Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGECEWÖU 3.6/6kV and 6/10kV Submersible Cable

(N)TSCGECEWÖU 3.6/6kV and 6/10kV Submersible Cables: Engineered for Extreme Underwater Conditions

(N)TSCGECEWÖU - 3.6/6kV and 6/10kV Submersible Cable

Application | Flexible supply cable for permanent immersion in salty and brackish water up to 300 meters under high mechanical stresses. Suitable for pumps, dredgers, floating docks, and trailing operations of opencast mining equipment. Suitable for indoor and outdoor applications. |

Voltage Rating Uo/U | 3.6/6kV, 6/10kV |

Test Voltage | 3.6/6kV: 11kV; 6/10kV: 17kV |

Ambient Temperature | Fixed: -40°C to +80°C; Flexed: -25°C to +60°C |

Maximum Permissible Water Temperature | +40°C |

Minimum Bending Radius | Fixed: 6 x overall diameter; Flexed: 10 x overall diameter |

Submersible Depth | 300 meters |

Phase Conductor | Class 5 tinned copper conductor |

Insulation | Rubber compound |

Semi-Conductive Layers | Semi-conductive tape over the conductor and inner/outer semi-conductive rubber layer on the insulation |

Protective Earth Conductor | Individual copper wire braid |

Central Filler | Rubber compound on a textile polyester support |

Inner Sheath | EPR rubber compound with waterproofing |

Outer Sheath | CM rubber compound with waterproofing |

Sheath Colour | Black |

Standards | VDE 0250 Part 813, VDE 0295, EN 60228 |

Flame Retardant | According to IEC/EN 60332-1-2 |

Introduction

In the shadowy depths of oceans, rivers, and flooded mine shafts, where human access is impossible and environmental pressures are unrelenting, a silent revolution powers critical operations. Enter the (N)TSCGECEWÖU submersible cables—specialized medium-voltage power lines designed for permanent immersion in harsh aquatic environments. Rated at 3.6/6kV and 6/10kV, these cables are the backbone of industries like opencast mining, dredging, and offshore pumping, ensuring reliable electricity delivery up to 300 meters underwater.

These aren't your everyday electrical wires. Constructed with class 5 tinned copper conductors, EPR (ethylene propylene rubber) insulation, and robust CM rubber sheaths, (N)TSCGECEWÖU submersible cables withstand salty and brackish water, high mechanical stresses, and temperatures from -40°C to +80°C. Compliant with standards like VDE 0250 Part 813 and flame-retardant per IEC/EN 60332-1-2, they represent a pinnacle of cable technology tailored for "trailing operations" in dynamic settings.

But why do these cables matter? In an era of resource scarcity and climate challenges, submersible infrastructure is key to sustainable extraction and water management. This article delves deep into their technical specifications, uncovers their multifaceted benefits, outlines prime usage scenarios, and presents a compelling case study from South Africa's mining sector. By the end, you'll appreciate how these unassuming cables fuel the engines of progress beneath the waves.

Why (N)TSCGECEWÖU Submersible Cables Outshine the Competition

In the brutal arena of subsea power transmission, (N)TSCGECEWÖU 3.6/6kV and 6/10kV submersible cables excel through a blend of innovation and practicality. First, their waterproofing—via EPR inner and CM outer sheaths—creates a multi-barrier seal against hydrostatic pressure and saline corrosion, extending lifespan by 2-3 times over standard cables.

