Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTSCGEWOEU Medium-Voltage Flexible Cable For Use In Water VDE 0250 Part 813

Comprehensive Guide to NTSCGEWOEU Medium-Voltage Flexible Cables: How They Revolutionize Water-Based Mining and Heavy Industry Applications in South Africa

NTSCGEWOEU Medium-Voltage Flexible Cable For Use In Water VDE 0250 Part 813

Applications | These cables are designed for operation inwater for connectionto dredgers, floating docks, pumps, etc., in applications where high mechanicalstresses are to be expected, also suitable for use in sewage, salt water and brackishwater at water depths of up to 500 m. |

Standards | VDE 0250 Part 813 |

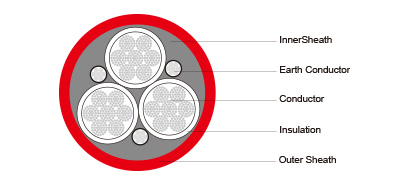

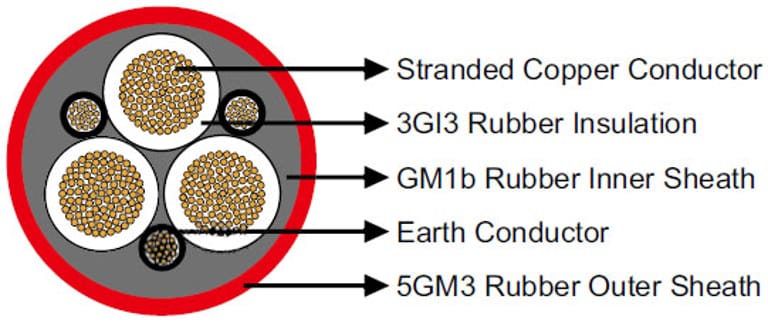

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Semiconductive layer. |

Insulation | Rubbertype 3GI3. |

Outer Conductor Layer | Semiconductive layer. |

Earth Conductor | Split into three in theouter interstices or Individual concentric distributed over core insulating coverings (coding…../3E) or incorporated as a fourth core. |

InnerSheath | Rubber compound type GM1b with characteristics of waterproof and preventionof formation of water bubbles. |

