Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTSCGEWOEU Flexible Medium-Voltage Trailing Cable VDE 0250 Part 813

Comprehensive Guide to NTSCGEWOEU Flexible Medium-Voltage Trailing Cables for High-Stress Mining Operations and Heavy Industrial Applications in South Africa

NTSCGEWOEU Flexible Medium-Voltage Trailing Cable VDE 0250 Part 813

Applications | These cables are used as power supply or connection cables for large material handling machines, e.g. excavators in open-cast mines subject to extremely high mechanical stresses. Particularly suitable for applications in which abrasion and chaffing stresses are to be expected in trailing operation. |

Standards | VDE 0250 Part 813 |

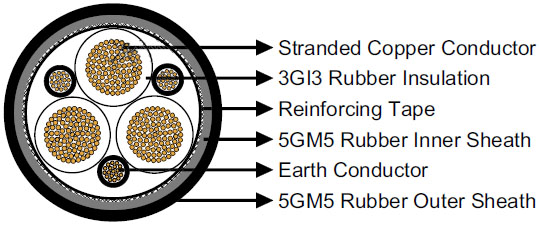

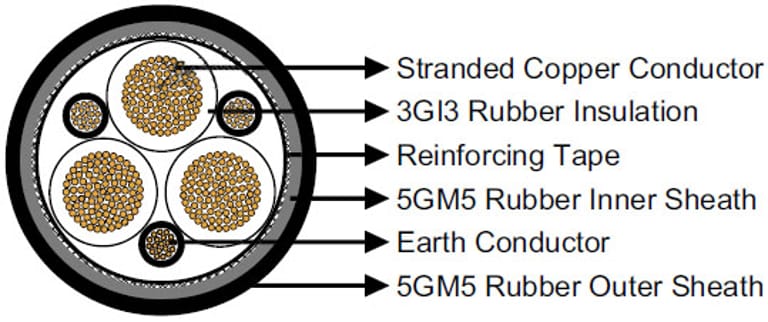

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Semiconductive layer. |

Insulation | Rubber type 3GI3. |

Outer Conductor Layer | Semiconductive layer. |

Earth Conductor | Split into three in theouter interstices or Individual concentric distributed over core insulating coverings (coding…../3E). |

Reinforcing Tape | Extremely tear-resistant reinforcing tape. |

InnerSheath | Rubber type 5GM5, abrasion and tear resistant, oil and ozone resistant. |

Outer Sheath | Rubber type 5GM5, abrasion and tear resistant, oil and ozone resistant, inseparably bonded with inner sheath. |

