Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTMCWOEU Flexible Medium-Voltage Single Core Cable VDE 0250 Part 813

NTMCWOEU Flexible Medium-Voltage Single Core Cable: Engineered for High-performance Connections in Demanding Environments

NTMCWOEU Flexible Medium-Voltage Single Core Cable VDE 0250 Part 813

Applications | These cables are used for connection in switch-gear and for connection of mobile transformer substations to the overhead line. |

Standards | VDE 0250 Part 813 |

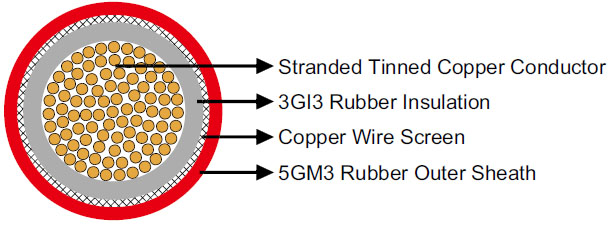

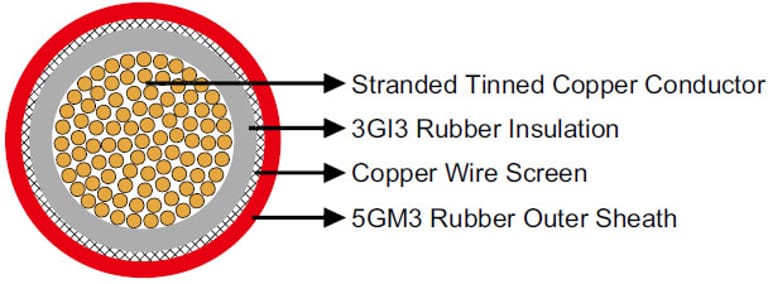

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Special conductive rubber. |

Insulation | EPR type 3GI3. |

Outer Conductor Layer | Special conductive rubber. |

Screen | Spiral of tinned copper wires. |

Outer Sheath | PCP type 5GM3. |

Dimensions and Weight

6/10kV

Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Outer Sheath | Nominal Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | mm | kg/km |

1×16/16 | 3.4 | 2.2 | 22.0 | 760 |

1×25/16 | 3.4 | 2.2 | 23.5 | 910 |

1×35/16 | 3.4 | 2.2 | 24.5 | 1040 |

1×50/16 | 3.4 | 2.2 | 27.0 | 1260 |

1×70/16 | 3.4 | 2.5 | 28.5 | 1530 |

1×95/16 | 3.4 | 2.5 | 30.5 | 1770 |

1×120/16 | 3.4 | 2.5 | 33.5 | 2180 |

1×150/25 | 3.4 | 3.0 | 35.0 | 2550 |

1×185/25 | 3.4 | 3.0 | 37.0 | 2900 |

1×240/25 | 3.4 | 3.5 | 41.0 | 3590 |

1×300/25 | 3.4 | 3.5 | 43.0 | 4280 |

1×400/35 | 3.4 | 4.0 | 46.0 | 5120 |

1×500/35 | 3.4 | 4.0 | 49.0 | 5950 |

1×630/35 | 3.4 | 4.0 | 53.5 | 7860 |

12/20kV

Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Outer Sheath | Nominal Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | mm | kg/km |

1×25/16 | 5.5 | 2.5 | 28.0 | 1180 |

1×35/16 | 5.5 | 2.5 | 29.5 | 1320 |

1×50/16 | 5.5 | 2.5 | 31.5 | 1560 |

1×70/16 | 5.5 | 3.0 | 34.0 | 1920 |

1×95/16 | 5.5 | 3.0 | 36.0 | 2190 |

1×120/16 | 5.5 | 3.0 | 38.0 | 2460 |

1×150/25 | 5.5 | 3.5 | 40.0 | 2990 |

1×185/25 | 5.5 | 3.5 | 42.0 | 3350 |

1×240/25 | 5.5 | 3.5 | 45.0 | 3990 |

1×300/25 | 5.5 | 3.5 | 48.0 | 4760 |

1×400/35 | 5.5 | 4.0 | 52.0 | 6100 |

1×500/35 | 5.5 | 4.0 | 56.0 | 7010 |

1×630/35 | 5.5 | 4.0 | 60.0 | 8180 |

14/25kV

Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Outer Sheath | Nominal Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | mm | kg/km |

