Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGEWOEU Medium-Voltage Fixed Installation Cable Without Fibre Optics

Comprehensive Guide to (N)TSCGEWOEU Medium-Voltage Fixed Installation Cables for Mining and Heavy Industry Applications in South Africa

(N)TSCGEWOEU Medium-Voltage Fixed Installation Cable Without Fibre Optics

Applications | These cables are used for laying alongside the conveyor belts (also for shiftable units)and on material handling equipment (even with continuous movementsuch as in cable booms or as connection between upperand lower car) and for connection of submersible pump units. |

Standards | Based on VDE 0250 Part 813 |

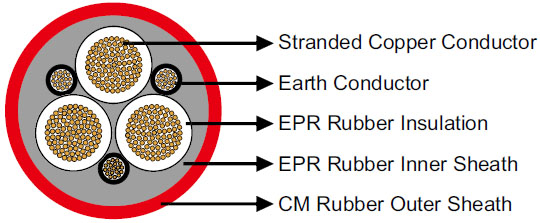

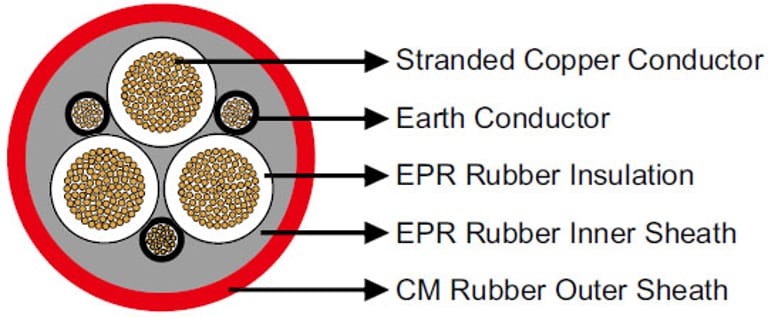

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Semiconductive layer. |

Insulation | EPR. |

Outer Conductor Layer | Semiconductive layer. |

Earth Conductor | Split into three in the outer interstices. |

InnerSheath | EPR. |

Outer Sheath | CM. |

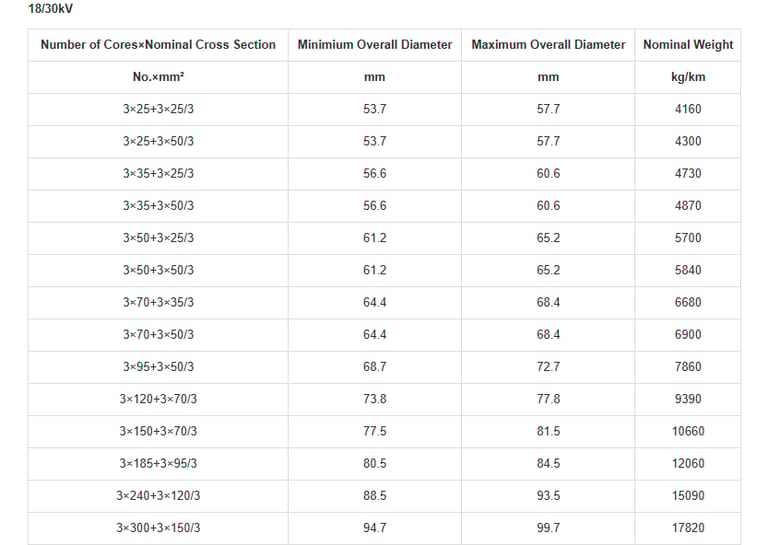

Dimensions and Weight

3.6/6 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 36.7 | 39.7 | 2320 |

3×25+3×50/3 | 40.6 | 43.6 | 2860 |

3×35+3×25/3 | 40.5 | 43.5 | 2860 |

3×35+3×50/3 | 42.3 | 45.3 | 3220 |

3×50+3×25/3 | 43.8 | 46.8 | 3500 |

3×50+3×50/3 | 43.8 | 46.8 | 3650 |

3×70+3×35/3 | 47.0 | 50.0 | 4360 |

3×70+3×50/3 | 49.7 | 53.7 | 5010 |

3×95+3×50/3 | 52.2 | 56.2 | 5550 |

3×120+3×70/3 | 55.9 | 59.9 | 6690 |

3×150+3×70/3 | 61.0 | 65.0 | 8030 |

3×185+3×95/3 | 64.0 | 68.0 | 9320 |

3×240+3×120/3 | 72.1 | 76.1 | 11960 |

3×300+3×150/3 | 77.3 | 81.3 | 14260 |

6/10 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 39.0 | 42.0 | 2520 |

3×25+3×50/3 | 41.4 | 44.4 | 2930 |

3×35+3×25/3 | 41.8 | 44.8 | 2980 |

3×35+3×50/3 | 43.6 | 46.6 | 3350 |

3×50+3×25/3 | 45.1 | 48.1 | 3640 |

3×50+3×50/3 | 45.1 | 48.1 | 3780 |

3×70+3×35/3 | 48.3 | 51.3 | 4500 |

3×70+3×50/3 | 48.3 | 51.3 | 4730 |

3×95+3×50/3 | 53.5 | 57.5 | 5710 |

3×120+3×70/3 | 57.2 | 61.2 | 6860 |

3×150+3×70/3 | 62.3 | 66.3 | 8210 |

3×185+3×95/3 | 65.3 | 69.3 | 9510 |

3×240+3×120/3 | 73.4 | 77.4 | 12170 |

