Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)SHOEU 0.6/1kV Flexible Cable VDE 0250 Part 812

(N)SHOEU 0.6/1kV Flexible Cable: Essential Technology for South Africa’s Mining and Heavy Industry

(N)SHOEU 0.6/1kV Flexible cable VDE 0250 Part 812

Applications | These cables are designed for use in open cast miningfactories for laying of excavators and conveyor beltswith permanent movements between parts of thee quipment.These cables are used where the ascending pipe servesas earth conductor, for instance for submersible pumps. |

Standards | VDE 0250 Part 812 |

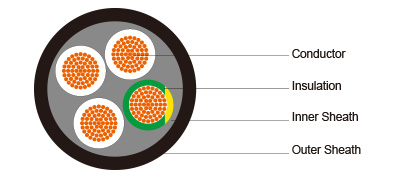

Construction | |

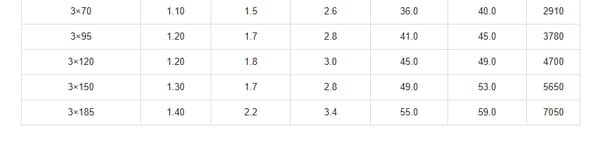

Conductors | Flexible stranded copper conductor, class 5 according to DIN VDE 0295/IEC 60228. |

Insulation | EPR. |

Earth Conductor (for –J type) | Incorporatedas a fourth core or split into three in theouter interstices. |

InnerSheath | EPR. |

Outer Sheath | CM type 5GM5. |

What Are (N)SHOEU Flexible Cables?

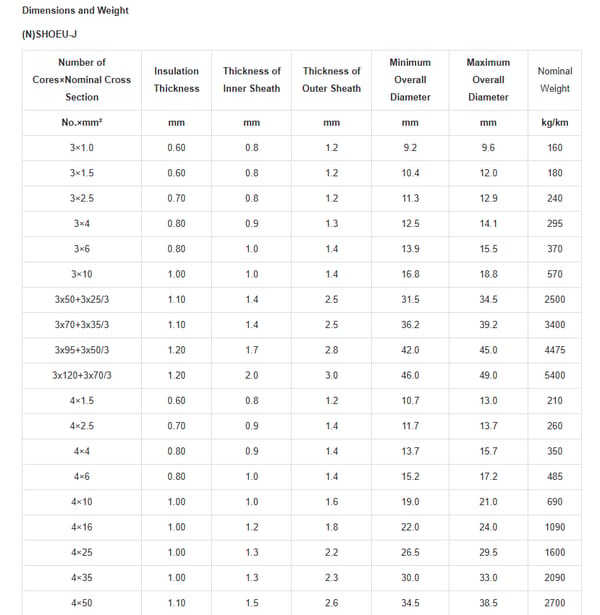

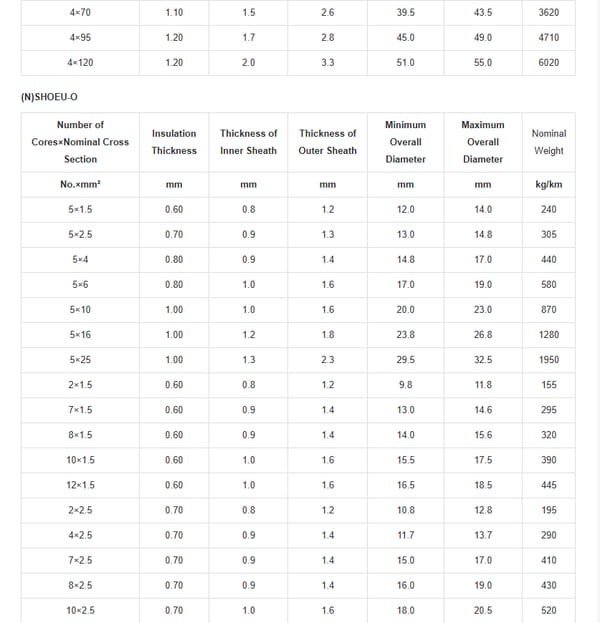

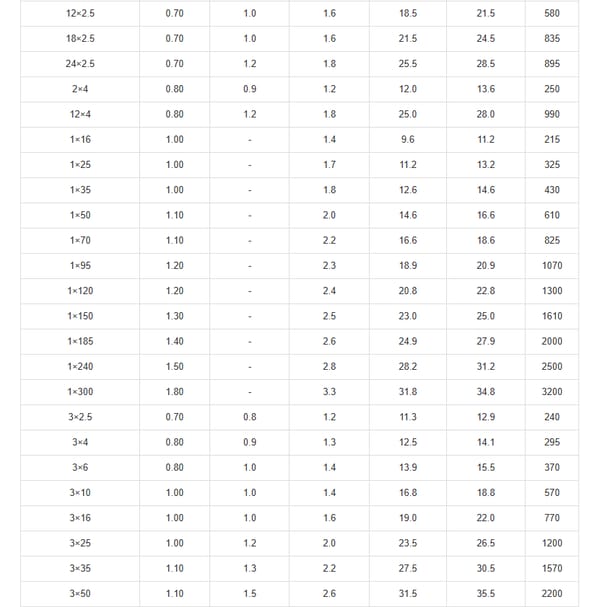

(N)SHOEU cables are heavy-duty, flexible power cables designed for applications requiring constant movement and high mechanical stress. Their construction ensures they can withstand harsh conditions, including extreme temperatures, abrasion, and chemical exposure, which are common in mining and industrial environments. Available in two variants—(N)SHOEU-J (with an earth conductor) and (N)SHOEU-O (without an earth conductor)—these cables are tailored to specific operational needs.