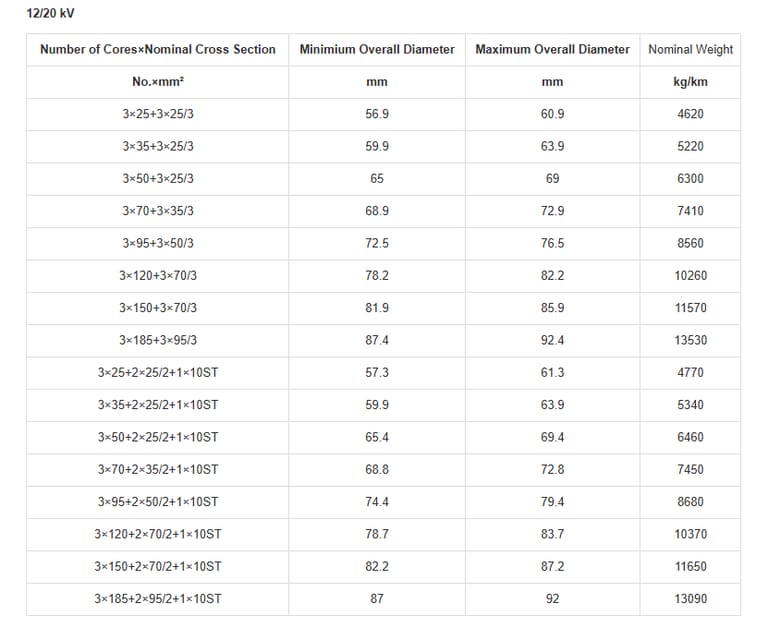

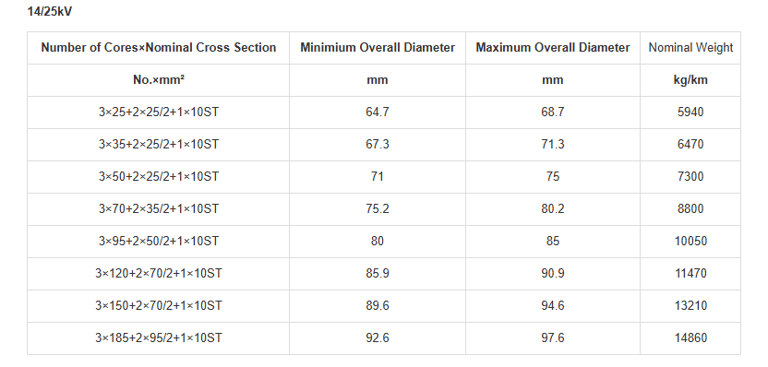

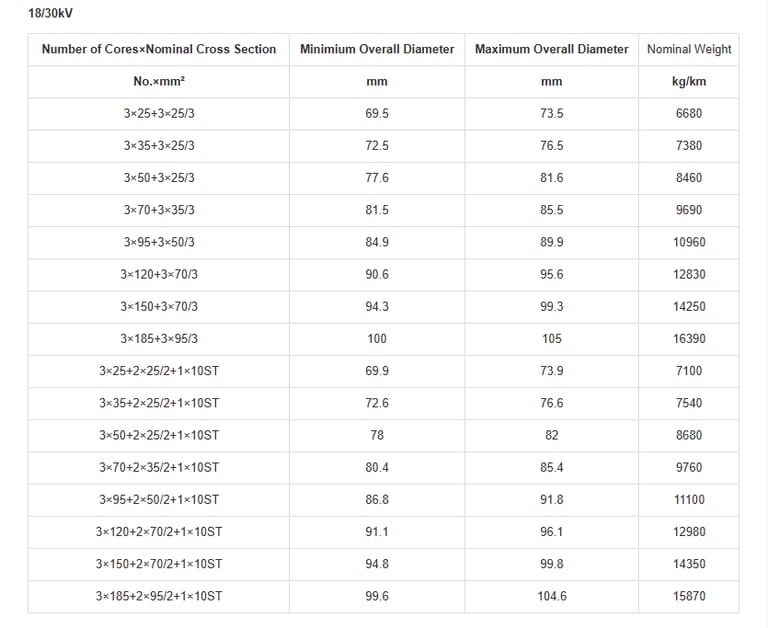

Dimensions and Weight

1.8/3kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 38.5 | 41.5 | 2470 |

3×35+3×25/3 | 42.9 | 45.9 | 3080 |

3×50+3×25/3 | 46.1 | 49.1 | 3750 |

3×70+3×35/3 | 49.7 | 53.7 | 4690 |

3×95+3×50/3 | 57.4 | 61.4 | 6210 |

3×120+3×70/3 | 61.2 | 65.2 | 7430 |

3×150+3×70/3 | 66.7 | 70.7 | 8900 |

3×185+3×95/3 | 70.6 | 74.6 | 10330 |

3×25+2×25/2+1×10ST | 40.3 | 44.3 | 2470 |

3×35+2×25/2+1×10ST | 42.9 | 46.9 | 3080 |

3×50+2×25/2+1×10ST | 46.8 | 50.8 | 3750 |

3×70+2×35/2+1×10ST | 51.5 | 55.5 | 4690 |

3×95+2×50/2+1×10ST | 57.4 | 62.4 | 6210 |

3×120+2×70/2+1×10ST | 63.6 | 68.6 | 7430 |

3×150+2×70/2+1×10ST | 67.2 | 72.2 | 8900 |

3×185+2×95/2+1×10ST | 70.2 | 75.2 | 10330 |

3.6/6kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 44.6 | 47.6 | 3080 |

3×35+3×25/3 | 47.6 | 50.6 | 3590 |

3×50+3×25/3 | 52.4 | 56.4 | 4520 |

3×70+3×35/3 | 56.3 | 60.3 | 5520 |

3×95+3×50/3 | 59.9 | 63.9 | 6580 |

3×120+3×70/3 | 65.6 | 69.6 | 8110 |

3×150+3×70/3 | 69.3 | 73.3 | 9320 |

3×185+3×95/3 | 73.2 | 77.2 | 10780 |

3×25+2×25/2+1×10ST | 45 | 49 | 3200 |

3×35+2×25/2+1×10ST | 47.6 | 51.6 | 3680 |

3×50+2×25/2+1×10ST | 53 | 57 | 4640 |

3×70+2×35/2+1×10ST | 56.2 | 60.2 | 5550 |

3×95+2×50/2+1×10ST | 61.8 | 66.8 | 6650 |

3×120+2×70/2+1×10ST | 66.1 | 71.1 | 8160 |

3×150+2×70/2+1×10ST | 69.8 | 74.8 | 9340 |

3×185+2×95/2+1×10ST | 74.6 | 79.6 | 10890 |

6/10 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 46.4 | 49.4 | 3270 |

3×35+3×25/3 | 49.1 | 53.1 | 3800 |

3×50+3×25/3 | 54.1 | 58.1 | 4750 |

3×70+3×35/3 | 58 | 62 | 5750 |

3×95+3×50/3 | 61.7 | 65.7 | 6830 |

3×120+3×70/3 | 67.4 | 71.4 | 8380 |

3×150+3×70/3 | 71 | 75 | 9620 |

3×185+3×95/3 | 76.7 | 80.7 | 11430 |

3×25+2×25/2+1×10ST | 46.8 | 50.8 | 3410 |

3×35+2×25/2+1×10ST | 50.9 | 54.9 | 3890 |

3×50+2×25/2+1×10ST | 54.5 | 58.9 | 4860 |

3×70+2×35/2+1×10ST | 58 | 62 | 5780 |

3×95+2×50/2+1×10ST | 63.5 | 68.5 | 6920 |

3×120+2×70/2+1×10ST | 67.8 | 72.8 | 8450 |

3×150+2×70/2+1×10ST | 71.5 | 76.5 | 9620 |

3×185+2×95/2+1×10ST | 76.3 | 81.3 | 10980 |

8.7/15 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 52.6 | 56.6 | 4040 |

