Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

M(StD)HOEU: Low Voltage Screened Flat Cable for Festoon Application

M(StD)HOEU Low Voltage Screened Flat Cable: Designed Specifically for Demanding Festoon Applications

M(StD)HOEU Low Voltage Screened Flat Cable for Festoon Application

What is the M(StD)HOEU Low Voltage Screened Flat Cable?

The M(StD)HOEU is a specialized low voltage screened flat cable tailored for festoon applications, where cables are suspended in loops to accommodate the back-and-forth motion of machinery. "Festoon" refers to the way these cables are arranged—like decorative garlands—allowing them to extend and retract without tangling or excessive wear. This design is crucial for environments requiring severe bending in one plane, such as overhead cranes or conveyor systems.

What sets the M(StD)HOEU apart is its screened construction, which includes individual or overall shielding to protect against electromagnetic interference (EMI). This screening—typically an ALU/PETP foil with tinned copper wire spinning—ensures signal integrity for control cables and reliable power delivery, even in noisy industrial settings. The "low voltage" aspect refers to its rated voltage of 0.6/1 kV, making it ideal for applications below high-voltage thresholds but demanding robustness.

Produced under stringent standards like DIN VDE 0250-809, this cable combines flexibility with durability. Its flat profile minimizes space usage and reduces wind resistance in outdoor setups, while the polychloroprene outer sheath provides resistance to oils, chemicals, and weather. In essence, it's engineered for "medium mechanical stresses," meaning it handles dynamic movements without compromising performance, all while operating in dry, damp, wet, or outdoor conditions.

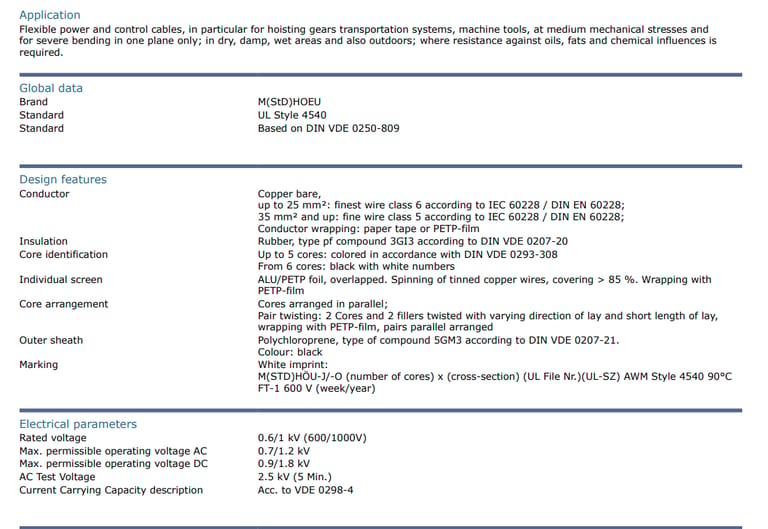

Technical Specifications: A Closer Look

To truly appreciate the M(StD)HOEU low voltage screened flat cable, we must dissect its technical DNA. Let's break it down into design features, electrical, thermal, and mechanical parameters, supported by data on various configurations.

Design Features

The cable's conductors are made of bare copper, with finer stranding for enhanced flexibility: finest wire class 6 (up to 25 mm²) or class 5 (35 mm² and above) per IEC 60228. This stranding allows the cable to bend repeatedly without fatigue. Each conductor is wrapped in paper tape or PETP-film for added protection, then insulated with a rubber compound (3GI3 type) known for its elasticity and resistance to environmental stressors.

Core identification is straightforward: colored for up to five cores (per DIN VDE 0293-308) or black with white numbers for more. The screening is a standout feature—ALU/PETP foil overlapped with tinned copper wires (covering >85%) and a PETP-film wrap—to shield against interference. Cores are arranged in parallel, with pairs twisted for control variants to minimize crosstalk.

The outer sheath, a black polychloroprene (5GM3 type), offers superior abrasion resistance and UV stability. Marking includes details like core count, cross-section, UL file number, and production week/year, ensuring traceability.

