Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGEWOEU Medium-Voltage Fixed Installation Cable With Fiber Optics

Why (N)TSCGEWOEU Medium-Voltage Fixed Installation Cable with Fiber Optics Is Transforming Mining and Heavy Industry Applications in South Africa

(N)TSCGEWOEU Medium-Voltage Fixed Installation Cable With Fiber Optics

Applications | These cables are used for For laying alongside the conveyor belts (also for shiftable units)and on material handling equipment (even with continuous movementsuch as in cable booms or as connection between upperand lower car) and for connection of submersible pump units. |

Standards | Based on VDE 0250 Part 813 |

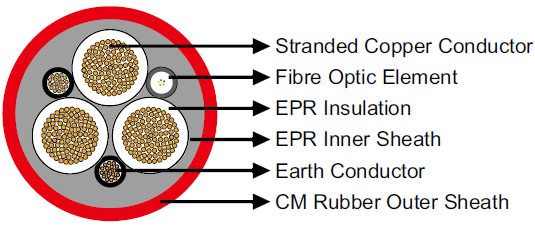

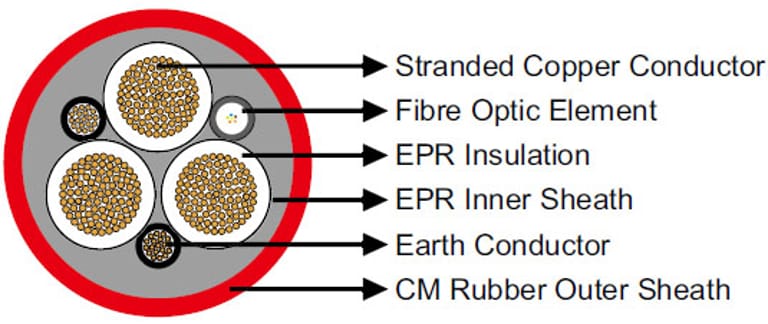

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Semiconductive layer. |

Insulation | EPR. |

Outer Conductor Layer | Semiconductive layer. |

Earth Conductor | Split into two in the outer interstices. |

Fiber Optics | FO 50/125 or 62.5/125 orE9/125μm within protection sheath. |

InnerSheath | EPR. |

Outer Sheath | CM. |

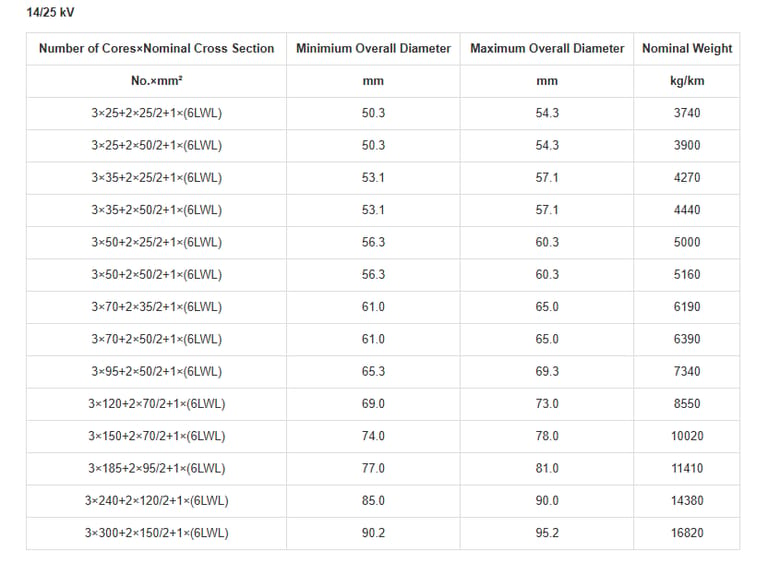

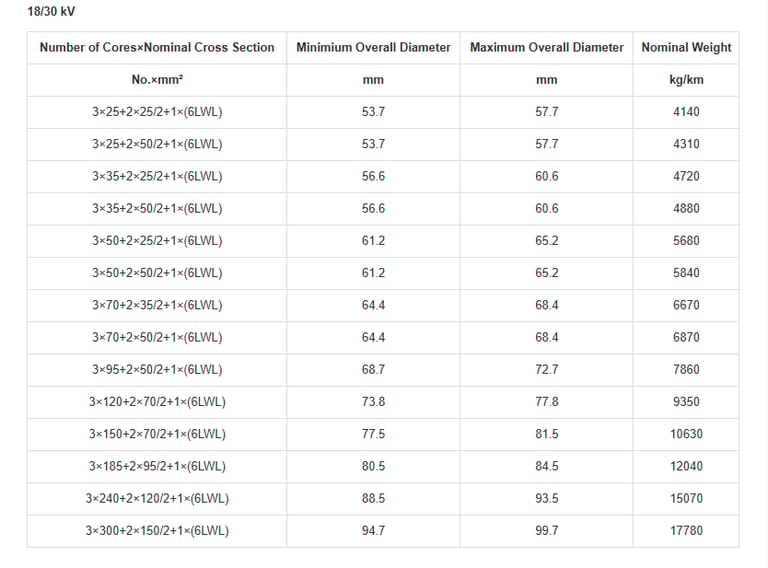

Dimensions and Weight

3.6/6 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+1×(6LWL) | 40.1 | 43.1 | 2650 |

