorous standards ensures safe operation in demanding conditions.

Challenges and Considerations

While ICEA Single Core Cables MV90 are highly advanced, certain considerations must be addressed:

Cost: Copper conductors and specialized insulation like TR-XLPE can increase costs, requiring a balance between performance and budget.

Installation Expertise: Proper handling and termination require skilled technicians to ensure optimal performance.

Environmental Impact: While LSZH jackets reduce emissions in fire scenarios, the production and disposal of cables must be managed responsibly to minimize environmental impact.

Conclusion

ICEA Single Core Cables MV90 are a testament to the advancements in cable technology, offering a robust, reliable, and versatile solution for medium voltage power distribution. From their meticulously engineered construction to their compliance with rigorous industry standards, these cables are built to power the modern world. Whether supporting urban infrastructure, industrial operations, or renewable energy initiatives, they play a critical role in ensuring the seamless flow of electricity.

As technology continues to evolve, the ICEA Single Core Cables MV90 will remain at the forefront, adapting to new challenges and opportunities in the energy sector. For engineers, utilities, and industries, these cables are not just a component but a cornerstone of reliable power delivery, paving the way for a brighter, more connected future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430