Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTSCGECWOEU Medium-Voltage Coal Cutter Cable VDE 0250 Part 813

Discover the role of NTSCGECWOEU medium-voltage coal cutter cables in South African mining.

NTSCGECWOEU Medium-Voltage Coal Cutter Cable VDE 0250 Part 813

Applications | These cables are used for the connection of mobile electrical equipment inunderground mines, e.g. for coal-cutting machines,especially for the use in battery chains with extremebending loads under low tensile stress. |

Standards | VDE 0250 Part 813 |

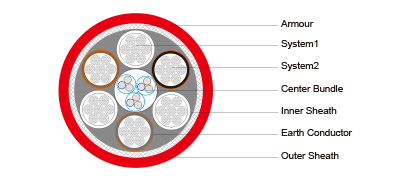

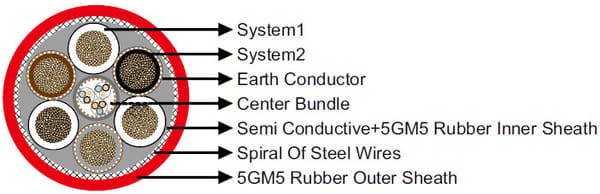

Construction  | |

System1 (1.8/3kV or 3.6/6kV) | Flexible stranded tinned copper conductor with heatresistant3GI3 rubber based on EPR,easy strippable outer conductive layer. |

System2 (0.6/1kV) | Flexible stranded tinned copper conductor with heatresistant3GI3 rubber based on EPR. |

Earth Conductor | Spiral of tinnedcopper. |

Center Bundle | Control and pilot cores withcopper/steel conductors capable of expansion andcompression, EPR insulation,optional with fiber optics, covered with tinned copper wires semi conductive rubber sheath. |

InnerSheath | 2 layer design, semi conductive rubber + Rubber type 5GM5. |

Armour | Spiral of steel wires,embedded in the outer sheath, fiberglas tape which preventssheath exchanging. |

Outer Sheath | Rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

1.8/3kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×50+3×(35+35/3)+2×(2×0.75ST)+2×0.75 | 62.0 | 66.0 | 7210 |

3×70+3×(50+50/3)+2×(2×0.75ST)+2×0.75 | 64.0 | 68.0 | 8200 |

3×95+3×(70+70/3)+2×(2×0.75ST)+2×0.75 | 74.0 | 78.0 | 10300 |

3.6/6kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×35+3×(35+35/3)+2×(2×0.75ST)+2×0.75 | 66.0 | 72.0 | 7600 |

3×50+3×(50+50/3)+2×(2×0.75ST)+2×0.75 | 69.0 | 75.0 | 9200 |

3×70+3×(70+70/3)+2×(2×0.75ST)+2×0.75 | 76.0 | 81.0 | 11150 |

3×95+3×(95+95/3)+2×(2×0.75ST)+2×0.75 | 85.0 | 90.0 | 13300 |

What Are Medium-Voltage Coal Cutter Cables?

Medium-voltage coal cutter cables, such as the NTSCGECWOEU, are engineered to deliver power to mobile electrical equipment in underground mining environments. These cables are designed to withstand the harsh conditions of mines, including abrasion, oil exposure, and extreme bending loads. They are typically used in applications like coal-cutting machines and battery chains, where flexibility and resilience are essential.

Key Features

Voltage Ratings: Available in 1.8/3kV and 3.6/6kV configurations for medium-voltage applications.

Construction: Comprises flexible stranded tinned copper conductors, heat-resistant EPR (ethylene propylene rubber) insulation, and a robust outer sheath.

Durability: Abrasion-resistant, tear-resistant, oil-resistant, and flame-retardant properties ensure longevity.

Flexibility: Designed for extreme bending under low tensile stress, ideal for dynamic mining operations.

Benefits of NTSCGECWOEU Cables

The NTSCGECWOEU cable offers several advantages that make it a preferred choice for mining operations:

Durability: The abrasion-resistant and tear-resistant outer sheath ensures the cable can withstand the physical stresses of underground mining.

Flexibility: Designed for extreme bending, the cable maintains performance in dynamic applications like coal-cutting machines.

Safety: Flame-retardant and oil-resistant properties reduce the risk of fire and chemical degradation.

Reliability: The use of tinned copper conductors and EPR insulation ensures consistent power delivery and heat resistance.

Versatility: Optional fiber optics in the center bundle enable advanced monitoring and communication capabilities.

Installation Recommendations

Proper installation of medium-voltage coal cutter cables is critical to ensure safety and performance. Here are key guidelines:

Pre-Installation Inspection: Check for physical damage, such as cuts or abrasions, before installation. Verify that the cable matches the required voltage and core configuration.

Routing: Avoid sharp bends or excessive tension during installation. Use cable guides or rollers to minimize stress on the cable.

Environmental Considerations: Ensure the cable is protected from excessive moisture, chemicals, and extreme temperatures during installation.

Grounding: Properly connect the earth conductor to the grounding system to prevent electrical faults.

Securing: Use appropriate clamps and supports to secure the cable, preventing movement that could lead to wear or damage.

Maintenance Recommendations

Regular maintenance extends the lifespan of NTSCGECWOEU cables and ensures operational safety:

Visual Inspections: Routinely check for signs of wear, such as abrasions, cuts, or exposed conductors.

Cleaning: Remove dust, coal particles, or chemical residues from the outer sheath to prevent degradation.

Electrical Testing: Periodically test insulation resistance and continuity to detect potential faults.

Replacement: Replace cables showing significant wear or damage to avoid unexpected failures.

Storage: Store spare cables in a dry, cool environment to prevent degradation of the rubber sheath.

Usage Scenarios in South African Mining

South Africa’s mining industry, a cornerstone of the economy, relies heavily on robust infrastructure to maintain productivity and safety. Medium-voltage coal cutter cables like the NTSCGECWOEU are integral to powering heavy machinery in coal, gold, and platinum mines.

Case Study : Supporting Deep-Level Mining in Gauteng

A gold mine in Gauteng, operating at depths exceeding 3 kilometers, required cables capable of withstanding extreme bending and low tensile stress. The NTSCGECWOEU 3.6/6kV cables were deployed to power advanced coal-cutting machines. Their flexibility and robust construction reduced maintenance costs by 25% compared to previous cables, while the steel wire armour provided additional protection against rockfalls, a common hazard in deep-level mining.

The NTSCGECWOEU medium-voltage coal cutter cable is a vital component in South Africa’s mining industry, offering unmatched durability, flexibility, and safety. Its technical specifications, including tinned copper conductors, EPR insulation, and flame-retardant sheaths, make it ideal for powering coal-cutting machines in harsh underground environments. Through proper installation and maintenance, these cables ensure reliable performance, as demonstrated in case studies from KwaZulu-Natal and Gauteng. As South Africa’s mining sector embraces automation and safety innovations, cables like the NTSCGECWOEU will continue to play a pivotal role in driving efficiency and protecting workers.

For mining companies seeking to enhance operational reliability, investing in high-quality medium-voltage coal cutter cables is a strategic choice that delivers both immediate and long-term benefits.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430