Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

N3GHSSYCY Medium-Voltage Cable VDE 0250 Part 605

Why N3GHSSYCY Medium-Voltage Mining and Tunnelling Cables Are Essential for Safety, Reliability, and Performance in South African Heavy Industry

N3GHSSYCY Medium-Voltage Cable VDE 0250 Part 605

Applications | These cables are used for the connection of mobile operatingequipment, in mines and undergroundexcavations with hazardous environments,in stationary operation, e.g.high-voltage transformers in mining andtunnelling. |

Standards | VDE 0250 Part 605 |

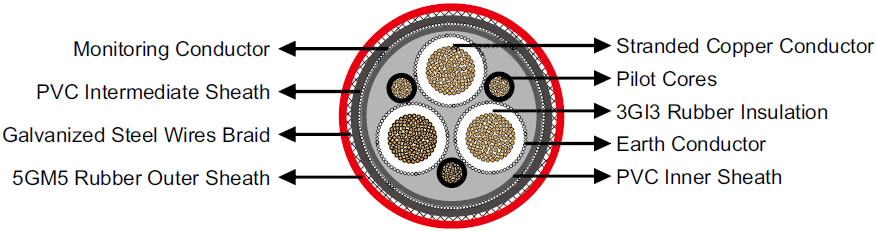

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Insulation | EPR compound type 3GI3. |

Electrical Field Control | Inner and outer semiconductive layer ofsemiconductive rubber, for 6 kV outersemiconductive layer only. |

Pilot Cores | Stranded copper conductor with EPR insulation. |

Earth Conductor | Spiral ofcopper wiresover the outer semi-conductivelayer of the cores. |

InnerSheath | PVC compound type YM5. |

Monitoring Conductor | Conductive tape serving and overallconcentric Cu wire spinning. |

Intermediate Sheath | PVCcompound type YM5. |

Armour | Braid of galvanized steel wires. |

Outer Sheath | PVC compound type YM5. |

Dimensions and Weight

3.6/6kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

3×25+3×16/3E+3×2.5ST+UEL | 49.0 | 53.0 | 4190 |

3×35+3×16/3E+3×2.5ST+UEL | 52.0 | 56.0 | 4800 |

3×50+3×25/3E+3×2.5ST+UEL | 55.0 | 59.0 | 5600 |

3×70+3×35/3E+3×2.5ST+UEL | 59.0 | 63.0 | 6650 |

3×95+3×50/3E+3×2.5ST+UEL | 63.0 | 67.0 | 7940 |

6/10kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

3×25+3×16/3E+3×2.5ST+UEL | 55.0. | 58.0 | 5300 |

3×35+3×16/3E+3×2.5ST+UEL | 58.0 | 61.0 | 5910 |

3×50+3×25/3E+3×2.5ST+UEL | 61.0 | 65.0 | 6790 |

3×70+3×35/3E+3×2.5ST+UEL | 65.0 | 69.0 | 7860 |

3×95+3×50/3E+3×2.5ST+UEL | 68.0 | 73.0 | 9180 |

8.7/15kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

3×25+3×16/3E+3×2.5ST+UEL | 58.0 | 62.0 | 6810 |

3×35+3×16/3E+3×2.5ST+UEL | 61.0 | 65.0 | 7850 |

3×50+3×25/3E+3×2.5ST+UEL | 64.7 | 68.7 | 9130 |

3×70+3×35/3E+3×2.5ST+UEL | 67.9 | 71.9 | 10750 |

3×95+3×50/3E+3×2.5ST+UEL | 72.4 | 76.4 | 12290 |

12/20kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

3×25+3×16/3E+3×2.5ST+UEL | 62.3 | 66.3 | 8790 |

3×35+3×16/3E+3×2.5ST+UEL | 65.3 | 69.3 | 9930 |

3×50+3×25/3E+3×2.5ST+UEL | 69.0 | 73.0 | 11360 |

3×70+3×35/3E+3×2.5ST+UEL | 72.2 | 76.2 | 13100 |

3×95+3×50/3E+3×2.5ST+UEL | 76.8 | 80.8 | 14750 |

Introduction

South Africa’s mining industry is one of the most advanced in the world, providing not only gold and platinum but also coal, manganese, and industrial minerals that power the global economy. Yet, mining operations—especially underground—face enormous technical challenges. One of the most critical factors in ensuring safe and reliable operation is the choice of power cables.

