Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

N2XY IEC 60502-1 XLPE PVC 0.6/1kV Cable

Application | Used for electricity supply in low voltage installation systems. Suitable for underground use in industrial applications with additional mechanical protection. Can be fixed on cable trays, within conduits, or to walls. |

Voltage Rating | Uo/U: 0.6/1kV |

Temperature Rating | During installation: -5°C to +50°C |

Minimum Bending Radius | Fixed: 12 x overall diameter |

Conductor | RE: Class 1 solid copper conductor |

Insulation | XLPE (Cross-Linked Polyethylene) |

Bedding | PVC (Polyvinyl Chloride) |

Sheath | PVC (Polyvinyl Chloride) |

Core Identification | 3 core: Green/Yellow, Blue, Brown |

Sheath Colour | Black |

Standards | IEC 60502-1, VDE 0276-603, IEC/EN 60228 |

Construction of the N2XY Cable

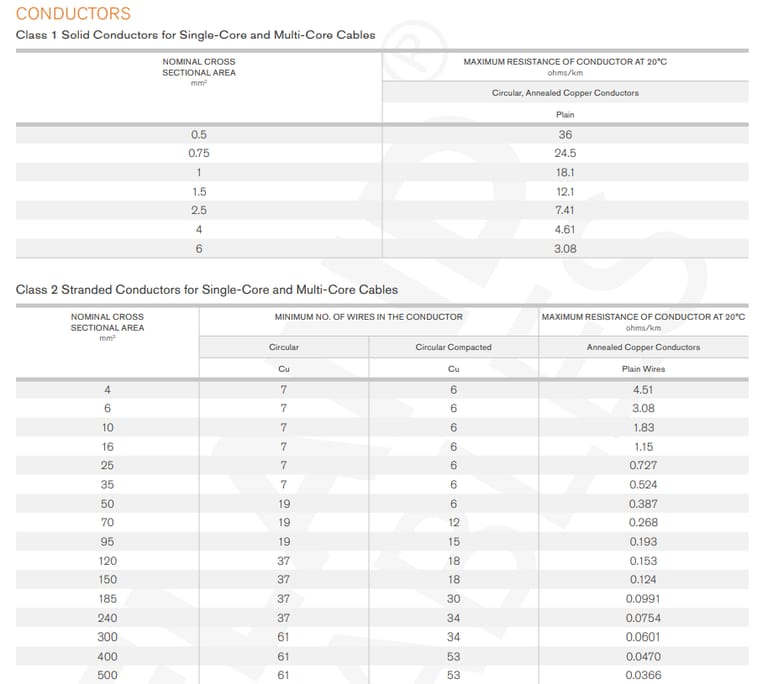

At its core—pun intended—the N2XY IEC 60502-1 XLPE PVC 0.6/1kV cable is a testament to layered engineering designed for the rigours of low-voltage environments. Let's start with the conductor, the cable's conductive heart. Available in three configurations under IEC/EN 60228 standards: RE (Class 1 solid copper conductor) for straightforward, vibration-free fixed installations; RM (Class 2 stranded circular or circular compacted) for flexibility in routing; and SM (Class 2 stranded sectoral shaped) for optimised space in multi-core setups. Copper's high conductivity—about 58 MS/m (mega-siemens per metre)—ensures minimal voltage drop, crucial in sprawling industrial sites where even a 1% loss can cascade into inefficiencies.

Encapsulating this conductor is the star of the show: XLPE (cross-linked polyethylene) insulation. Unlike traditional PVC (polyvinyl chloride) layers, which soften under heat and risk deformation, XLPE undergoes a chemical cross-linking process during extrusion, forming a thermoset polymer network. This grants it superior thermal stability up to 90°C in fixed installations, resisting cracking and electrical breakdown even under overloads. Imagine XLPE as a molecular chainmail: flexible yet unbreakable, preventing moisture ingress and partial discharges that plague lesser insulations. Studies show XLPE extends cable lifespan by 20-30% in humid, subtropical climates like South Africa's, where coastal corrosion is a perennial foe.

Next comes the bedding layer, another PVC compound that acts as a cushion, bedding the insulated cores snugly before the outer sheath. This inner PVC—formulated for low emission of corrosive gases—provides mechanical buffering against abrasion during pulling through conduits. The outermost sheath, also PVC, is black for UV resistance, ensuring longevity in direct burial or tray-mounted scenarios. Core identification follows a colour-coded logic straight from the standards: for a 3-core cable, green/yellow (earth), blue (neutral), and brown (phase); scaling up to 7+ cores with black insulation and white numbering for clarity in complex panels.

Flame retardancy seals the deal, meeting IEC/EN 60332-1-2 specs—no sustained flaming after a single vertical burn test. In a country where fire risks from faulty wiring contribute to urban blazes, this isn't optional; it's essential. The overall design—unarmoured for cost-effectiveness—tips the scales at 12 times the cable's outer diameter for minimum bending radius in fixed installs, allowing navigable bends in tight mine shafts or urban ducts without kinking the conductor.

