Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGECEWÖU - 8.7/15kV and 12/20kV Submersible Cable

(N)TSCGECEWÖU - 8.7/15kV and 12/20kV Submersible Cable

APPLICATION | Flexible supply cable for permanent immersion in salty and brackish water up to 300 m under high mechanical stress. Used in pumps, dredges, floating docks, and suitable for trailing operations of opencast mining equipment. Applicable for indoor and outdoor use. |

CHARACTERISTICS | Voltage Rating (Uo/U): 8.7/15 kV, 12/20 kV Test Voltage: 24 kV (8.7/15 kV), 29 kV (12/20 kV) Ambient Temperature: Fixed: -40°C to +80°C; Flexed: -25°C to +60°C Minimum Bending Radius: Fixed: 6 × overall diameter; Flexed: 10 × overall diameter Submersible Depth: 300 m |

CONSTRUCTION | Phase Conductor: Class 5 tinned copper conductor Insulation: Rubber compound Semi-Conductive Layers: Semi-conductive tape over conductor; inner and outer semi-conductive rubber layer on insulation Protective Earth Conductor: Individual copper wire braid Central Filler: Rubber compound on textile polyester support Inner Sheath: EPR rubber compound with waterproofing Outer Sheath: CM rubber compound with waterproofing Sheath Colour: Black |

STANDARDS | VDE 0250 Part 813, VDE 0295, EN 60228 Flame Retardant according to IEC/EN 60332-1-2 |

Introduction

Cables are the invisible lifelines of modern industry. In harsh and demanding environments such as open-pit mines, dredging operations, offshore platforms, and underwater pumping systems, the reliability of a power cable directly influences safety, productivity, and equipment performance. Among the most advanced solutions for these conditions are (N)TSCGECEWÖU submersible cables, rated for 8.7/15kV and 12/20kV applications.

These cables are engineered to operate under high mechanical stress, deep-water immersion up to 300 metres, and extreme temperature ranges. Their construction, based on tinned copper conductors, robust rubber insulation, and multiple layers of water-proofing sheaths, ensures durability, flexibility, and compliance with stringent standards such as VDE 0250 Part 813 and IEC/EN 60332-1-2 for flame retardancy.

Benefits of (N)TSCGECEWÖU Submersible Cables

High Voltage and Power Handling

Capable of transmitting substantial power over long distances in submerged and high-stress environments.Corrosion Resistance

Tinned copper conductors prevent electrochemical degradation in salty or brackish water.Mechanical Strength

Designed for trailing operations, resisting abrasion, crushing, and repeated flexing.Thermal Endurance

Wide operating temperature range allows global application, from cold storage docks to desert-based mining.Safety Compliance

Flame retardancy and strong earth conductor braiding enhance workplace safety.Versatility

Suitable for indoor, outdoor, underwater, and mobile applications.

Usage Scenarios

1. Mining Industry

Open-cast Mining Equipment: For powering electrically driven excavators, drills, and mobile pumps.

Underground Pumps: Reliable power in high groundwater environments.

2. Marine and Offshore Applications

Dredging Equipment: Continuous power supply to dredge pumps working below water.

Floating Docks: Electrical systems for submerged or semi-submerged platforms.

3. Water Management Systems

Submersible Pumps: For desalination plants, irrigation systems, and sewage treatment facilities.

4. Industrial and Energy Applications

Hydropower Stations: Power supply to submerged turbines or pumps.

Oil & Gas: Offshore rigs and refineries where cables must operate underwater.

Frequently Asked Questions (FAQ)

Q1: Can (N)TSCGECEWÖU cables be permanently submerged?

Yes. They are designed for continuous operation up to 300 metres underwater, in both salty and brackish water.

Q2: What makes these cables different from standard rubber-insulated cables?

Their multi-layered construction, semi-conductive shielding, and water-blocking compounds make them uniquely suited for high-voltage, submerged, and mechanically demanding environments.