Among the cables that stand out in demanding applications is the N3GHSSYCY medium-voltage cable, a flexible, armored, and highly durable cable designed under VDE 0250 Part 605 standards. This type of cable is widely used for powering mobile equipment in mines and tunnelling projects, especially in hazardous and vibration-heavy environments

Benefits of N3GHSSYCY Cable

Safety in Hazardous Environments

Armoured protection against mechanical impact and rodents.

Semiconductive layers ensure reliable field control at medium voltage.

Built-in monitoring conductor allows early fault detection.

Reliability in Harsh Conditions

Resistant to moisture, chemicals, and oils common in mining.

Can operate safely in confined underground tunnels.

Designed to withstand repeated flexing and mechanical load.

Compliance with Standards

Manufactured according to VDE 0250 Part 605, ensuring international compliance.

Aligns with South African Bureau of Standards (SABS) expectations for imported cables used in mining.

Long Service Life

Robust design reduces downtime and maintenance costs.

Optimized for high mechanical and electrical endurance.

Installation and Maintenance Recommendations

Correct installation and ongoing maintenance are essential for maximizing performance and ensuring compliance with mining safety standards.

Installation Guidelines:

Ensure minimum bending radius is respected during cable laying.

Avoid sharp bends and excessive pulling tension during installation.

Use cable clamps and hangers designed for armored cables in vertical shafts.

Verify grounding connections are properly bonded for safety.

Maintenance Recommendations:

Regular insulation resistance testing to detect early degradation.

Check for mechanical wear in high-tension areas, especially near moving equipment.

Replace damaged outer sheathing promptly to prevent moisture ingress.

Use the built-in monitoring conductor for predictive maintenance.

By following these practices, South African mines can prevent unplanned outages and costly downtime, ensuring a higher level of safety compliance.

Application Scenarios

The N3GHSSYCY medium-voltage cable is widely used in:

Underground Mining: Supplying power to mobile drilling rigs, shuttle cars, and conveyor belts.

Tunnelling Projects: Powering tunnel boring machines (TBMs) and ventilation systems.

Stationary Installations: Connecting high-voltage transformers in mining and tunnelling stations.

Hazardous Environments: Suitable for areas with risks of gas, dust, or water exposure.

Case Study: South Africa’s Deep-Level Gold Mines

South Africa’s Witwatersrand gold basin, home to some of the deepest mines in the world, requires highly specialized electrical systems. In 2023, AngloGold Ashanti reported increased investments in cable safety upgrades to address electrical fault-related downtime.

The adoption of N3GHSSYCY cables was highlighted in underground conveyor systems, where mobile and stationary power needs coexist. Their armored design and monitoring conductors allowed for safer fault detection, preventing costly shutdowns and reducing fire hazards.

This aligns with broader trends in South Africa, where the Mine Health and Safety Act increasingly emphasizes electrical safety compliance in hazardous underground conditions.

Frequently Asked Questions (FAQ)

1. What voltage classes are available for N3GHSSYCY cables?

They are typically available in 3.6/6kV, 6/10kV, 8.7/15kV, and 12/20kV.

2. Are these cables suitable for use in South Africa’s mining sector?

Yes, they comply with VDE standards and can be used in South Africa when aligned with SANS and NRCS requirements.

3. Can N3GHSSYCY cables be used for flexible mobile equipment?

Yes, they are designed with stranded copper conductors and robust insulation to withstand frequent movement.

4. How do these cables improve safety in hazardous environments?

They have semiconductive layers for field control, armored protection, and monitoring conductors to detect faults early.

5. What is the typical service life of N3GHSSYCY cables?

When properly installed and maintained, service life can exceed 20 years in stationary operation, and several years in mobile mining equipment under harsh loads.

The N3GHSSYCY medium-voltage cable represents a critical component in South Africa’s mining and tunnelling industries, where electrical reliability directly affects productivity and worker safety.

With its robust construction, compliance with international standards, built-in monitoring capabilities, and proven track record in hazardous environments, the N3GHSSYCY cable is one of the most reliable solutions for powering both stationary and mobile mining equipment.

As South Africa continues to push the limits of deep-level mining and large tunnelling projects, the adoption of high-performance medium-voltage cables like N3GHSSYCY will remain central to achieving operational safety, efficiency, and compliance.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430