Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NSGAFOEU/NSHXAFOE Medium-Voltage Single Core Cables DIN VDE 0250 Part 602 /606

Understanding NSGAFOEU and NSHXAFOE Medium Voltage Single Core Cables

NSGAFOEU/NSHXAFOE Medium-Voltage Single Core Cables DIN VDE 0250 Part 602 /606

Applications | These cables are designed for fixed installation in track-bound vehicles and buses,in pipes and closed installation ducts, as well as for theconnection of mobile parts. 3 kV-rated cables can beused in low-voltage switch boards to ensure inherentlyshort-circuit and earth-fault proof connections. |

Standards | DIN VDE 0250 Part 602 (for NSGAFOEU/NSGAFCMOEU) |

Construction  | |

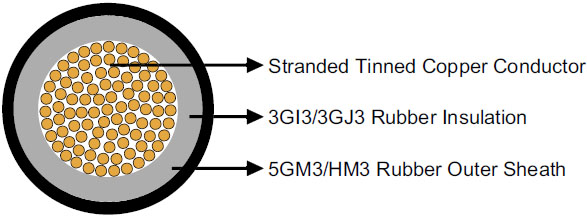

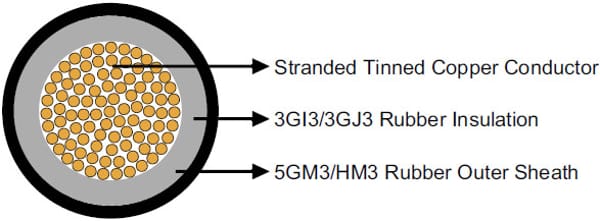

Conductors | Stranded tinned copper conductor, class 5 according to DIN VDE 0295/IEC 60228. |

Inner Conductor Layer (for 6kV) | Semi-conducting layer. |

Insulation | EPR compound type 3GI3/3GJ3. |

Optional Screen (for NSGAFCMOEU/NSHXAFCMOE) | Tinned copper wires. |

Outer Sheath | Chlorinated rubber type 5GM3, oil resistant and flame retardant (for NSGAFOEU/ NSGAFCMOEU). |

Dimensions and Weight

NSGAFOEU/NSHXAFOE 1.8/3kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

1×1.5 | 5.7 | 7.0 | 50 |

1×2.5 | 6.0 | 7.5 | 60 |

1×4 | 6.8 | 9.0 | 80 |

1×6 | 7.3 | 9.5 | 100 |

1×10 | 8.7 | 11.0 | 160 |

1×16 | 10.0 | 13.0 | 230 |

1×25 | 12.4 | 15.0 | 340 |

1×35 | 13.4 | 16.5 | 430 |

1×50 | 14.9 | 18.0 | 580 |

1×70 | 16.6 | 20.5 | 780 |

1×95 | 19.3 | 24.0 | 1030 |

1×120 | 20.8 | 26.0 | 1270 |

1×150 | 23.0 | 28.0 | 1570 |

1×185 | 25.2 | 31.0 | 1900 |

1×240 | 28.1 | 34.5 | 2500 |

1×300 | 30.8 | 38.0 | 3000 |

1×400 | 40.0 | 34.6 | 4000 |

NSGAFOEU/NSHXAFOE 3.6/6kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

1×1.5 | 8.3 | 9.5 | 135 |

1×2.5 | 8.6 | 10.5 | 150 |

1×4 | 9.4 | 12.0 | 170 |

1×6 | 9.9 | 13.0 | 200 |

1×10 | 10.9 | 14.5 | 250 |

1×16 | 12.6 | 15.5 | 350 |

1×25 | 14.5 | 17.5 | 480 |

1×35 | 15.6 | 19.0 | 600 |

1×50 | 17.1 | 21.0 | 760 |

1×70 | 18.8 | 23.0 | 960 |

1×95 | 21.3 | 26.5 | 1240 |

1×120 | 23.2 | 28.5 | 1530 |

1×150 | 25.0 | 30.5 | 1790 |

1×185 | 26.8 | 33.0 | 2130 |

NSGAFCMOEU/NSHXAFCMOE 3.6/6kV

Number of Cores×Nominal Cross Section | Nominal Overall Diameter | Nominal Weight |

No.×mm² | mm | kg/km |

1×185 | 38.5 | 3060 |

Why Medium Voltage Cables Matter in South Africa

South Africa’s mining and heavy industry sectors are heavily reliant on reliable electrical power distribution systems. Mines, processing plants, smelters, and heavy machinery require cables that can deliver medium voltage power efficiently, safely, and under extreme conditions. Among the specialized cables available, NSGAFOEU and NSHXAFOE medium voltage single core cables have emerged as trusted solutions due to their robust construction, high flexibility, flame resistance, and compliance with stringent international standards.