This construction isn't arbitrary; it's a symphony of materials science tailored for 0.6/1kV (Uo/U) ratings, where Uo is the nominal voltage to earth and U is phase-to-phase. In South African terms, think of it powering the conveyor belts in Mpumalanga's coal mines or the irrigation pumps in the Free State's farmlands—quietly, reliably.

Performance Under Pressure: Key Characteristics and Standards Compliance

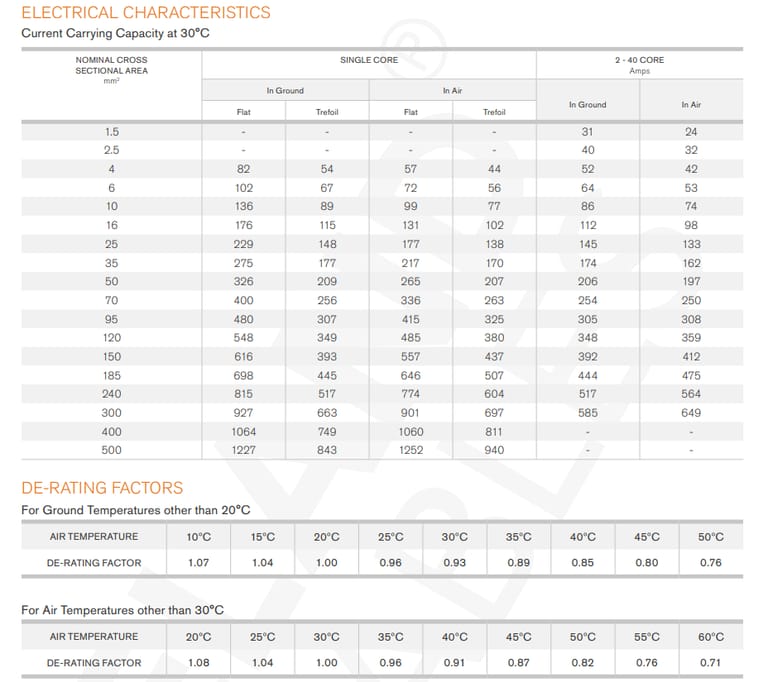

Diving deeper, the N2XY cable's characteristics read like a blueprint for endurance. Voltage rating at 0.6/1kV positions it perfectly for secondary distribution in low-voltage networks, handling the 230/400V three-phase systems standard in Eskom's grid. Temperature tolerances are battle-tested: installation from -5°C to +50°C accommodates Jozi's winter chills and Durban's summer sizzles, while operational range (-20°C to +90°C) shrugs off ambient extremes. Short-circuit withstand? Up to 250°C for five seconds, thanks to XLPE's low thermal resistivity (around 3.5 K·m/W).

Bending radius—12x overall diameter for fixed use—ensures installers can route without fatigue fractures, a nod to on-site practicality. But standards compliance elevates it: IEC 60502-1 governs power cables up to 30kV, with VDE 0276-603 adding European rigour on testing for dielectric strength. These aren't mere stamps; they mandate rigorous type tests like tan delta measurements (under 0.004 at 90°C) to detect insulation voids, ensuring the cable's capacitance remains stable over decades.

In South Africa, where the National Regulator of Complying with SANS 1507 (aligned with IEC 60502-1) is non-negotiable, the N2XY shines. Yet, as imports flood the market—cheap knockoffs from Asia lacking proper cross-linking—incidents of premature failures spike. A JSE-listed manufacturer recently warned that substandard XLPE PVC cables pose fire hazards in key sectors like mining and renewables, potentially costing jobs and lives. Opting for certified N2XY isn't snobbery; it's safeguarding against the 15% failure rate plaguing non-compliant imports.

Applications in South Africa's Diverse Terrain

The N2XY cable's versatility is its superpower, adapted for electricity supply in low-voltage installation systems. It's the go-to for fixed wiring in industrial applications, where underground burial demands mechanical protection via conduits or trays. Picture it snaking through Gauteng's factories, feeding 0.6/1kV to assembly lines, or buried in the Karoo's solar farms, linking inverters to the grid without armoured bulk.

In urban settings, it's fixed to walls or trays in high-rises, its PVC sheath warding off rodent nibbles—a real issue in Cape Town's informal settlements. For multi-core variants (up to 7+), it's ideal for auxiliary circuits in substations, with colour-coding slashing installation errors by 40%, per industry audits.

But let's ground this in 2025's realities. With Eskom's grid stabilising and eyes on green power, N2XY cables are pivotal in hybrid setups. Take the solar boom: households like Mark Moodley's in KZN, where a rooftop array kept his elderly mum's life-support running through blackouts, rely on these cables for DC-to-AC conversion. XLPE's low dielectric losses (under 0.5% at 50Hz) make it perfect for photovoltaic tie-ins, minimising energy waste in the Just Energy Transition Partnership's R152-billion push.

Underground use? In industrial zones, it's bundled with mechanical protection against the very theft syndicates plaguing the nation. Joburg's City Power recently disconnected thousands in an electricity theft crackdown, uncovering illegal splices that corrode standard cables—but N2XY's robust PVC bedding resists such tampering. In Primrose, Ekurhuleni, where cable theft hit "crisis levels," mayoral interventions highlight how upgrading to theft-resistant designs like N2XY could stem R1-billion annual losses.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430