3×300+3×150/3 | 78.6 | 82.6 | 14500 |

8.7/15 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 42.5 | 45.5 | 2850 |

3×25+3×50/3 | 44.2 | 47.2 | 3210 |

3×35+3×25/3 | 45.3 | 48.3 | 3340 |

3×35+3×50/3 | 45.3 | 48.3 | 3480 |

3×50+3×25/3 | 49.4 | 53.4 | 4180 |

3×50+3×50/3 | 49.4 | 53.4 | 4320 |

3×70+3×35/3 | 52.7 | 56.7 | 5090 |

3×70+3×50/3 | 52.7 | 56.7 | 5310 |

3×95+3×50/3 | 57.0 | 61.0 | 6160 |

3×120+3×70/3 | 62.1 | 66.1 | 7550 |

3×150+3×70/3 | 65.7 | 69.7 | 8710 |

3×185+3×95/3 | 68.7 | 72.7 | 10020 |

3×240+3×120/3 | 76.8 | 80.8 | 12750 |

3×300+3×150/3 | 82.0 | 86.0 | 15110 |

12/20 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 45.5 | 48.5 | 3150 |

3×25+3×50/3 | 45.5 | 48.5 | 3300 |

3×35+3×25/3 | 48.3 | 51.3 | 3660 |

3×35+3×50/3 | 48.3 | 51.3 | 3800 |

3×50+3×25/3 | 52.5 | 56.5 | 4540 |

3×50+3×50/3 | 52.5 | 56.5 | 4680 |

3×70+3×35/3 | 55.7 | 59.7 | 5460 |

3×70+3×50/3 | 55.7 | 59.7 | 5690 |

3×95+3×50/3 | 61.4 | 65.4 | 6770 |

3×120+3×70/3 | 65.1 | 69.1 | 7980 |

3×150+3×70/3 | 68.7 | 72.7 | 9170 |

3×185+3×95/3 | 73.2 | 77.2 | 10780 |

3×240+3×120/3 | 79.8 | 83.8 | 13280 |

3×300+3×150/3 | 86.3 | 91.3 | 16070 |

14/25 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 50.3 | 54.3 | 3750 |

3×25+3×50/3 | 50.3 | 54.3 | 3900 |

3×35+3×25/3 | 53.1 | 57.1 | 4290 |

3×35+3×50/3 | 53.1 | 57.1 | 4430 |

3×50+3×25/3 | 56.3 | 60.3 | 5020 |

3×50+3×50/3 | 56.3 | 60.3 | 5160 |

3×70+3×35/3 | 61.0 | 65.0 | 6190 |

3×70+3×50/3 | 61.0 | 65.0 | 6410 |

3×95+3×50/3 | 65.3 | 69.3 | 7340 |

3×120+3×70/3 | 69.0 | 73.0 | 8580 |

3×150+3×70/3 | 74.0 | 78.0 | 10050 |

3×185+3×95/3 | 77.0 | 81.0 | 11430 |

3×240+3×120/3 | 85.0 | 90.0 | 14400 |

3×300+3×150/3 | 90.2 | 95.2 | 16860 |

Mining and heavy industry operations in South Africa are among the most power-intensive sectors in the world. Whether it is powering conveyor systems, operating submersible pumps, or running continuous material handling equipment, reliable electricity supply through robust cabling systems is indispensable. One of the key cable types used in such demanding environments is the (N)TSCGEWOEU medium-voltage fixed installation cable.

