Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)SSHOEU 0.6/1kV Heavy Duty Flexible Cable VDE 0250 Part 812

How (N)SSHOEU heavy duty flexible cables enhance South Africa’s mining and heavy industry with durability, safety, and efficiency

Applications | These cables are used for connection of mobileequipment and machines under very high mechanicalloads in dry and damp areas, outdoors and in explosionhazard areas, particularly in mining and at quarries andbuilding sites. |

Standards | Based on VDE 0250 Part 812 |

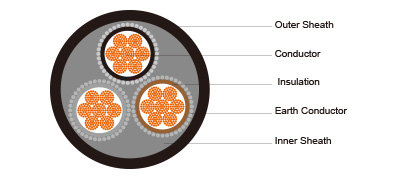

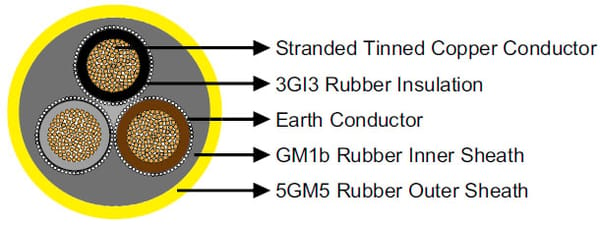

Construction  | |

Conductors | Flexible stranded copper conductor, class 5 according to DIN VDE 0295. |

Insulation | Rubber type 3GI3. |

Pilot Cores (optional) | Tinned copper conductor with EPR insulation. |

Earth Conductor | Spiral of tinnedcopper wires. |

InnerSheath | Rubber type GM1b. |

Outer Sheath | Rubber type 5GM5. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

3x2.5+3x2.5/3E | 14.0 | 17.0 | 300 |

3x6+3x6/3E | 18.0 | 21.0 | 580 |

3x10+3x10/3E | 21.0 | 25.0 | 860 |

3x2.5+3x2.5/3E+3x1.5 | 17.0 | 20.0 | 450 |

3x6+3x6/3E+3x1.5 | 18.0 | 22.0 | 660 |

3x10+3x10/3E+3x2.5 | 21.0 | 26.0 | 950 |

3x25+3x16/3E+3x2.5 | 28.0 | 33.0 | 1660 |

3x35+3x16/3E+3x2.5 | 30.0 | 35.0 | 1970 |

3x50+3x25/3E+3x2.5 | 36.0 | 41.0 | 2840 |

3x70+3x35/3E+3x2.5 | 41.0 | 46.0 | 3700 |

3x95+3x50/3E+3x2.5 | 47.0 | 52.0 | 4950 |

3x120+3x70/3E+3x2.5 | 52.0 | 57.0 | 5650 |

3x150+3x70/3E+3x2.5 | 58.0 | 63.0 | 6520 |

What Are (N)SSHOEU Cables?

The (N)SSHOEU cable is a robust, flexible power cable engineered for high mechanical loads in challenging environments. Compliant with VDE 0250 Part 812, it is specifically designed for mobile equipment in mining, quarries, and construction sites, including explosion-hazard areas. Its flexibility, durability, and resistance to environmental stressors make it ideal for applications where standard cables would fail.

Benefits of (N)SSHOEU Cables

Durability and Flexibility

The rubber-based insulation and sheathing make (N)SSHOEU cables exceptionally durable, capable of withstanding mechanical stress, bending, and twisting without compromising performance. This is critical in mining, where cables are dragged across rough terrain or coiled around mobile equipment.

Safety in Hazardous Environments

The inclusion of earth conductors and optional pilot cores enhances safety by preventing electrical faults and enabling real-time monitoring. Their suitability for explosion-hazard areas, common in South African mines, ensures compliance with stringent safety regulations.

Environmental Resistance

The 5GM5 outer sheath resists oils, chemicals, UV radiation, and extreme temperatures, making these cables ideal for South Africa’s diverse climates, from the scorching Northern Cape to the humid KwaZulu-Natal coast.

Versatility

With configurations ranging from 3x2.5 mm² to 3x150 mm², (N)SSHOEU cables support a wide array of applications, from powering small tools to massive mining drills.

Usage Scenarios in South Africa

Mining Sector

South Africa’s mining industry, a cornerstone of the economy, relies heavily on robust power solutions. (N)SSHOEU cables are widely used in:

Underground Mining: In gold and platinum mines, such as those in the Witwatersrand Basin, these cables power drilling rigs, ventilation systems, and conveyor belts. Their flexibility allows them to navigate tight, winding tunnels, while their explosion-proof design ensures safety in methane-rich environments.

Open-Pit Mining: In diamond mines like those in Kimberley, (N)SSHOEU cables connect mobile crushers and excavators, enduring dust, vibration, and extreme temperatures.

Heavy Industry

Beyond mining, these cables support South Africa’s heavy industries:

Construction Sites: In infrastructure projects, such as the expansion of Gauteng’s road networks, (N)SSHOEU cables power cranes and concrete mixers, offering flexibility for temporary setups.

Quarries: In limestone quarries supplying cement production, these cables withstand abrasive dust and heavy machinery vibrations.

Case Studies in South Africa

Case Study 1: Enhancing Safety in a Platinum Mine

In 2024, a major platinum mine in Rustenburg faced frequent cable failures due to the abrasive underground environment. By switching to (N)SSHOEU 3x50+3x25/3E+3x2.5 cables, the mine reduced downtime by 30%. The cables’ robust 5GM5 sheath resisted abrasion, while the earth conductor ensured compliance with South Africa’s Mine Health and Safety Act. The pilot cores enabled real-time monitoring, allowing operators to detect faults before they caused outages.

Case Study 2: Powering a Quarry Expansion

A limestone quarry in the Eastern Cape, supporting South Africa’s booming cement industry, upgraded its mobile crushers in 2025. The quarry adopted (N)SSHOEU 3x95+3x50/3E+3x2.5 cables to handle the increased power demands. The cables’ UV resistance and flexibility allowed reliable operation across the quarry’s dusty, sun-exposed terrain, reducing maintenance costs by 15% compared to previous solutions.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430