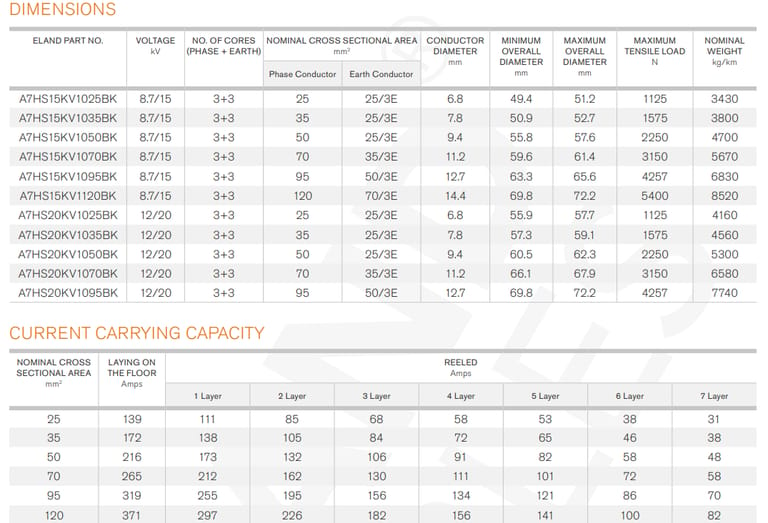

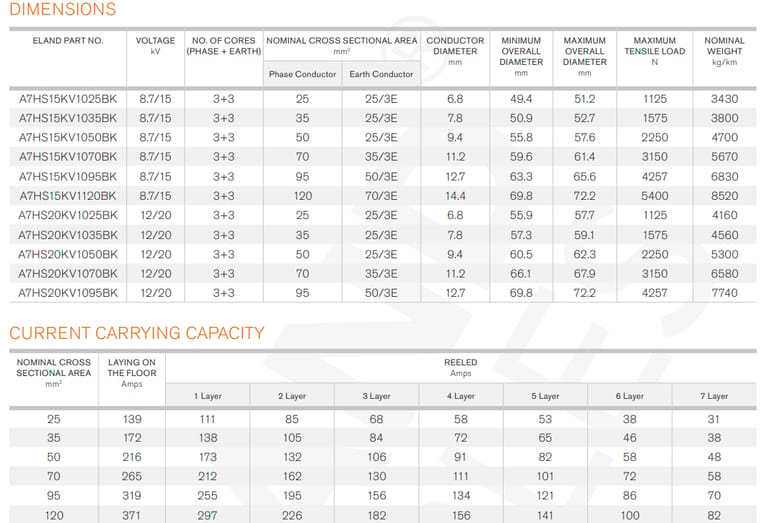

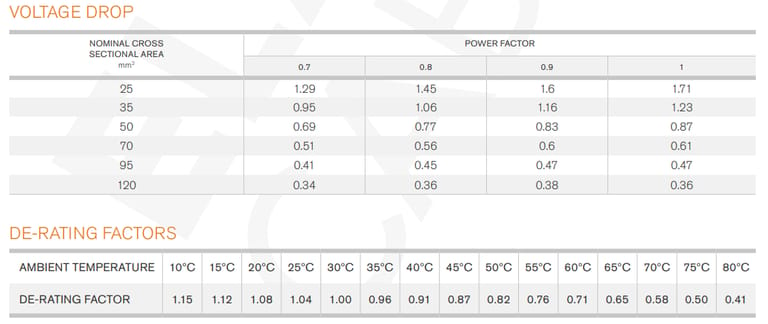

Q3: How do they perform under reeling conditions?

They maintain high current capacity but derating occurs with multiple layers of reeling. Correct drum design and installation reduce losses.

Q4: Are they suitable for extreme climates?

Yes. With a fixed temperature range of –40°C to +80°C, they can operate in cold northern climates and hot desert mines.

Q5: Do they meet international safety standards?

Absolutely. They comply with VDE, EN, and IEC standards, including flame retardancy and conductor specifications.

The (N)TSCGECEWÖU 8.7/15kV and 12/20kV submersible cables are more than just high-voltage conductors—they are lifelines that enable safe and efficient operation in mining, dredging, offshore, and industrial applications. Their unique construction ensures waterproofing, flexibility, mechanical strength, and long-term durability in environments where failure is not an option.

As demonstrated in the South African case study, these cables not only ensure continuous operations but also improve safety and cost efficiency in industries where both are critical.

For organisations operating in demanding underwater or high-stress environments, investing in (N)TSCGECEWÖU submersible cables is not just a technical choice—it’s a strategic decision that safeguards people, equipment, and productivity.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430