These cables are not only vital in fixed installations like switchboards and industrial power feeds but also in dynamic environments such as track-bound vehicles, conveyor systems, and mobile equipment connections. In South Africa, where the mining industry contributes more than 7% to the GDP and where heavy industry requires uninterrupted operations, the importance of selecting the right medium voltage cables cannot be overstated.

Cable Types: NSGAFOEU vs NSHXAFOE

Although both NSGAFOEU and NSHXAFOE cables belong to the medium voltage single core family, they differ mainly in sheath material and fire safety characteristics:

NSGAFOEU

Sheath: Chlorinated rubber (type 5GM3)

Features: Oil-resistant, flame-retardant

Best suited for environments where oil exposure and mechanical stress are prevalent.

NSHXAFOE

Sheath: Halogen-free polymer compound (HM3)

Features: Oil-resistant, flame-retardant, low smoke, halogen-free

Ideal for enclosed or populated environments where smoke toxicity during a fire is a concern.

Both versions are designed for medium voltage applications (up to 6kV) and comply with DIN VDE 0250 standards, ensuring international reliability and acceptance.

Standards Compliance

These cables are designed to meet strict international standards:

DIN VDE 0250 Part 602 (for NSGAFOEU/NSGAFCMOEU)

DIN VDE 0250 Part 606 (for halogen-free NSHXAFOE/NSHXAFCMOE)

In South Africa, while the SANS 1520-1 mining cable standards apply to local products, imported medium voltage cables like NSGAFOEU and NSHXAFOE are often used in specialized industrial projects where European compliance standards are accepted.

Application Scenarios in South Africa

1. Mining Sector

Used for medium voltage power supply in underground mines.

Withstands harsh mechanical stress, humidity, and exposure to oil-based drilling fluids.

Halogen-free versions minimize toxic smoke risks in case of underground fires.

2. Heavy Industry and Smelting

Power distribution in steel plants, refineries, and cement factories.

Resistance to oil, heat, and abrasion ensures longevity in production environments.

3. Railway and Transport

Fixed installations in track-bound vehicles and electric buses.

Suitable for switchboards and auxiliary power feeds.

4. Renewable Energy Projects

Applied in wind farms and solar PV installations where medium voltage distribution is essential.

Halogen-free sheath is preferred in eco-sensitive regions.

Benefits of NSGAFOEU/NSHXAFOE Cables

High flexibility → Easier installation in confined industrial spaces.

Resistance to oils, chemicals, and mechanical stress → Longer service life.

Flame-retardant and low smoke → Safer for underground and enclosed environments.

Compliance with international standards → Trusted across multiple industries.

Adaptability → Suitable for both fixed and mobile installations.

Case Studies and Use Cases in South Africa

1. Underground Gold Mines in Gauteng

Mines in Gauteng adopted NSHXAFOE halogen-free cables after fire incidents highlighted the dangers of smoke inhalation.

Result: Reduced risk of toxic smoke in evacuation scenarios, improved compliance with Mine Health and Safety Act.

2. Coal Mining in Mpumalanga

NSGAFOEU oil-resistant cables used for powering mobile machinery where hydraulic oils and lubricants are pervasive.

Result: Extended cable lifespan compared to conventional PVC-jacketed cables, reducing downtime.

3. Renewable Energy Parks in Northern Cape

Large-scale solar farms integrated NSHXAFOE cables for medium voltage connections.

Result: Halogen-free properties aligned with environmental sustainability goals.

Frequently Asked Questions (FAQ)

1. What is the voltage rating of NSGAFOEU/NSHXAFOE cables?

They are designed for medium voltage applications, typically 1.8/3kV and 3.6/6kV.

2. Are these cables suitable for underground mining in South Africa?

Yes. Their oil resistance, flame retardance, and halogen-free variants make them ideal for underground conditions.

3. What is the main difference between NSGAFOEU and NSHXAFOE?

NSGAFOEU uses a chlorinated rubber sheath, while NSHXAFOE uses a halogen-free compound for improved fire safety.

4. Do these cables meet South African SANS standards?

They are certified under DIN VDE 0250 standards. While not identical to SANS 1520-1, they are accepted in specialized industrial projects.

5. Can they be used in renewable energy installations?

Yes, particularly in wind and solar farms, where medium voltage distribution is necessary.

6. How long is the service life of these cables?

With proper installation and maintenance, service life can exceed 15–20 years, depending on environmental conditions.

NSGAFOEU and NSHXAFOE medium voltage single core cables represent a robust, reliable, and safe solution for power distribution in demanding industrial environments. Their oil resistance, flame retardance, and halogen-free properties make them indispensable in South African mining, heavy industry, transport, and renewable energy sectors.

As South Africa faces increasing demands for safe, efficient, and sustainable power infrastructure, these cables offer an effective answer to the challenges of harsh operating conditions, safety regulations, and environmental considerations. By combining technical excellence with practical application benefits, NSGAFOEU and NSHXAFOE cables stand as a benchmark for modern medium voltage power distribution.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430