Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NSSHOEU .../3E + ST 0.6/1kV Heavy Duty Flexible Cable VDE 0250 Part 812

Heavy Duty Flexible NSSHOEU .../3E + ST 0.6/1kV Cables for Mining and Industry

NSSHOEU .../3E + ST 0.6/1kV Heavy Duty Flexible Cable VDE 0250 Part 812

Applications | These cables are designed for the connection of mobile equipment and machines under very high mechanical loads in dry and damp areas, outdoors and in explosion hazard areas, particularly in mining and industry, quarries and building sites. |

Standards | VDE 0250 Part 812 |

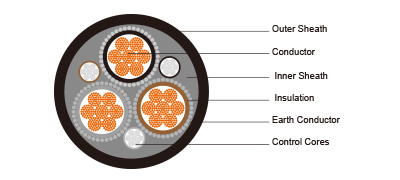

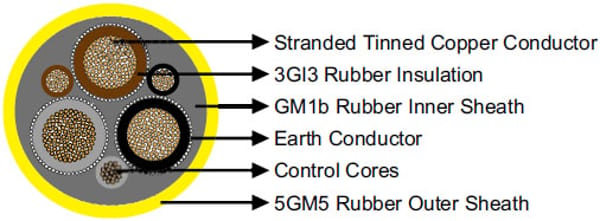

Construction  | |

Conductors | Flexible stranded tinned copper conductor, class 5 according to DIN VDE 0295. |

Insulation | Heat resistant EPR type 3GI3. |

Earth Conductor | Distributed as spiral of tinned copper wires over core insulating coverings (coding .../3E) or located concentrically between the inner and outer sheaths (coding ...kon). |

Control Cores | Laid in the interstices, film wrap. |

InnerSheath | Rubber type GM1b. |

Outer Sheath | Chlorinated rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

3×2.5+3×2.5/3E | 15.0 | 18.0 | 410 |

3×4+3×4/3E | 19.0 | 22.0 | 500 |

3×6+3×6/3E | 18.0 | 21.0 | 660 |

3×10+3×10/3E | 22.0 | 26.0 | 950 |

3×16+3×16/3E | 28.0 | 32.0 | 1350 |

3×25+3×16/3E | 29.0 | 33.0 | 1800 |

3×50+3×25/3E | 40.0 | 44.0 | 3300 |

3×70+3×35/3E | 44.0 | 49.0 | 4360 |

3×95+3×50/3E | 52.0 | 57.0 | 5740 |

3×120+3×70/3E | 56.0 | 61.0 | 6870 |

3×150+3×70/3E | 62.0 | 68.0 | 8140 |

3×2.5+3×2.5/3E+3×1.5ST | 18.0 | 20.0 | 500 |

3×4+3×4/3E+3×1.5ST | 19.0 | 22.0 | 550 |

3×6+3×6/3E+3×1.5ST | 20.0 | 24.0 | 810 |

3×10+3×10/3E+3×2.5ST | 24.0 | 28.0 | 1150 |

3×16+3×16/3E+3×2.5ST | 28.0 | 32.0 | 1470 |

3×25+3×16/3E+3×2.5ST | 30.0 | 34.0 | 1960 |

3×35+3×16/3E+3×2.5ST | 34.0 | 38.0 | 2590 |

3×50+3×25/3E+3×2.5ST | 41.0 | 46.0 | 3560 |

3×70+3×35/3E+3×2.5ST | 44.0 | 49.0 | 4470 |

3×95+3×50/3E+3×2.5ST | 52.0 | 57.0 | 5850 |

3×120+3×70/3E+3×2.5ST | 51.0 | 56.0 | 6800 |

3×150+3×70/3E+3×2.5ST | 59.0 | 64.0 | 8100 |

3×2.5/2.5KON | 14.0 | 17.0 | 380 |

5×2.5/2.5KON | 18.0 | 21.0 | 560 |

5×4/4KON | 20.0 | 24.0 | 710 |

5×6/6KON | 20.0 | 24.0 | 910 |

10×1.5/1.5KON | 20.0 | 24.0 | 800 |

10×2.5/2.5KON | 26.0 | 29.0 | 1100 |

Applications

NSSHOEU cables are versatile and widely used in:

Mining operations: powering drilling rigs, conveyors, pumps, and mobile machinery exposed to constant vibration, bending, and abrasion.

Quarries and construction sites: supplying crushers, mixers, and heavy lifting equipment.

Industrial facilities: powering machines in steel plants, cement factories, and chemical industries.

Hazardous areas: compliant with safety standards for environments with flammable gas or dust, critical in South African coal mines.

Outdoor applications: resistant to UV and weathering, making them suitable for exposed installations.

Benefits

1. High Mechanical Strength

Designed to withstand crushing forces, sharp bends, and repetitive movement without compromising insulation or conductor integrity.

2. Environmental Resistance

The outer sheath resists oil, flames, UV radiation, and chemicals, extending cable lifespan in mining and heavy industry.

3. Safety in Hazardous Areas

The flame-retardant sheath minimizes fire risks, while the earth conductor system ensures reliable fault current protection.

4. Long Service Life

By reducing wear and tear, these cables lower replacement frequency, saving costs for mining companies in South Africa.

5. Compliance with International Standards

Built according to VDE 0250 Part 812, ensuring compatibility with global and local safety frameworks.

Case Study: South Africa’s Platinum Mining Sector

Platinum mining in Rustenburg and the Bushveld Complex is one of the toughest environments for electrical infrastructure. Machinery operates deep underground, where cables face extreme bending cycles, abrasive rock, and exposure to oil and water.

A leading South African platinum producer adopted NSSHOEU 3×95+3×50/3E cables to power underground conveyor systems. Compared to standard flexible cables, NSSHOEU variants lasted 40% longer before needing replacement. This reduced downtime and maintenance costs significantly, while also improving safety by lowering the risk of insulation failure.

Installation Recommendations

To maximize the service life of NSSHOEU cables, proper installation practices are critical:

Avoid sharp bends: adhere to minimum bending radius requirements (typically 6–8 × cable diameter).

Support moving cables: use cable trays, rollers, or festoon systems for mobile equipment.

Correct termination: ensure high-quality cable glands and connectors to prevent ingress of dust or water.

Proper grounding: connect earth conductors securely to ensure safe fault current return.

Maintenance Best Practices

Regular inspections: check for cuts, abrasions, or sheath wear, especially in moving sections.

Thermal monitoring: overheating may indicate overloading or poor ventilation.

Cleaning: remove accumulated dust, oil, and chemicals that can degrade the sheath.

Scheduled replacement: even with durability, cables should be replaced proactively before catastrophic failure.

Frequently Asked Questions (FAQ)

1. Are NSSHOEU cables suitable for underground coal mines in South Africa?

Yes. Their flame-retardant sheath and mechanical robustness make them ideal for coal mining environments where explosion hazards exist.

2. Can NSSHOEU cables be used for outdoor cranes and lifting equipment?

Yes. They are UV-resistant and can withstand outdoor exposure, making them suitable for cranes, hoists, and port equipment.

3. How long do these cables typically last in mining environments?

Service life depends on stress levels, but with proper installation and maintenance, they can last 3–5 years, longer than many alternatives.

4. Do they comply with South African standards?

Yes. While based on VDE 0250 Part 812, NSSHOEU cables also meet NRCS safety requirements for use in South Africa.

5. What sizes are most commonly used in mining?

Large cross-sections like 3×95+3×50/3E and 3×120+3×70/3E are widely used for high-power equipment underground.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430