Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NSSHCGEOEU 0.6/1kV Coal Cutter Cable (Low Tensile Stress) VDE 0250 Part 812

Revolutionizing Heavy Industry: Exploring NSSHCGEOEU 0.6/1kV Coal Cutter Cable for South African Mining Excellence

Applications | These cables are used for the connection of mobile machines under extremelyhigh mechanical loads, predominantly in miningsituations,e.g. for coal-cutting machines, suitable for extreme bending loads under low tensile stress. |

Standards | DIN VDE 0250 Part 812 |

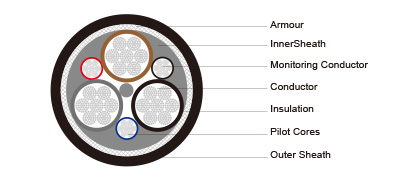

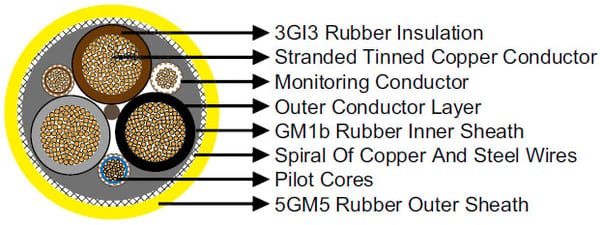

Construction  | |

Conductors | Flexible stranded tinned copper conductor. |

Insulation | Heatresistant3GI3 rubber based on EPR. |

Outer Conductor Layer | Easy strippable outer conductive layer. |

Pilot Cores | Copper strand and steelbraid conductor capable ofexpansion and compression with EPRrubber insulation. |

Monitoring Conductor | Spiral of tinned copper wires above the pilot cores, covered with a semi-conductive tape. |

InnerSheath | Rubber type GM1b. |

Armour/Earth Conductor | Concentric earth conductor as spiral of copper and steel wires,fibreglas tape, embedded in the outer sheath whichprevents sheath exchanging. |

Outer Sheath | Rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×16/16KON+2ST+UEL | 35.0 | 38.0 | 2130 |

3×25/16KON+2ST+UEL | 38.0 | 41.0 | 2790 |

3×35/16KON+2ST+UEL | 41.0 | 45.0 | 3390 |

3×50/25KON+2ST+UEL | 47.0 | 51.0 | 4340 |

3×70/35KON+2ST+UEL | 52.0 | 56.0 | 5680 |

3×95/50KON+2ST+UEL | 58.0 | 62.0 | 7180 |

3×25/16KON+3×(1.5ST+UEL) | 38.0 | 41.0 | 2920 |

3×35/16KON+3×(1.5ST+UEL) | 41.0 | 45.0 | 3630 |

3×50/25KON+3×(1.5ST+UEL) | 45.0 | 48.0 | 4500 |

3×70/35KON+3×(1.5ST+UEL) | 48.0 | 53.0 | 5850 |

3×95/50KON+3×(1.5ST+UEL) | 52.0 | 56.0 | 7400 |

3×120/70KON+3×(1.5ST+UEL) | 58.0 | 63.0 | 8300 |

3×150/70KON+3×(1.5ST+UEL) | 62.0 | 68.0 | 9300 |

Benefits of NSSHCGEOEU Coal Cutter Cable

The NSSHCGEOEU cable offers several advantages that make it a preferred choice in South Africa’s mining industry:

Durability Under Extreme Conditions: The abrasion-resistant and tear-resistant 5GM5 outer sheath ensures longevity in harsh mining environments.

Flexibility for Mobile Applications: The cable’s design accommodates extreme bending stresses, making it ideal for mobile machinery like coal cutters.

Oil and Flame Resistance: The outer sheath’s oil and flame-retardant properties enhance safety in volatile mining settings.

Reliable Monitoring: The monitoring conductor allows continuous checks on cable integrity, reducing downtime due to faults.

Corrosion Resistance: Tinned copper conductors and steel braid components resist corrosion, extending the cable’s lifespan.

Compliance with Standards: Adherence to DIN VDE 0250 Part 812 ensures reliability and safety in high-stakes applications.

Installation Recommendations

Proper installation of the NSSHCGEOEU cable is critical to maximizing its performance and lifespan. Here are key guidelines:

Site Assessment: Evaluate the mining environment for factors like temperature, moisture, and mechanical stress. Ensure the cable’s specifications match the operational requirements.

Cable Handling: Avoid excessive bending or twisting during installation to prevent damage to the flexible conductors and insulation.

Securing the Cable: Use appropriate cable management systems, such as trays or clamps, to minimize movement and abrasion during operation.

Grounding: Ensure the concentric earth conductor is properly connected to the grounding system to prevent electrical hazards.

Avoid Overloading: Select a cable configuration (e.g., 3×50/25KON+2ST+UEL) that matches the power demands of the connected machinery to prevent overheating.

Environmental Protection: In areas with high oil exposure or chemical presence, ensure the cable’s outer sheath is intact and free from cuts or abrasions.

Maintenance Recommendations

Regular maintenance ensures the NSSHCGEOEU cable remains operational in demanding mining environments:

Visual Inspections: Check for signs of wear, such as abrasions, cuts, or exposed conductors, especially in high-movement areas.

Monitoring Conductor Checks: Use the monitoring conductor to detect faults or insulation breakdowns early, reducing the risk of unexpected failures.

Cleaning: Remove dust, coal particles, or oil residues from the outer sheath to maintain its protective properties.

Testing: Periodically test the cable’s electrical performance, including insulation resistance and continuity, to ensure compliance with safety standards.

Replacement: Replace cables showing significant wear or damage, particularly in high-stress mining applications, to prevent downtime or safety risks.

Usage Scenarios in South Africa’s Mining Industry

South Africa’s mining sector, a cornerstone of the economy, relies heavily on robust infrastructure to maintain productivity. The NSSHCGEOEU cable is particularly suited for the following scenarios:

Underground Coal Mining

In South Africa’s coal-rich regions, such as Mpumalanga, coal-cutting machines operate in confined, dusty, and high-stress environments. The NSSHCGEOEU cable’s flexibility and durability ensure reliable power delivery to these machines, reducing downtime and maintenance costs.

Heavy Industry Applications

Beyond mining, the cable is used in heavy industries like steel production and mineral processing, where mobile equipment faces similar mechanical challenges. Its oil-resistant and flame-retardant properties make it suitable for environments with high fire risks.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430