Understanding (N)TSCGEWOEU Cables

(N)TSCGEWOEU is a designation for a specific type of medium-voltage power cable designed for fixed and flexible installations in mining and heavy industry.

Key Characteristics:

Designed for medium-voltage transmission (3.6/6 kV up to 18/30 kV).

Suitable for fixed laying alongside conveyor belts, shiftable units, and moving equipment such as cable booms.

Can be used as a connection for submersible pump units, even under mechanically demanding conditions.

Built for continuous movement, making it ideal for material handling systems.

Unlike standard industrial power cables, (N)TSCGEWOEU cables are constructed with high mechanical resilience, flexibility, and electrical stability, making them suitable for harsh mining environments.

Benefits of (N)TSCGEWOEU Cables

High Flexibility – Facilitates use in moving equipment such as cable booms and shiftable conveyors.

Thermal Resistance – EPR insulation withstands elevated operating temperatures.

Durability – Outer sheath resists oil, abrasion, ozone, and UV exposure.

Electrical Safety – Semiconductive layers reduce the risk of partial discharges and faults.

Versatility – Suitable for both fixed installation and continuous movement applications.

Compliance – Built according to VDE 0250 Part 813, recognized internationally for safety.

Usage Scenarios in South Africa

South Africa’s gold, platinum, and coal mines present some of the toughest conditions for power cables. (N)TSCGEWOEU cables are particularly suited to:

Underground Mines: Powering shuttle conveyors and crushers.

Open-Pit Mines: Running long conveyors exposed to sun, dust, and rain.

Submersible Pumps: Providing reliable power in dewatering operations, especially in deep-level gold mines.

Material Handling Plants: Supplying stacker-reclaimers and ship loaders in ports.

Case Example: Coal Mining in Mpumalanga

A coal mine in Mpumalanga reported frequent cable failures due to mechanical stress on conveyor power supplies. After replacing older cables with (N)TSCGEWOEU 8.7/15 kV cables, downtime was reduced by 40%, while maintenance costs dropped significantly.

Case Example: Platinum Mines in Rustenburg

A platinum mine introduced (N)TSCGEWOEU 12/20 kV cables for submersible pumps operating in highly acidic water. The EPR insulation’s chemical resistance ensured longer cable lifespans compared to traditional PVC cables.

Frequently Asked Questions (FAQ)

Q1. What is the main difference between (N)TSCGEWOEU and standard medium-voltage cables?

A1. (N)TSCGEWOEU is specially designed for flexibility and mechanical durability, making it suitable for moving installations in mining and heavy industries.

Q2. Can these cables be used underwater?

A2. Yes, they are commonly used in submersible pump applications, but only within the specified voltage and environmental limits.

Q3. Are these cables flame-retardant?

A3. Yes, the outer sheath material is flame-retardant and resistant to oil, ozone, and UV exposure.

Q4. Do they comply with South African standards?

A4. While based on VDE 0250 Part 813, they must also comply with NRCS approval for use in South Africa.

Q5. What is the expected service life?

A5. With proper installation and maintenance, service life can exceed 15 years, even in demanding environments.

The (N)TSCGEWOEU medium-voltage fixed installation cable represents a reliable, durable, and versatile solution for South Africa’s mining and heavy industry applications. Its advanced insulation system, mechanical resilience, and compliance with international standards make it indispensable in powering conveyors, pumps, and other heavy-duty equipment.

As South Africa’s mining sector faces challenges of energy efficiency, safety, and sustainability, adopting robust cabling solutions like (N)TSCGEWOEU will be critical for minimizing downtime, enhancing worker safety, and ensuring long-term operational success.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430