3×35+3×25/3 | 55.6 | 59.6 | 4630 |

3×50+3×25/3 | 58.9 | 62.9 | 5370 |

3×70+3×35/3 | 64.5 | 68.5 | 6720 |

3×95+3×50/3 | 68.2 | 72.2 | 7850 |

3×120+3×70/3 | 72.1 | 76.1 | 9130 |

3×150+3×70/3 | 77.6 | 81.6 | 10750 |

3×185+3×95/3 | 81.5 | 85.5 | 12290 |

3×25+2×25/2+1×10ST | 53 | 57 | 4130 |

3×35+2×25/2+1×10ST | 55.6 | 59.6 | 4740 |

3×50+2×25/2+1×10ST | 59.3 | 63.3 | 5470 |

3×70+2×35/2+1×10ST | 64.6 | 68.6 | 6820 |

3×95+2×50/2+1×10ST | 68.3 | 73.3 | 7950 |

3×120+2×70/2+1×10ST | 74.4 | 79.4 | 9240 |

3×150+2×70/2+1×10ST | 78.1 | 83.1 | 10860 |

3×185+2×95/2+1×10ST | 81.1 | 86.1 | 12400 |

In South Africa’s mining and heavy industrial sectors, ensuring the safe and reliable supply of power to large mobile machinery is crucial. Excavators, draglines, and other material-handling equipment in open-cast mines are subjected to extreme mechanical stresses, abrasion, and chafing during operation. NTSCGEWOEU flexible medium-voltage trailing cables, compliant with VDE 0250 Part 813, are engineered to meet these demanding conditions.

Understanding NTSCGEWOEU Flexible Medium-Voltage Trailing Cables

Cable Purpose:

NTSCGEWOEU cables are primarily used as power supply or connection cables for large material-handling machines such as excavators in open-cast mines. They are particularly effective in operations where mechanical abrasion and chafing are common, making them suitable for trailing applications where cables experience repeated motion.

Standards Compliance:

These cables adhere to VDE 0250 Part 813, ensuring quality and safety standards for medium-voltage flexible trailing cables. Compliance with this standard guarantees reliable performance even under challenging mechanical and environmental conditions.

Benefits of NTSCGEWOEU Cables

1. Mechanical Durability:

The bonded inner and outer sheaths, reinforced tape, and flexible copper conductors ensure resistance against tearing, abrasion, and repeated bending, which is vital for mining operations where cables are dragged, pulled, or rolled.

2. Electrical Reliability:

Semiconductive layers and high-quality rubber insulation maintain performance under medium-voltage conditions, ensuring minimal electrical losses and consistent power delivery.

3. Environmental Resistance:

Rubber sheaths are resistant to oils, ozone, and extreme temperatures, providing long service life in harsh mining environments.

4. Safety Compliance:

Conformance to VDE 0250 Part 813 ensures adherence to international electrical and safety standards, minimizing operational risks.

5. Flexible Design:

Flexible conductors allow easier installation and handling around moving equipment, reducing downtime during cable replacement or repositioning.

Usage Scenarios

1. Open-Cast Mining Excavators:

NTSCGEWOEU cables are ideal for draglines and bucket-wheel excavators, which operate continuously and require long, flexible power connections.

2. Heavy Material Handling:

Cranes, stackers, and reclaimers in mining and ports can benefit from flexible trailing cables capable of withstanding abrasion and repetitive motion.

3. Industrial Automation:

Factories handling bulk materials or high-capacity conveyors can deploy these cables in areas subject to mechanical stress and oil exposure.

Case Study – South African Mining Application:

A platinum mine in the Rustenburg area replaced traditional rigid medium-voltage cables with NTSCGEWOEU trailing cables on a fleet of large excavators. The result was a 50% reduction in cable replacement frequency, improved operational uptime, and safer handling due to flexible conductors.

NTSCGEWOEU flexible medium-voltage trailing cables represent an essential component in South Africa’s mining and heavy industry sectors. Engineered for extreme mechanical stress, abrasion, and environmental challenges, they combine flexibility, durability, and electrical reliability. By understanding cable construction, specifications, installation practices, and maintenance strategies, operators can optimize uptime, enhance safety, and achieve long-term operational efficiency.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430