Outer Sheath | Waterproof rubber type 5GM3. |

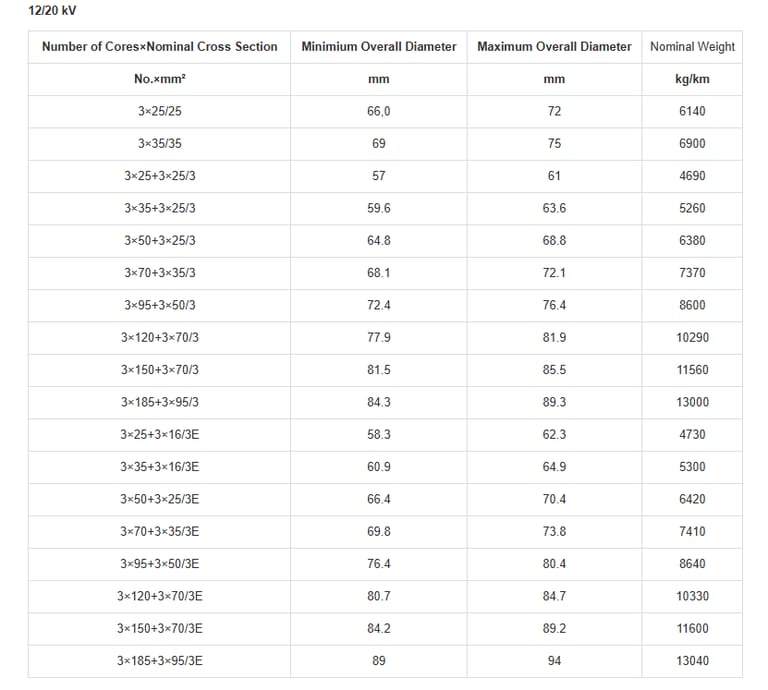

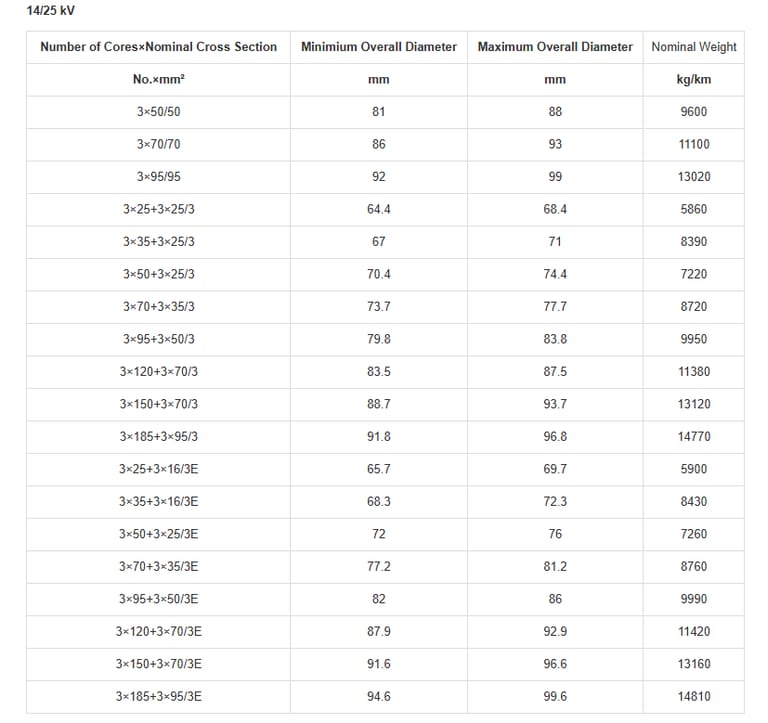

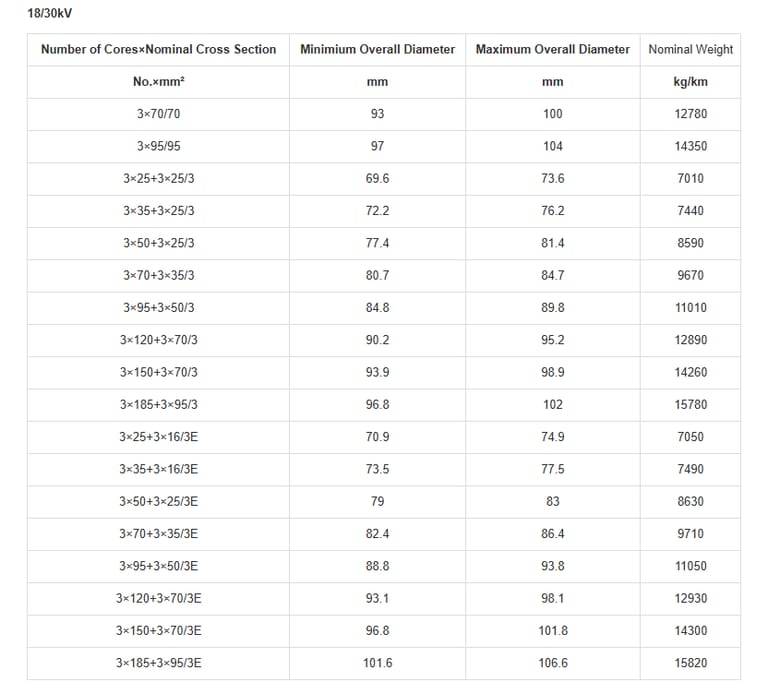

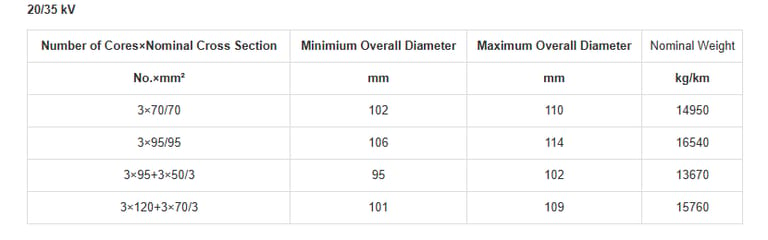

Dimensions and Weight

1.8/3kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 38.6 | 41.6 | 2480 |

3×35+3×25/3 | 42.5 | 45.5 | 3090 |

3×50+3×25/3 | 46 | 49 | 3750 |

3×70+3×35/3 | 49.2 | 52.2 | 4620 |

3×95+3×50/3 | 57.2 | 61.2 | 6200 |

3×120+3×70/3 | 60.9 | 64.9 | 7390 |

3×150+3×70/3 | 66.3 | 70.3 | 8830 |

3×185+3×95/3 | 69.4 | 73.4 | 10170 |

3×25+3×16/3E | 41.3 | 44.3 | 1180 |

3×35+3×16/3E | 43.9 | 46.9 | 1650 |

3×50+3×25/3E | 47.8 | 50.8 | 2310 |

3×70+3×35/3E | 52.5 | 56.5 | 3220 |

3×95+3×50/3E | 59.4 | 63.4 | 4335 |

3×120+3×70/3E | 65.5 | 69.5 | 5480 |

3×150+3×70/3E | 69.2 | 73.2 | 6800 |

3×185+3×95/3E | 72.2 | 76.2 | 8375 |

3.6/6kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×16/16 | 47 | 52 | 3240 |

3×25/25 | 50 | 55 | 3870 |

3×35/35 | 55 | 55 | 4780 |

3×50/50 | 59 | 64 | 5700 |

3×70/70 | 64 | 70 | 7000 |

3×25+3×25/3 | 44.7 | 47.7 | 3120 |

3×35+3×25/3 | 47.3 | 50.3 | 3600 |