1×25/16 | 6.8 | 3.0 | 30.5 | 1300 |

1×300/25 | 6.8 | 4.0 | 49.0 | 4900 |

18/30kV

Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Outer Sheath | Nominal Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | mm | kg/km |

1×50/16 | 8.0 | 3.0 | 35.0 | 1870 |

20/35 kV

Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Outer Sheath | Nominal Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | mm | kg/km |

1×95/16 | 9.5 | 3.5 | 44.0 | 2900 |

1×150/25 | 9.5 | 3.5 | 46.3 | 3600 |

1×240/25 | 9.5 | 4.0 | 51.7 | 5000 |

In South Africa, where mining and heavy industries drive a significant portion of the economy, reliable and robust electrical infrastructure is critical. One essential component ensuring efficient and safe power transmission in these sectors is the NTMCWOEU flexible medium-voltage single core cable. Designed according to the rigorous VDE 0250 Part 813 standard, these cables are engineered for high-performance connections in demanding environments such as underground mining operations, surface processing plants, and mobile transformer substations.

Understanding NTMCWOEU Flexible Medium-Voltage Single Core Cables

The NTMCWOEU cable is a flexible, medium-voltage, single core power cable designed to provide reliable electricity transmission under mechanically and electrically demanding conditions. It is commonly used for switch-gear connections and linking mobile transformer substations to overhead lines. The design incorporates multiple layers engineered to ensure electrical efficiency, flexibility, and mechanical durability.

Why Choose NTMCWOEU Cables

High Flexibility

The stranded copper conductor and conductive rubber layers allow for bending and twisting without compromising electrical performance, ideal for mobile or reconfigurable installations.Mechanical Strength

Robust outer sheathing ensures the cable resists abrasion, crushing, and impacts, which is critical in mining tunnels, loading areas, and heavy machinery zones.Electrical Reliability

The combination of EPR insulation and tinned copper screening ensures low electrical losses, high dielectric strength, and excellent fault containment.Chemical and Thermal Resistance

PCP and EPR materials provide protection against chemical spills, oils, and temperature fluctuations common in industrial environments.Compliance with International Standards

Designed according to VDE 0250 Part 813, NTMCWOEU cables meet stringent international requirements for safety, performance, and durability.

Usage Scenarios in South Africa

Mining Operations

South Africa is home to some of the world’s largest mining operations, including gold, platinum, and diamond mines. NTMCWOEU cables are particularly suited for:

Underground Tunnels: Flexible, abrasion-resistant cables are ideal for transporting power in confined and high-movement areas.

Mobile Transformer Substations: The cable’s mechanical flexibility allows easy connection to temporary or reconfigurable transformer units used in mining operations.

Processing Plants: Durable insulation and mechanical protection make these cables suitable for high-voltage power distribution in heavy processing environments.

Heavy Industries

Industries such as steel, cement, and chemical processing benefit from NTMCWOEU cables for:

Power Transmission: Medium-voltage distribution in high-load machinery areas.

Control Systems: Ensuring reliable connectivity between switchgear and industrial control panels.

Temporary Installations: Construction and refurbishment sites require flexible, high-performance cables for temporary power supply.

Frequently Asked Questions (FAQ)

Q1: Can NTMCWOEU cables be used outdoors in harsh weather conditions?

A: Yes, the PCP outer sheath and EPR insulation provide protection against UV, moisture, and chemical exposure, making them suitable for outdoor installation with appropriate support.

Q2: How often should NTMCWOEU cables be tested for electrical integrity?

A: Periodic testing every 6–12 months is recommended, depending on operational intensity and environmental conditions.

Q3: What is the minimum bending radius for these cables?

A: Typically 15–20 times the overall cable diameter, but always follow the manufacturer’s specifications to prevent insulation and conductor damage.

Q4: Are these cables compatible with South African mining regulations?

A: Yes, they meet international VDE standards and are suitable for South African mining operations, aligning with safety and operational compliance requirements.

Q5: Can these cables handle high short-circuit currents?

A: Yes, the combination of stranded copper conductors, conductive rubber layers, and tinned copper screening provides excellent short-circuit and fault current resistance.

The NTMCWOEU flexible medium-voltage single core cable is a technologically advanced solution for South Africa’s demanding mining and heavy industry sectors. Its combination of flexibility, mechanical durability, electrical reliability, and compliance with international standards makes it an ideal choice for power distribution in dynamic and challenging environments. From underground mining tunnels to high-load industrial machinery, NTMCWOEU cables provide reliable performance, reduced maintenance costs, and enhanced operational safety.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430