Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGECWOEU Medium-Voltage Trailing Cable VDE 0250 Part 813

A Comprehensive Guide to (N)TSCGECWOEU Medium-Voltage Trailing Cable

(N)TSCGECWOEU Medium-Voltage Trailing Cable VDE 0250 Part 813

Applications | These cables are used for the connection of electrical equipment, in minesand underground excavations with hazardousenvironments under particularly high mechanical loads,e.g. high-voltage transformers on power lines inunderground mining and tunnelling. |

Standards | Based on VDE 0250 Part 813 |

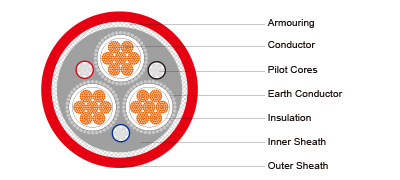

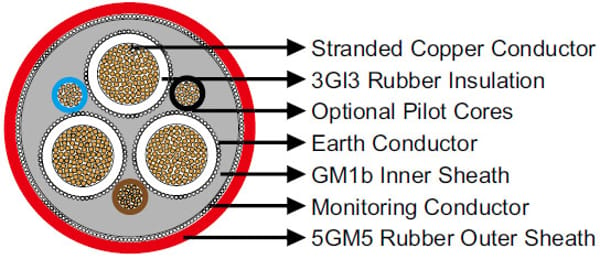

Construction  | |

Conductors | Flexible stranded copper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Special rubber compound, conductive. |

Insulation | Rubber type 3GI3. |

Outer Conductor Layer | Special rubber compound, conductive, easy strippable. |

Pilot Cores (optional) | Tinned copper conductor with EPR insulation. |

Earth Conductor | Spiral of tinnedcopper wires. |

InnerSheath | Rubber type GM1b. |

Monitoring Shield/Armour | Braided armour of combined copper-steel wires; or wrap of copper and steel wires, copper tape in opposite direction, reinforcing tape. |

Outer Sheath | Rubber type 5GM5. |

Dimensions and Weight

6/10kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×16/3E+3×2.5ST+6UEL | 48 | 52 | 3500 |

3×35+3×16/3E+3×2.5ST+6UEL | 51 | 55 | 3750 |

3×50+3×25/3E+3×2.5ST+6UEL | 56 | 60 | 4720 |

3×95+3×50/3E+3×2.5ST+6UEL | 66 | 71 | 7260 |

3×120+3×70/3E+6UEL | 70 | 75 | 9700 |

3×150+3×70/3E+6UEL | 73 | 78 | 9950 |

12/20 (24) kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3E+6UEL | 62 | 67 | 5800 |

3×95+3×50/3E+6UEL | 74 | 78 | 11000 |

3×120+3×70/3E+6UEL | 80 | 85 | 13000 |

Why Medium-Voltage Trailing Cables Matter in Modern Mining

South Africa’s mining industry has always been a cornerstone of its economy, driving global demand for commodities such as gold, platinum, coal, and manganese. To sustain such massive operations, mines require reliable electrical power systems that can withstand extreme environments. One of the most crucial components in this infrastructure is the medium-voltage trailing cable, specifically designed to deliver electricity to moving equipment such as mining excavators, drilling rigs, and high-voltage transformers.

Among the most advanced cable types in this category is the (N)TSCGECWOEU medium-voltage trailing cable, a robust design based on VDE 0250 Part 813 standards. With its combination of flexibility, mechanical resilience, and electrical reliability, it has become a preferred choice in hazardous mining and tunnelling environments worldwide — including South Africa.

Cable Overview and Standards

The (N)TSCGECWOEU cable is specifically designed for connection of electrical equipment in underground mining and tunnelling environments, where it must endure:

Extreme mechanical stress such as bending, crushing, and pulling.

Hazardous conditions like explosive atmospheres, oil exposure, and abrasion.

Continuous movement, since trailing cables must follow equipment without failure.

It complies with VDE 0250 Part 813, a German standard that defines requirements for flexible cables used in mining and similar heavy-duty applications. While this is a European standard, it aligns closely with SANS 1520-1 in South Africa, making the cable suitable for compliance under local regulatory frameworks.

Benefits of (N)TSCGECWOEU Cables

Mining operators face increasing pressure to balance safety, cost-efficiency, and operational uptime. The (N)TSCGECWOEU cable provides several benefits that address these challenges:

Mechanical Durability: With armour and reinforced sheathing, it resists crushing, tearing, and impact.

Flexibility: Class 5 copper ensures repeated bending without conductor fatigue.

Safety: Flame-retardant, oil-resistant, and compliant with international safety standards.

Monitoring Capability: Optional pilot cores and monitoring shields allow real-time fault detection.

Long Service Life: Resistance to abrasion and environmental stress reduces replacement frequency.

Installation and Maintenance Recommendations

Proper installation and maintenance are key to maximising cable performance.

Installation Tips:

Avoid sharp bending radii; follow manufacturer’s minimum bending requirements.

Use appropriate cable reels to prevent twisting or kinking.

Ensure proper grounding of earth conductors.

Protect cable ends from moisture ingress during storage and handling.

Maintenance Best Practices:

Conduct regular visual inspections for cuts, abrasions, and deformation.

Test insulation resistance periodically.

Monitor shield integrity to detect early-stage faults.

Replace cable segments showing excessive wear before failure occurs.

Application Scenarios

The (N)TSCGECWOEU cable is most commonly used in:

Underground Mining: Powering drilling rigs, shuttle cars, and high-voltage transformers.

Tunnelling Projects: Supplying mobile machinery in excavation sites.

Heavy Industry: For applications requiring mobile power distribution under harsh conditions.

Hazardous Environments: Locations with oil, moisture, or fire risks.

Case Studies: South African Mining Applications

Case Study 1: Gold Mining in Gauteng

In South Africa’s Gauteng Province, a deep-level gold mine introduced 12/20kV (N)TSCGECWOEU cables to replace older trailing cables. The mine reported:

A 30% reduction in cable failure incidents, leading to less downtime.

Improved monitoring via pilot cores, enabling predictive maintenance.

Significant savings in cable replacement costs.

Case Study 2: Platinum Mining in Limpopo

A platinum mine in Limpopo deployed 6/10kV versions of the cable for mobile transformers and drill rigs. Results included:

Enhanced safety compliance with NRCS standards.

Extended service life despite exposure to wet, abrasive tunnel conditions.

Greater flexibility for mobile equipment without risking conductor fatigue.

Case Study 3: Renewable Energy in Mining

As South Africa invests in hybrid renewable-diesel power systems for mines, medium-voltage trailing cables like (N)TSCGECWOEU are increasingly used to connect mobile solar-diesel power stations. These setups require flexible yet robust cables to handle frequent repositioning.

The (N)TSCGECWOEU medium-voltage trailing cable represents the future of safe, durable, and efficient power distribution in mining and heavy industry. Its advanced design — combining mechanical strength, flexibility, monitoring capabilities, and compliance with international standards — makes it an invaluable asset for South African mining operations striving to improve uptime, safety, and sustainability.

By adopting such high-performance cables and following proper installation and maintenance practices, mining companies can achieve not only operational efficiency but also long-term cost savings and regulatory compliance.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430