Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTMTWOEU 0.6/1kV Mine Hoist Cables VDE 0250 Part 813

Type NTMTWOEU Mine Hoist Rubber Cable 0.6/1kV

Applications | These cables are used as suspended cable for intrinsically safe control of user-operated mine hoists (lifts) with telephonic connection in underground mines. |

Standards | VDE 0250 Part 813 |

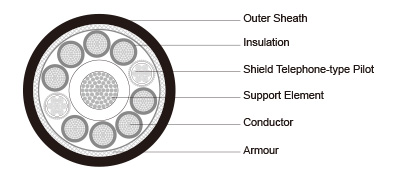

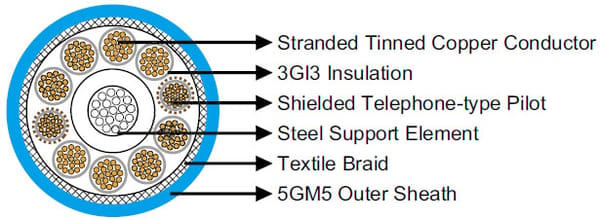

Construction  | |

Conductors | Flexible stranded tinned copper conductor, class 5 according to DIN VDE 0295. |

Insulation | EPR type 3GI3. |

Support Element | Central steel support element. |

Anti-torsion Braid | Textile braid. |

Outer Sheath | PCP rubber type 5GM5. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

8x2.5ST+2x1FM(C) | 21.7 | 23.7 | 800 |

8x2.5ST+10x (2x1FM)C | 34.0 | 37.5 | 1450 |

14x2.5ST+6x1FM(C) | 27.0 | 31.0 | 1200 |

18x2.5ST+6x1FM(C) | 38.0 | 42.0 | 1800 |

19x1.5(C)ST+6x (2x1FM)C | 35.1 | 38.1 | 2145 |

Applications

The Type NTMTWOEU 0.6/1kV Mine Hoist Cable is engineered for the demanding conditions of underground mining, offering robust construction and versatility for various applications:

Mine Hoisting Systems

Function: Provides reliable power and control transmission for hoisting systems.

Use Cases: Lifting ore, materials, or personnel in underground mining operations.

Benefits: Ensures smooth, efficient, and safe performance.

Material Handling Equipment

Function: Supports power and control needs for material handling equipment in mining environments.

Use Cases: Systems requiring frequent cable movement and flexibility.

Benefits: Withstands mechanical stress and frequent movement due to its durable and flexible design.

Harsh Environmental Conditions

Function: Operates reliably in challenging underground environments.

Use Cases: Exposure to oil, moisture, heat, and other environmental hazards.

Benefits: Rubber sheathing provides resistance to environmental stressors, ensuring consistent performance.

Benefits

The NTMTWOEU cable is a critical component for safe and efficient underground mining operations, offering the following advantages:

Enhanced Durability

Feature: Heavy-duty construction withstands harsh conditions, frequent bending, and high mechanical stress.

Advantage: Reduces the need for frequent replacements, extending cable lifespan.

Improved Safety

Feature: Oil-resistant and flame-retardant rubber sheath.

Advantage: Minimizes fire hazards and protects against damage, enhancing safety in underground environments.

Increased Flexibility

Feature: Multi-conductor design accommodates frequent bending and twisting.

Advantage: Ideal for dynamic applications like mine hoists, maintaining integrity under constant movement.

Reliable Performance

Feature: Multi-core design ensures robust power and control signal transmission.

Advantage: Minimizes downtime and equipment failure, supporting continuous operations.

Cost-Effective

Feature: Durable and low-maintenance design.

Advantage: Reduces maintenance costs and the need for frequent replacements, offering long-term savings.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430