Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NSSHOEU-O/J 0.6/1kV Heavy Duty Flexible Cable VDE 0250 Part 812

NSSHOEU-O/J Heavy-Duty Flexible Cables: Powering South Africa’s Mining and Industrial Sectors with Unmatched Durability

NSSHOEU-O/J 0.6/1kV Heavy Duty Flexible Cable VDE 0250 Part 812

Applications | These cables are designed for the connection of mobile equipment and machines under very high mechanical loads in dry and damp areas, outdoors and in explosion hazard areas, particularly in mining and industry, quarries and building sites. |

Standards | VDE 0250 Part 812 |

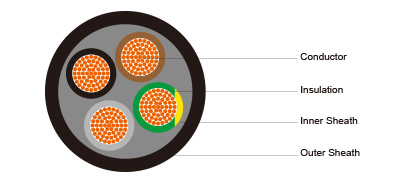

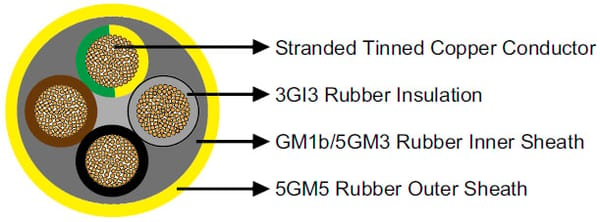

Construction  | |

Conductors | Flexible stranded tinned copper conductor, class 5 according to DIN VDE 0295. |

Insulation | Heat resistant EPR type 3GI3. |

InnerSheath () | SR/SBR/PCP/CRtype GM1b/5GM3. |

Outer Sheath | Chlorinated rubber PCP/CR type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

NSSHOEU-O

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

1×16 | 11.0 | 13.0.5.0 | 260 |

1×25 | 13.0 | 16.0 | 390 |

1×35 | 14.0 | 17.0 | 500 |

1×50 | 16.0 | 19.0 | 680 |

1×70 | 18.0 | 21.0 | 900 |

1×95 | 20.0 | 24.0 | 1150 |

1×120 | 23.0 | 27.0 | 1440 |

1×150 | 24.0 | 28.0 | 1750 |

1×185 | 28.0 | 31.0 | 2300 |

1×240 | 32.0 | 36.0 | 3000 |

2×1.5 | 11.0 | 14.0 | 210 |

3×2.5 | 13.0 | 16.0 | 300 |

NSSHOEU-J

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No. ×mm² | mm | mm | kg/km |

3×1.5 | 12.0 | 15.0 | 240 |

3×70/35 | 46.0 | 51.0 | 4450 |

3×95/50 | 54.0 | 59.0 | 5870 |

3×120/70 | 59.0 | 64.0 | 7340 |

4×1.5 | 13.0 | 16.0 | 280 |

4×2.5 | 15.0 | 18.0 | 400 |

4×4 | 17.0 | 20.0 | 510 |

4×6 | 18.0 | 21.0 | 630 |

4×10 | 22.0 | 26.0 | 950 |

4×16 | 28.0 | 32.0 | 1430 |

4×25 | 33.0 | 37.0 | 2100 |

4×35 | 36.0 | 40.0 | 2650 |

4×50 | 42.0 | 47.0 | 3660 |

5×1.5 | 13.0 | 16.0 | 320 |

5×2.5 | 16.0 | 19.0 | 470 |

5×4 | 18.0 | 21.0 | 600 |

5×6 | 20.0 | 24.0 | 780 |

5×10 | 24.0 | 28.0 | 1130 |

5×16 | 29.0 | 34.0 | 1720 |

5×25 | 35.0 | 39.0 | 2470 |

6×2.5 | 13.0 | 16.0 | 300 |

7×1.5 | 16.0 | 19.0 | 470 |

7×2.5 | 18.0 | 21.0 | 600 |

10×1.5 | 19.0 | 22.0 | 570 |

10×2.5 | 21.0 | 25.0 | 790 |

12×2.5 | 22.0 | 26.0 | 860 |

18×2.5 | 28.0 | 32.0 | 1240 |

The NSSHOEU-O/J cables are engineered for durability and performance, making them ideal for mobile machinery in extreme conditions. Below is a breakdown of their key features and corresponding benefits:

Feature | Benefit |

|---|---|

Exceptional Flexibility | Withstands continuous reeling, bending, and twisting without damage. |

Abrasion Resistance | Resists wear from rough surfaces and reeling equipment, extending cable life. |

Chemical Resistance | Protects against oils, fuels, and solvents common in industrial settings. |

High Tensile Strength | Ensures durability under mechanical stress and tension in reeling systems. |

Low Bending Radius | Enables compact installations in tight spaces with frequent movement. |

Temperature Resilience | Operates reliably from -40°C to +90°C, ideal for South Africa’s climate. |

Enhanced Electrical Conductivity | Delivers consistent power for high-demand equipment. |

Flame Retardancy | Enhances safety by reducing fire risks in hazardous environments. |

Long Service Life | Reduces replacement frequency, lowering maintenance costs. |

These features make NSSHOEU-O/J cables a game-changer for industries requiring reliable power delivery under punishing conditions.

Applications in South Africa’s Industrial Landscape

The NSSHOEU-O/J cables are versatile, supporting a variety of applications in South Africa’s key industries:

Mining Operations

South Africa’s mining sector, a global leader in platinum and gold production, relies on equipment like drilling rigs, conveyor belts, and haul trucks. NSSHOEU-O/J cables power these machines in underground and surface mines, withstanding dust, moisture, and abrasive surfaces. Their flame-retardant properties are critical in environments with explosion risks, enhancing worker safety.Construction Sites

On construction sites across Gauteng and the Western Cape, tower cranes, excavators, and mobile generators benefit from the cables’ flexibility and abrasion resistance. These properties ensure reliable power delivery during frequent equipment movement over rough terrain.Port and Terminal Operations

South Africa’s ports, such as Durban and Cape Town, handle significant cargo volumes. NSSHOEU-O/J cables power cranes and automated systems, offering resistance to saltwater and oils, ensuring uninterrupted operations during peak shipping periods.Heavy Industry

In steel plants and manufacturing facilities in Mpumalanga, these cables support high-power machinery, delivering consistent performance in dusty, high-temperature environments.

The NSSHOEU-O/J heavy-duty flexible cables are a cornerstone of reliable power delivery for South Africa’s mining, construction, and heavy industry sectors. Their exceptional durability, flexibility, and resistance to harsh conditions make them indispensable for mobile machinery operating in challenging environments. By reducing downtime, enhancing safety, and offering long-term cost savings, these cables address the unique needs of South Africa’s industrial landscape. As the country continues to innovate and prioritize sustainability, NSSHOEU-O/J cables are poised to play a pivotal role in powering its industrial future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430