3×25+2×50/2+1×(6LWL) | 42.4 | 45.4 | 3060 |

3×35+2×25/2+1×(6LWL) | 42.3 | 45.3 | 3060 |

3×35+2×50/2+1×(6LWL) | 44.0 | 47.0 | 3410 |

3×50+2×25/2+1×(6LWL) | 43.8 | 46.8 | 3490 |

3×50+2×50/2+1×(6LWL) | 46.1 | 49.1 | 3640 |

3×70+2×35/2+1×(6LWL) | 47.0 | 50.0 | 4350 |

3×70+2×50/2+1×(6LWL) | 52.0 | 56.0 | 5280 |

3×95+2×50/2+1×(6LWL) | 52.2 | 56.2 | 5550 |

3×120+2×70/2+1×(6LWL) | 49.6 | 50.9 | 7040 |

3×150+2×70/2+1×(6LWL) | 48.4 | 52.3 | 8000 |

3×185+2×95/2+1×(6LWL) | 51.3 | 55.3 | 9310 |

3×240+2×120/2+1×(6LWL) | 58.0 | 62.0 | 11940 |

3×300+2×150/2+1×(6LWL) | 63.2 | 67.2 | 14230 |

6/10 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+1×(6LWL) | 41.4 | 44.4 | 2770 |

3×25+2×50/2+1×(6LWL) | 43.1 | 46.1 | 3120 |

3×35+2×25/2+1×(6LWL) | 43.6 | 46.6 | 3190 |

3×35+2×50/2+1×(6LWL) | 44.7 | 47.7 | 3470 |

3×50+2×25/2+1×(6LWL) | 45.1 | 48.1 | 3620 |

3×50+2×50/2+1×(6LWL) | 46.8 | 49.8 | 4010 |

3×70+2×35/2+1×(6LWL) | 48.3 | 51.3 | 4500 |

3×70+2×50/2+1×(6LWL) | 52.7 | 56.7 | 5360 |

3×95+2×50/2+1×(6LWL) | 53.5 | 57.5 | 5710 |

3×120+2×70/2+1×(6LWL) | 57.2 | 61.2 | 6830 |

3×150+2×70/2+1×(6LWL) | 62.3 | 66.3 | 8180 |

3×185+2×95/2+1×(6LWL) | 65.3 | 69.3 | 9500 |

3×240+2×120/2+1×(6LWL) | 73.4 | 77.4 | 12160 |

3×300+2×150/2+1×(6LWL) | 78.6 | 82.6 | 14460 |

8.7/15 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+1×(6LWL) | 44.2 | 47.2 | 3050 |

3×25+2×50/2+1×(6LWL) | 45.4 | 48.4 | 3350 |

3×35+2×25/2+1×(6LWL) | 45.3 | 48.3 | 3320 |

3×35+2×50/2+1×(6LWL) | 47.0 | 50.0 | 3710 |

3×50+2×25/2+1×(6LWL) | 49.4 | 53.4 | 4160 |

3×50+2×50/2+1×(6LWL) | 51.2 | 55.2 | 4590 |

3×70+2×35/2+1×(6LWL) | 52.7 | 56.7 | 5080 |

3×70+2×50/2+1×(6LWL) | 55.0 | 59.0 | 5640 |

3×95+2×50/2+1×(6LWL) | 57.0 | 61.0 | 6160 |

3×120+2×70/2+1×(6LWL) | 62.1 | 66.1 | 7520 |

3×150+2×70/2+1×(6LWL) | 65.7 | 69.7 | 8670 |

3×185+2×95/2+1×(6LWL) | 68.7 | 72.7 | 10010 |

3×240+2×120/2+1×(6LWL) | 76.8 | 80.8 | 12730 |

3×300+2×150/2+1×(6LWL) | 82.0 | 86.0 | 15080 |

12/20 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+1×(6LWL) | 45.5 | 48.5 | 3140 |

