Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Multi-core 600/1000V cables with stranded copper conductors

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

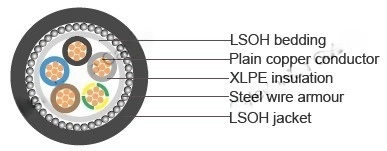

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal Bedding Thickness | Nominal Steel Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 15.2 | 500 | |

7/0.53 | 0.6 | 0.8 | 1.25 | 1.5 | 19.4 | 820 | |

7/0.53 | 0.6 | 0.8 | 1.25 | 1.6 | 22.2 | 1080 | |

7/0.53 | 0.6 | 1 | 1.6 | 1.7 | 26.7 | 1550 | |

7/0.53 | 0.6 | 1 | 1.6 | 1.7 | 29 | 1850 | |

7/0.53 | 0.6 | 1 | 1.6 | 1.8 | 32.7 | 2250 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 17.1 | 730 | |

7/0.67 | 0.7 | 0.8 | 1.25 | 1.6 | 22.4 | 1020 | |

7/0.67 | 0.7 | 1 | 1.6 | 1.7 | 26.6 | 1530 | |

7/0.67 | 0.7 | 1 | 1.6 | 1.8 | 30.7 | 1960 | |

7/0.67 | 0.7 | 1 | 1.6 | 1.8 | 33.8 | 2450 | |

7/0.67 | 0.7 | 1.2 | 2 | 2 | 39.3 | 3260 | |

7/0.85 | 0.7 | 0.8 | 1.25 | 1.5 | 19.7 | 840 | |

7/0.85 | 0.7 | 1 | 1.6 | 1.6 | 25.7 | 1390 | |

7/0.85 | 0.7 | 1 | 1.6 | 1.7 | 29.3 | 1850 | |

7/0.85 | 0.7 | 1 | 1.6 | 1.9 | 34.4 | 2350 | |

7/0.85 | 0.7 | 1.2 | 2 | 2 | 39.2 | 2800 | |

7/0.85 | 0.7 | 1.2 | 2 | 2.1 | 44.1 | 3250 |

The number of cores can be ordered upon request.

Introduction

In the bustling realm of electrical engineering and infrastructure development, cables form the unsung backbone of modern society. From powering homes and factories to controlling sophisticated machinery, the right cable can mean the difference between seamless operation and catastrophic failure. Among the myriad options available, multi-core 600/1000V armoured cables with stranded copper conductors stand out for their robustness, versatility, and adherence to stringent safety standards. These cables, often armoured with galvanised steel wire for multi-core configurations, are engineered to withstand harsh environments while ensuring reliable power and control transmission.

Applications: Versatility in Power and Control

Multi-core 600/1000V armoured cables with stranded copper conductors excel in diverse applications, particularly where reliability under duress is paramount. Their primary use is in power and control circuits, transmitting electricity and signals in industrial, commercial, and infrastructure projects.

In power distribution, these cables handle voltages up to 1000V, making them ideal for low-voltage systems in factories, mines, and renewable energy setups. For example, in South Africa's mining sector, where equipment operates in dusty, vibration-prone environments, the GSWA protects against mechanical damage, while the stranded conductors ensure flexibility for movable machinery like conveyor belts.

Control applications benefit from the multiple cores—ranging from 7 to 48 or more upon request—allowing simultaneous transmission of power and signals. In automated systems, such as those in Durban's port facilities, separate cores can carry control signals for motors, sensors, and PLCs without interference.

Outdoor and buried installations are another forte. The armour enables direct burial in soil, resisting moisture and pests, which is crucial for rural electrification projects under Eskom's initiatives. Inside buildings, they provide fire safety: the LSOH sheath and flame-retardant properties (BS EN 60332-1-2 and 60332-3-24) reduce risks in high-occupancy structures like shopping centres in Pretoria.

From an environmental perspective, these cables support sustainable practices. Their halogen-free design complies with global eco-standards, minimising environmental impact during manufacturing and disposal. In South Africa, where climate resilience is key, their temperature range (0°C to +90°C) suits varying conditions from the arid Karoo to humid coastal regions.

Economically, the cables' durability translates to lower maintenance costs. A 19-core 2.5 mm² cable, weighing about 1530 kg/km, might seem hefty, but its longevity in harsh setups justifies the investment, especially in export-oriented industries.

Why Choose These Cables?

These cables offer multifaceted benefits. Mechanically, GSWA provides crush resistance up to 5 kN/m, far superior to unarmoured variants, extending lifespan in industrial zones.

Electrically, stranded copper's flexibility reduces fatigue failures, with conductivity ensuring minimal energy loss—critical in energy-scarce South Africa.

Safety-wise, LSOH and low-smoke features protect lives, as seen in regulations post-tragic fires like the Grenfell Tower incident, influencing global standards.

Cost-effectively, though initial outlay is higher (due to copper and armour), total ownership cost drops via reduced downtime. Environmentally, recyclability of copper (up to 95%) supports circular economies.

Compared to PVC-sheathed cables, these excel in fire-prone areas; versus aluminium conductors, copper offers better ampacity (e.g., 1.5 mm² copper carries ~20A vs. aluminium's ~15A).

Installation benefits include ease of termination due to colour coding and stranding, though heavier weights demand proper handling equipment.

Frequently Asked Questions (FAQs)

What makes stranded copper conductors preferable in these cables? Stranded conductors offer superior flexibility and resistance to vibration, ideal for dynamic installations. Copper's high conductivity ensures efficient power transmission.

Can these cables be used in fire-hazardous areas? Yes, their LSOH sheath and flame-retardant properties make them suitable where smoke and toxins pose risks, complying with BS EN standards.

What's the difference between single-core and multi-core armour? Single-core uses aluminium wire armour (AWA) to avoid magnetic hysteresis losses, while multi-core employs GSWA for robust mechanical protection.

How do I select the right core count and size? Base it on load requirements: more cores for complex controls, larger cross-sections (e.g., 4 mm²) for higher currents. Consult parameters for weight and diameter.

Are these cables suitable for outdoor use in South Africa? Absolutely, with armour for burial and UV-resistant sheath, they withstand local weather extremes.

What maintenance do they require? Minimal: periodic visual inspections for damage, especially in buried setups. Avoid overloading to prevent overheating.

Conclusion

Multi-core 600/1000V armoured cables with stranded copper conductors embody engineering excellence, blending durability, safety, and efficiency. From their layered construction to versatile applications, they address the demands of modern electrical systems, particularly in South Africa's evolving infrastructure landscape. As we push towards sustainable energy and smarter grids, these cables will remain pivotal. For professionals and enthusiasts alike, understanding their nuances empowers better decisions, ensuring reliable power for generations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430