Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NSHTOEU 0.6/1kV LHD Cables VDE 0250 Part 814

NSHTOEU 0.6/1kV LHD Cables: Used for frequently changing dynamic loads, such as reeling cables for scoops (LHDs) in underground mines, suitable for mono-spiral reels and cylindrical reels.

NSHTOEU 0.6/1kV LHD Cables VDE 0250 Part 814

Applications | These cables are used for frequently changing dynamic loads, such as reeling cables for scoops (LHDs) in underground mines, suitable for mono-spiral reels and cylindrical reels. |

Standards | VDE 0250 Part 814 |

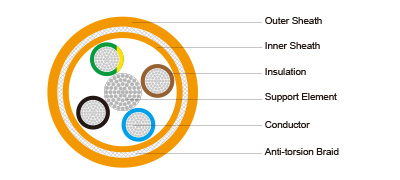

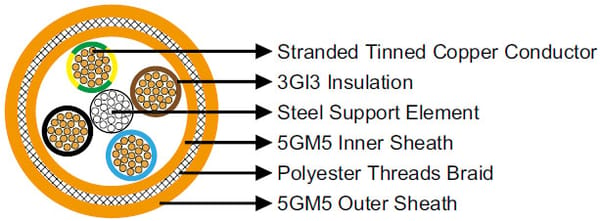

Construction  | |

Conductors | Flexible stranded tinned copper conductor. |

Insulation | EPR type 3GI3. |

Support Element | Central steel support element. |

Inner Sheath | PCP type 5GM5. |

Anti-torsion Braid | Reinforced braid of polyester threads in a vulcanized bond between inner and outer sheath. |

Outer Sheath | PCP type 5GM5. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

4x16(6 kN) | 27.5 | 31.5 | 1500 |

4x35(12 kN) | 37.5 | 42.0 | 2920 |

4x50(12 kN) | 43.0 | 48.0 | 3970 |

4x50(30 kN) | 42.0 | 44.0 | 3660 |

4x70 (20kN) | 47.0 | 52.0 | 5530 |

4x95 (50kN) | 53.0 | 58.0 | 6500 |

NSHTOEU 0.6/1kV cables are engineered for the demanding conditions of underground mining, particularly for Load Haul Dump (LHD) operations in SCOOP applications. These cables prioritize safety, reliability, and performance in extreme environments.

Key Features

Durability: Built to withstand the harsh conditions of underground mining, ensuring long-term performance.

Flexibility: Designed for dynamic, high-mobility applications, including reeling systems.

Safety and Compliance: Meets stringent international standards, including DIN VDE 0250-814 and MSHA certifications, ensuring global safety and performance benchmarks.

Dynamic Load Management: Handles frequently changing loads without compromising efficiency or reliability.

Applications

Mining SCOOPS (LHD Machines): Supports material transportation in extreme underground environments, ensuring seamless operation.

Mono-Spiral and Cylindrical Reels: Ideal for reeling applications requiring flexibility and durability.

High-Mobility Operations: Suited for dynamic tasks in underground mining where equipment is pushed to its limits.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430