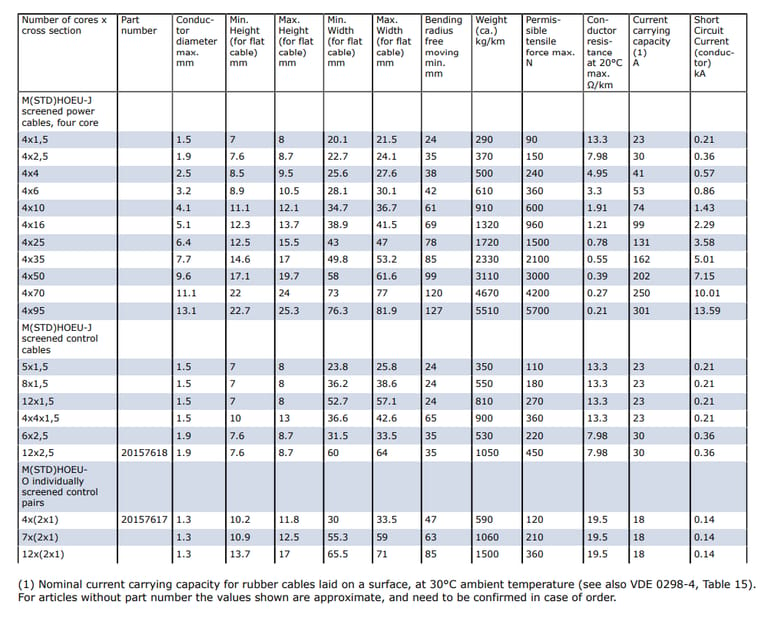

For control cables, variants include individually screened pairs (M(StD)HOEU-O) or overall screened (M(StD)HOEU-J), catering to power or signal needs.

Electrical Parameters

Rated at 0.6/1 kV, the cable supports max AC operating voltage of 0.7/1.2 kV and DC of 0.9/1.8 kV. It withstands a 2.5 kV AC test voltage for 5 minutes, proving insulation integrity. Current carrying capacity follows VDE 0298-4, varying by configuration—for instance, a 4x1.5 mm² power cable handles 23 A nominally.

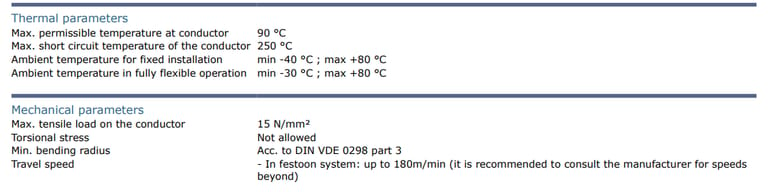

Thermal Parameters

Conductor temperature maxes at 90°C in operation, with short-circuit tolerance up to 250°C. Ambient ranges are impressive: -40°C to +80°C for fixed installs, -30°C to +80°C for flexible use, making it suitable for South Africa's varied climates, from arid mines to humid ports.

Mechanical Parameters

Tensile load caps at 15 N/mm² per conductor, with no torsional stress allowed—emphasizing one-plane bending. Minimum bending radius adheres to DIN VDE 0298 part 3, and travel speeds reach 180 m/min in festoon systems (consult manufacturer for higher). This enables high-speed operations in dynamic setups.

Usage Scenarios: Where It Shines

The M(StD)HOEU low voltage screened flat cable excels in festoon applications for hoisting gears, transportation systems, and machine tools. In cranes, it powers trolley movements while bending smoothly in one plane. For conveyor belts in factories or mines, it supplies control signals amid oil and chemical exposure.

Outdoors, its weather-resistant sheath suits port cranes handling containers, where wind and salt are factors. In machine tools, screened variants ensure precise data transmission without EMI from nearby motors. Speeds up to 180 m/min make it ideal for high-throughput logistics.

In South Africa, with its booming mining and ports, this cable addresses needs for reliable, flexible power in harsh conditions—resisting fats in food processing or chemicals in refineries.

Frequently Asked Questions

Q: What's the difference between power and control variants? A: Power (e.g., 4x cores) focuses on high current; control (e.g., 12x1.5) emphasizes screened signals for precision.

Q: Can it handle extreme cold? A: Yes, down to -30°C in flexible operation, ideal for South African winters.

Q: Is torsional twisting allowed? A: No—strictly one-plane bending to prevent damage.

Q: How does screening help? A: It blocks EMI, ensuring reliable performance in industrial noise.

Q: Suitable for speeds above 180 m/min? A: Consult manufacturer; standard limit is 180 m/min.

Conclusion

The M(StD)HOEU low voltage screened flat cable represents a pinnacle of flexible power and control technology for festoon applications. Its robust specs, versatile uses, and relevance to South Africa's challenges—from mining theft to port efficiency—make it indispensable. As industries evolve, embracing such innovations ensures resilience and progress. For engineers and enthusiasts alike, this cable isn't just wiring; it's the thread weaving industrial success.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430