Benefits of (N)SHOEU Flexible Cables

Flexibility: The Class 5 copper conductors and EPR insulation allow the cables to bend and flex without damage, ideal for dynamic applications like conveyor belts and excavators.

Durability: The CM 5GM5 outer sheath resists abrasion, oils, and chemicals, ensuring longevity in harsh mining environments.

Safety: The (N)SHOEU-J variant includes an earth conductor, reducing the risk of electrical faults in high-risk settings.

Versatility: With a wide range of core counts and cross-sections, these cables support diverse applications, from small pumps to large industrial machinery.

Compliance: Adherence to VDE 0250 Part 812 ensures reliability and safety, meeting international standards.

Applications in South Africa’s Mining and Heavy Industry

South Africa’s mining sector, a cornerstone of the economy, relies heavily on robust infrastructure to maintain productivity. (N)SHOEU cables are widely used in open-cast mining operations, such as those in the Mpumalanga coal fields and the Northern Cape’s iron ore mines. Their flexibility and durability make them ideal for:

Excavators and Draglines: These cables power and control heavy machinery that operates continuously, enduring constant movement and mechanical stress.

Conveyor Belts: In coal and diamond mines, (N)SHOEU cables connect moving parts of conveyor systems, ensuring reliable power delivery.

Submersible Pumps: The cables’ resistance to water and chemicals makes them suitable for dewatering operations in deep mines.

Case Study: Enhancing Safety in a Mpumalanga Coal Mine

In 2024, a major coal mine in Mpumalanga faced challenges with frequent cable failures in its conveyor belt system, leading to costly downtime. By upgrading to (N)SHOEU-J 3×50+3×25/3 cables, the mine improved safety and reliability. The earth conductor reduced the risk of electrical faults, while the cable’s flexibility accommodated the conveyor’s constant motion. Post-installation, downtime decreased by 30%, and maintenance costs dropped significantly, demonstrating the cables’ value in high-stakes environments.

Installation Recommendations

Proper installation is crucial to maximizing the performance and lifespan of (N)SHOEU cables. Follow these guidelines:

Site Assessment: Evaluate the environment for factors like temperature, chemical exposure, and mechanical stress. Ensure the cable’s specifications match the application’s demands.

Cable Handling: Avoid sharp bends or twisting during installation to prevent damage to the conductors or insulation.

Securing Cables: Use appropriate cable trays or clamps to secure cables, especially in dynamic applications like excavators, to minimize wear.

Connection Integrity: Ensure connections are tight and use compatible connectors to prevent electrical faults.

Environmental Protection: In wet or corrosive environments, use additional protective conduits to shield the cables.

Maintenance Recommendations

Regular maintenance ensures (N)SHOEU cables perform reliably over their lifespan:

Visual Inspections: Check for signs of abrasion, cuts, or chemical degradation on the outer sheath. Schedule inspections monthly in high-stress environments.

Electrical Testing: Periodically test insulation resistance and continuity to detect potential faults early.

Cleaning: Remove dirt, oil, or chemicals from the cable surface to prevent degradation of the outer sheath.

Replacement Schedule: Replace cables showing significant wear or damage, particularly in critical applications like submersible pumps.

Usage Scenarios

(N)SHOEU cables are versatile and can be deployed in various scenarios:

Open-Cast Mining: Powering heavy machinery in gold, platinum, and coal mines.

Heavy Industry: Supporting factories with dynamic equipment, such as steel mills or cement plants.

Temporary Installations: Providing power for temporary setups, like mobile crushers at remote mining sites.

Submersible Applications: Used in dewatering systems where cables are exposed to water and chemicals.

Case Study: Temporary Power for a Northern Cape Iron Ore Project

In 2025, a new iron ore mine in the Northern Cape required a temporary power solution for its mobile crushing units during the exploration phase. (N)SHOEU-O 5×25 cables were chosen for their flexibility and ease of installation. The cables powered the crushers efficiently, and their robust construction withstood the dusty, abrasive environment. This solution allowed the project to proceed without delays, highlighting the cables’ adaptability for temporary setups.

Frequently Asked Questions (FAQs)

Q: What is the difference between (N)SHOEU-J and (N)SHOEU-O cables?

A: (N)SHOEU-J cables include an earth conductor for added safety, making them suitable for applications requiring grounding, like submersible pumps. (N)SHOEU-O cables lack an earth conductor and are used in simpler setups.

Q: Can (N)SHOEU cables be used in extreme temperatures?

A: Yes, the EPR insulation and CM 5GM5 outer sheath allow these cables to operate in temperatures ranging from -40°C to +80°C.

Q: How often should (N)SHOEU cables be replaced?

A: Replacement depends on usage and environmental conditions. Regular inspections can extend their lifespan, but heavily stressed cables may need replacement every 5–10 years.

Q: Are (N)SHOEU cables suitable for underground mining?

A: While primarily designed for open-cast mining, they can be used underground if protected from excessive moisture and mechanical damage.

Q: How do I choose the right (N)SHOEU cable for my application?

A: Consider the power requirements, core count, cross-section, and environmental conditions. Consult the technical specifications and a cable specialist for guidance.

(N)SHOEU flexible cables are a cornerstone of South Africa’s mining and heavy industry, offering unmatched flexibility, durability, and safety. Their ability to withstand the rigors of open-cast mining, heavy machinery, and submersible applications makes them a preferred choice for operators seeking reliable power solutions. By following proper installation and maintenance practices, businesses can maximize the benefits of these cables, reducing downtime and enhancing safety. As South Africa’s mining sector continues to evolve, (N)SHOEU cables will remain a vital technology, supporting the industry’s growth and sustainability goals.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430