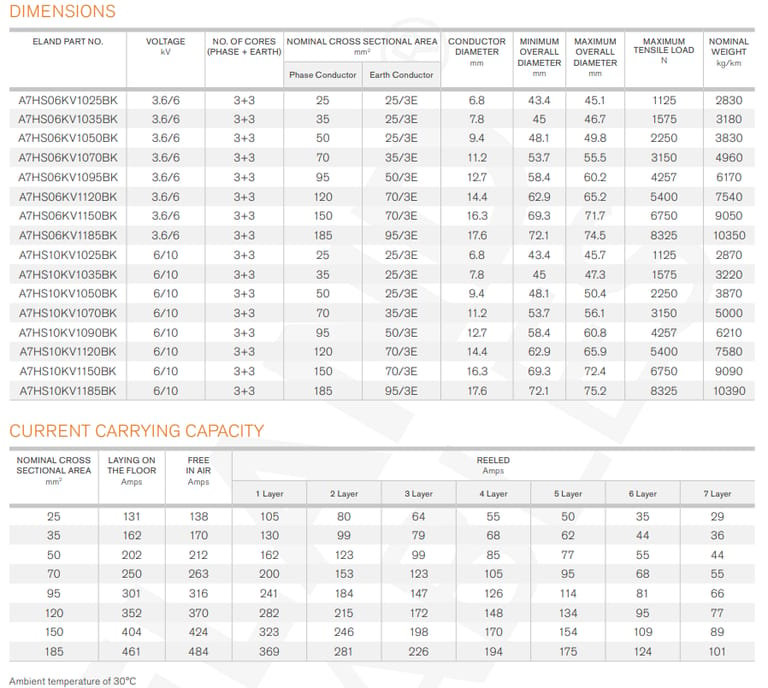

Mechanical toughness is another hallmark. The tinned copper braids and rubber fillers absorb shocks from dredging drags or pump vibrations, with tensile loads up to 8325N for larger sizes. This flexibility (class 5 stranding) suits trailing in opencast mining, reducing fatigue failures common in rigid alternatives.

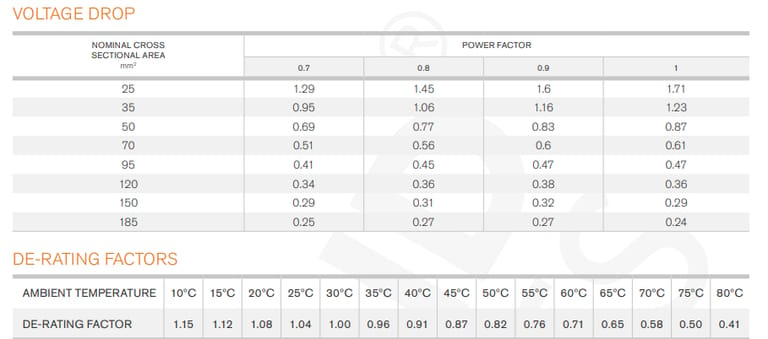

Electrically, semi-conductive layers uniformize electric fields, slashing insulation breakdown risks in conductive water. Flame retardancy per IEC/EN 60332-1-2 adds safety for indoor/outdoor use, while low voltage drop (under 2% for most runs) maintains efficiency, cutting energy losses by up to 15%.

Environmentally, these cables support green initiatives: recyclable materials and lead-free construction align with EU RoHS directives. In cost terms, their durability lowers total ownership costs—fewer replacements mean less downtime in high-stakes sectors.

Compared to generic submersible cables, (N)TSCGECEWÖU's VDE/EN compliance guarantees interoperability, while the 300m depth rating opens deep-water niches. Benefits compound: safer (earth braids prevent shocks), scalable (from 25-185 mm²), and versatile across voltages.

Usage Scenarios:

(N)TSCGECEWÖU submersible cables thrive where power meets peril. In opencast mining, they're trailed behind excavators in flooded pits, supplying 3.6/6kV to submersible pumps that dewater sites—essential in regions like Australia's outback or South Africa's Witwatersrand.

Dredging operations harness their 6/10kV rating for floating docks and cutter-suction dredgers, powering winches and thrusters in brackish harbors. Up to 484A capacity supports heavy loads, with 10x bending radius allowing dynamic reeling without kinks.

Offshore pumps for oil/gas or aquaculture use them for permanent immersion, feeding electricity to ESPs (electrical submersible pumps) in wells. Indoor factories with wet processes—think food processing or wastewater treatment—benefit from their -40°C cold flexibility.

In emergency scenarios, like flood control, these cables link portable generators to submersible motors, enduring +80°C heat from friction. Their black sheath camouflages in dark waters, aiding marine life camouflage, while lightweight designs (under 11,000 kg/km) ease deployment. From salty Baltic ports to acidic mine sumps, these cables adapt seamlessly.

The (N)TSCGECEWÖU 3.6/6kV and 6/10kV submersible cables are more than mere conduits—they're lifelines for industries grappling with aqueous extremes. From their meticulously engineered specs—class 5 tinned copper, EPR insulation, and robust sheathing—to benefits like corrosion resistance and low voltage drop, these cables empower pumps, dredgers, and miners worldwide.

In South Africa's Johannesburg case, they didn't just transmit power; they resurrected a faltering economy, dewatering toxic floods to unlock golden opportunities. As climate change intensifies flooding and deepens mining needs, demand for such tech surges—projected 8% CAGR through 2030.

Yet, challenges remain: scaling for gigawatt renewables or bio-mimetic designs for less ecological impact. Innovations like embedded sensors for real-time monitoring could elevate them further. Ultimately, (N)TSCGECEWÖU submersible cables remind us: in the depths, reliability isn't optional—it's elemental. By harnessing their power, we not only conquer the waves but sustain the world above.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430