3×25+2×50/2+1×(6LWL) | 47.2 | 50.2 | 3530 |

3×35+2×25/2+1×(6LWL) | 48.3 | 51.3 | 3640 |

3×35+2×50/2+1×(6LWL) | 51.0 | 55.0 | 4240 |

3×50+2×25/2+1×(6LWL) | 52.5 | 56.5 | 4530 |

3×50+2×50/2+1×(6LWL) | 52.5 | 56.5 | 4690 |

3×70+2×35/2+1×(6LWL) | 55.7 | 59.7 | 5460 |

3×70+2×50/2+1×(6LWL) | 58.0 | 62.0 | 6040 |

3×95+2×50/2+1×(6LWL) | 61.4 | 65.4 | 6770 |

3×120+2×70/2+1×(6LWL) | 65.1 | 69.1 | 7950 |

3×150+2×70/2+1×(6LWL) | 68.7 | 72.7 | 9130 |

3×185+2×95/2+1×(6LWL) | 73.2 | 77.2 | 10770 |

3×240+2×120/2+1×(6LWL) | 79.8 | 83.8 | 13260 |

3×300+2×150/2+1×(6LWL) | 86.3 | 91.3 | 16040 |

South Africa’s mining sector is among the most resource-rich and technologically demanding industries in the world. From deep-level gold and platinum mines to massive open-pit coal and iron ore operations, modern mining requires robust, reliable, and intelligent power distribution systems. One of the cable technologies that has recently gained prominence is the (N)TSCGEWOEU medium-voltage fixed installation cable with fiber optics.

Unlike traditional power cables, (N)TSCGEWOEU cables combine electrical power transmission with integrated fiber optic communication, enabling real-time data transfer, condition monitoring, and predictive maintenance. This innovation directly addresses current industry challenges in South Africa—such as load shedding, operational efficiency, and worker safety—while also aligning with global trends in digitalization and smart mining.

What Is (N)TSCGEWOEU Cable?

The (N)TSCGEWOEU cable is a medium-voltage power and control cable with integrated fiber optics, designed for fixed installation in demanding environments such as mining conveyors, material handling equipment, submersible pumps, and shiftable units.

It is built according to VDE 0250 Part 813 standards, which ensure high levels of safety, insulation performance, and resistance to mechanical stress. The unique feature of this cable is the fiber optic core, which allows simultaneous transmission of power and data—a critical advantage in modern automated and remote-controlled mining systems.

Key Benefits of (N)TSCGEWOEU Cables

Dual Functionality (Power + Data)

The integration of fiber optics allows not only power transmission but also real-time communication, enabling predictive maintenance and operational efficiency.High Mechanical Strength

The robust sheath materials (EPR and CM) withstand abrasion, oil, UV radiation, and harsh environmental conditions typical in South Africa’s mines.Flexibility for Harsh Installations

Designed for fixed installations along conveyors, cable booms, and pump systems, these cables can handle vibration, tension, and continuous movement.Enhanced Safety

The semiconductive layers and split earth conductor provide protection against faults, reducing fire risks and ensuring compliance with mining safety standards.Future-Ready for Smart Mining

As South Africa increasingly adopts digital mining systems with IoT sensors and AI-driven monitoring, the built-in fiber optics ensure seamless data integration

Applications in Mining and Heavy Industry

The versatility of (N)TSCGEWOEU cables makes them suitable for multiple sectors:

Mining: Powering and monitoring conveyors, pumps, and shiftable units in deep-level and surface mines.

Ports and Material Handling: Supplying energy to cranes, loading booms, and automated handling systems.

Submersible Pumps: Ensuring reliable operation in dewatering systems for flooded shafts or tunnels.

Heavy Industry: Steel plants, cement factories, and energy-intensive operations that require both power and monitoring.

Frequently Asked Questions (FAQ)

Q1. What does (N)TSCGEWOEU stand for?

It refers to a German VDE-standardized cable designation: N for standard cable, TSCGEWOEU for medium-voltage flexible installation cable with enhanced protective features and fiber optics.

Q2. Why include fiber optics in a power cable?

The fiber optics allow real-time communication, monitoring of cable health, and integration with digital mine control systems—critical for modern smart mining.

Q3. What voltage levels are available?

These cables are manufactured for 3.6/6 kV up to 18/30 kV, making them versatile for both low and medium-voltage mining operations.

Q4. Can they be used in South Africa’s underground mines?

Yes. They are well-suited for deep-level mining, conveyors, and submersible pump units, provided installations comply with SANS and VDE standards.

Q5. How long do these cables last?

With proper installation and maintenance, (N)TSCGEWOEU cables can last 15–25 years, depending on environmental conditions.

Q6. Are they resistant to water and oil?

Yes. The EPR and CM sheaths provide excellent resistance to oil, water, and chemicals, making them ideal for harsh environments.

Q7. How do they compare with standard mining cables?

Unlike conventional mining cables, they combine power transmission and fiber optic communication, reducing the need for separate communication lines.

The (N)TSCGEWOEU medium-voltage fixed installation cable with fiber optics represents a significant step forward in industrial cabling technology. Its dual functionality, high mechanical resilience, and adaptability to South Africa’s demanding mining and heavy industry environments make it a future-ready solution.

As the country continues to modernize its mining sector and adapt to the global push for digital transformation, cables like (N)TSCGEWOEU will play a central role in ensuring safer, smarter, and more efficient operations.

From powering conveyors deep underground to enabling real-time data flow for predictive maintenance, these cables exemplify the integration of traditional electrical engineering with modern communication technologies—a combination that is not only technically sound but also strategically essential for South Africa’s future industrial success.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430