Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTSCGERLWOEU 3.6/6kV Flexible Submersible Cable VDE 0250 Part 813

Introduction to NTSCGERLWOEU 3.6/6 KV Flexible Submersible Cable

NTSCGERLWOEU 3.6/6kV Flexible Submersible Cable VDE 0250 Part 813

Applications | These cables are used for permanent operation inwater where the cable is required to have additional mechanical protection. |

Standards | VDE 0250 Part 813 |

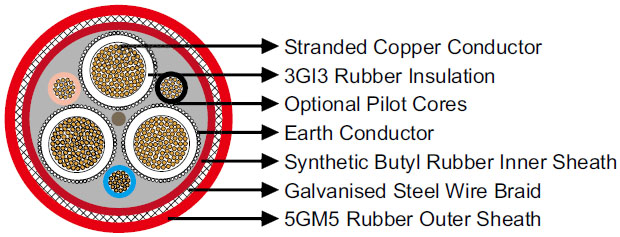

Construction  | |

Conductors | Flexible stranded tinned copper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Special rubber compound, conductive. |

Insulation | Rubbertype 3GI3. |

Outer Conductor Layer | Special rubber, conductive, easy strippable. |

Pilot Cores (optional) | Copper conductor with EPR insulation. |

Earth Conductor | Spiral of tinned annealed copper wires. |

InnerSheath | Waterproof synthetic butyl rubber. |

Armouring | Braid of galvanised steel strands. |

Outer Sheath | Rubber type 5GM5. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×35+3×16/3E | 55.0 | 60.0 | 4600 |

3×50+3×25/3E | 59.0 | 67.0 | 5600 |

3×70+3×35/3E | 64.0 | 70.0 | 6700 |

3×95+3×50/3E | 68.0 | 75.0 | 7900 |

3×120+3×70/3E | 75.0 | 80.0 | 9980 |

In modern mining and heavy industry, power transmission is not just about carrying electricity—it is about ensuring safety, reliability, and durability in some of the harshest environments on earth. Nowhere is this more evident than in South Africa, where underground mining operations for gold, platinum, manganese, and coal rely heavily on submersible cables to power pumps, dewatering systems, and mobile equipment in water-filled shafts and tunnels.

One of the most advanced solutions for such environments is the NTSCGERLWOEU 3.6/6kV Flexible Submersible Cable, a specialized cable designed under VDE 0250 Part 813 standards. Built with a robust structure, superior insulation, and enhanced mechanical protection, it ensures reliable operation under continuous submersion and extreme mechanical stress.

What is the NTSCGERLWOEU 3.6/6kV Flexible Submersible Cable?

The NTSCGERLWOEU is a medium-voltage flexible power cable specifically designed for:

Permanent operation in water (submersible applications).

Situations requiring extra mechanical protection against abrasion, crushing, and tension.

Environments with electrical, thermal, and chemical stress.

Its 3.6/6kV rating allows it to deliver stable medium-voltage power to pumps, drilling equipment, and mobile mining machinery, even when exposed to water, mud, or mechanical impacts.

Benefits of NTSCGERLWOEU Flexible Submersible Cables

Reliability Underwater: With a waterproof sheath and armour, it performs consistently under long-term water exposure.

Mechanical Durability: Steel braid armouring prevents crushing in shafts or tunnels.

Flexibility: Despite its strength, the cable remains flexible, allowing easier installation.

Corrosion Resistance: Tinned copper conductors protect against oxidation in humid and chemical-rich environments.

Safety Assurance: Integrated earth conductor and grounding layers ensure operator and equipment safety.

Versatility: Suitable for both fixed and mobile submersible mining equipment.

Usage Scenarios

1. South African Mining – Dewatering Systems

Mines in the Witwatersrand Basin (gold) and Bushveld Complex (platinum) frequently struggle with groundwater flooding. Submersible pumps powered by NTSCGERLWOEU cables keep shafts dry and safe.

2. Coal Mines in Mpumalanga

Submersible cables are essential in Mpumalanga coal mines, where underground water must be pumped out continuously to prevent operational delays and hazards.

3. Heavy Industry and Tunneling

In infrastructure projects, such as tunnel boring under Johannesburg, flexible submersible cables provide power to slurry pumps and drilling rigs.

The NTSCGERLWOEU 3.6/6kV Flexible Submersible Cable is not just a technical product—it is a lifeline for mining and heavy industry operations, particularly in South Africa. By offering robust waterproofing, mechanical durability, electrical safety, and compliance with international standards, it plays a critical role in ensuring uninterrupted operations in environments where failure is not an option.

From flooded shafts in Rustenburg to coal mines in Mpumalanga, these cables demonstrate how engineering innovation directly supports economic and industrial resilience. For companies seeking safety, efficiency, and long-term reliability, the NTSCGERLWOEU remains one of the most advanced solutions available today.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430