Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Multi-core 600/1000V cables with stranded copper conductors

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

CONSTRUCTION

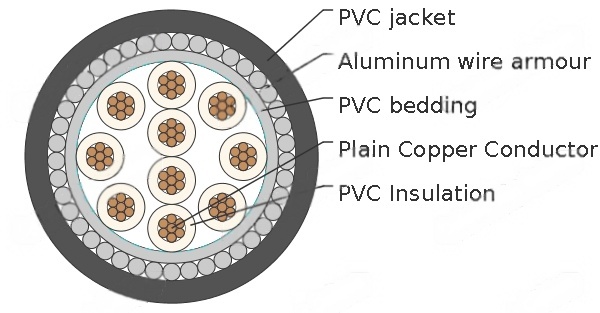

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

No. of Cores | Nominal cross-sectional area | Number/ wire | Nominal insulation thickness | Nominal bedding thickness | Nominal alum wire armor dia. | Nominal sheath thick ness | Approx. overall diameter | Approx. cable weight |

|---|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/mm | |

1.5 | 7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 15.2 | 500 | |

1.5 | 7/0.53 | 0.6 | 0.8 | 1.25 | 1.5 | 18.6 | 780 | |

1.5 | 7/0.53 | 0.6 | 0.8 | 1.25 | 1.5 | 19.4 | 830 | |

1.5 | 7/0.53 | 0.6 | 0.8 | 1.25 | 1.6 | 22.2 | 1090 | |

1.5 | 7/0.53 | 0.6 | 1.0 | 1.6 | 1.7 | 26.7 | 1600 | |

1.5 | 7/0.53 | 0.6 | 1.0 | 1.6 | 1.8 | 29.2 | 1940 | |

1.5 | 7/0.53 | 0.6 | 1.0 | 1.6 | 1.9 | 32.9 | 2360 | |

2.5 | 7/0.67 | 0.7 | 0.8 | 1.25 | 1.5 | 18.0 | 750 | |

2.5 | 7/0.67 | 0.7 | 0.8 | 1.25 | 1.6 | 21.8 | 1000 | |

2.5 | 7/0.67 | 0.7 | 0.8 | 1.25 | 1.6 | 22.4 | 1080 | |

2.5 | 7/0.67 | 0.7 | 1.0 | 1.6 | 1.7 | 26.6 | 1640 | |

2.5 | 7/0.67 | 0.7 | 1.0 | 1.6 | 1.8 | 30.7 | 2110 | |

2.5 | 7/0.67 | 0.7 | 1.0 | 1.6 | 1.9 | 34.0 | 2600 | |

2.5 | 7/0.67 | 0.7 | 1.2 | 2.0 | 2.1 | 39.5 | 3520 | |

4 | 7/0.85 | 0.8 | 0.8 | 1.25 | 1.6 | 20.5 | 970 | |

4 | 7/0.85 | 0.8 | 1.0 | 1.6 | 1.7 | 26.1 | 1500 | |

4 | 7/0.85 | 0.8 | 1.0 | 1.6 | 1.7 | 26.8 | 1630 | |

4 | 7/0.85 | 0.8 | 1.0 | 1.6 | 1.8 | 30.5 | 2170 | |

4 | 7/0.85 | 0.8 | 1.2 | 2.0 | 2.0 | 37.1 | 3170 | |

4 | 7/0.85 | 0.8 | 1.2 | 2.0 | 2.1 | 40.8 | 3910 | |

4 | 7/0.85 | 0.8 | 1.2 | 2.0 | 2.2 | 46.0 | 4790 |

What Are Multi-Core 600/1000V Armoured Cables?

At their core, these cables are engineered for low-voltage electricity supply in installations up to 1000V. They excel in underground applications within industrial sectors where protection against chemicals and physical damage is paramount, such as refinery areas or chemical plants. Unlike standard wiring, multi-core versions bundle multiple conductors – ranging from 7 to 48 cores in common configurations – allowing for versatile power and control circuits in a single cable run. This design reduces installation complexity and enhances efficiency in space-constrained environments.

The "armoured" aspect refers to the protective layer of steel wires or tapes that shields the inner components from external threats. For multi-core cables, this is typically Steel Wire Armour (SWA), providing mechanical strength without compromising flexibility. The voltage rating of 600/1000V means they can handle phase-to-earth voltages up to 600V and phase-to-phase up to 1000V, making them ideal for fixed installations in power networks. In South Africa, these cables must comply with local standards like SANS 1507, which governs low-voltage PVC and XLPE insulated cables, including armoured types, ensuring they meet rigorous safety and performance criteria. This alignment with SANS 1507 is vital, as it promotes quality and conformity for cables used in fixed installations, often mirroring international benchmarks like BS 5467 for thermosetting insulated armoured cables.

Applications in South African Industries: Powering Progress

South Africa's economy thrives on mining, manufacturing, and energy sectors, where these cables shine. In mining, they facilitate reticulation and underground power supply, enduring vibrations and moisture in tunnels. For refineries and chemical plants, the chemical resistance of PVC and armour protects against corrosive spills. They're used for main power distribution in houses, commercial buildings, and fire detection systems, often directly buried thanks to their robustness.

Under SANS 1507, these cables support house connections and switchgear wiring, complying with NRCS regulations for safety. In photovoltaic systems or emergency lighting, fire-retardant variants ensure operation during crises. Their versatility extends to intrinsically safe systems in hazardous areas, like petrochemical plants in Secunda.

Tackling Common Cable Issues: Prevention and Solutions

No technology is infallible, and multi-core armoured cables face challenges. Insulation failure tops the list, often from overvoltage, overload, or environmental stress, leading to short circuits. Solutions include regular dielectric testing and using XLPE for better resistance.

Aging and degradation from UV exposure or heat can brittle sheaths; mitigate with UV-resistant outer layers and periodic inspections. Water ingress, especially in submerged installations, corrodes armour and insulators – avoid by sealing joints and using water-blocking fillers.

Fatigue in stranded conductors from vibrations causes breaks; stranded design helps, but secure routing minimises movement. Improper installation, like poor crimps or overbending, is a root cause of failures – adhere to bending radii and use certified installers. Electromagnetic interference in multi-cores can be addressed with proper shielding or balanced layouts.

In South Africa, substandard imports undermine standards; insist on SANS-compliant products to avoid these pitfalls. Maintenance involves visual checks, insulation resistance tests, and armour continuity verification.

Multi-core 600/1000V armoured cables with stranded copper conductors are more than components; they are the unsung heroes ensuring South Africa's industries operate safely and efficiently. Their blend of flexibility, durability, and compliance with standards like SANS 1507 makes them vital in facing the unique challenges of our environment. By understanding their construction, applications, and potential issues, we can better appreciate their role in powering the nation's future. As technology evolves, perhaps with smarter materials or integrated sensors, these cables will continue to adapt, keeping the lights on in even the toughest conditions.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430