3×50+3×25/3 | 52.2 | 56.2 | 4560 |

3×70+3×35/3 | 55.5 | 59.5 | 5470 |

3×95+3×50/3 | 59.8 | 63.8 | 6570 |

3×120+3×70/3 | 65.3 | 69.3 | 8090 |

3×150+3×70/3 | 68.9 | 72.9 | 9250 |

3×185+3×95/3 | 72 | 76 | 10600 |

3×25+3×16/3E | 46 | 49 | 3160 |

3×35+3×16/3E | 48.6 | 51.6 | 3640 |

3×50+3×25/3E | 54 | 58 | 4600 |

3×70+3×35/3E | 57.2 | 61.2 | 5510 |

3×95+3×50/3E | 63.8 | 67.8 | 6610 |

3×120+3×70/3E | 68.1 | 72.1 | 8130 |

3×150+3×70/3E | 71.8 | 75.8 | 9290 |

3×185+3×95/3E | 76.6 | 80.6 | 10840 |

6/10 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×16/16 | 49 | 54 | 3450 |

3×25/25 | 54 | 59 | 4350 |

3×35/35 | 57 | 62 | 5050 |

3×25+3×25/3 | 46.4 | 49.4 | 3320 |

3×35+3×25/3 | 49 | 52 | 3810 |

3×50+3×25/3 | 54 | 58 | 4780 |

3×70+3×35/3 | 57.2 | 61.2 | 5700 |

3×95+3×50/3 | 61.5 | 65.5 | 6830 |

3×120+3×70/3 | 67 | 71 | 8360 |

3×150+3×70/3 | 70.7 | 74.7 | 9530 |

3×185+3×95/3 | 73.7 | 77.7 | 10890 |

3×25+3×16/3E | 47.8 | 50.8 | 3360 |

3×35+3×16/3E | 51.9 | 55.9 | 3850 |

3×50+3×25/3E | 55.5 | 59.5 | 4820 |

3×70+3×35/3E | 59 | 63 | 5740 |

3×95+3×50/3E | 65.5 | 69.5 | 6870 |

3×120+3×70/3E | 69.8 | 73.8 | 8400 |

3×150+3×70/3E | 73.5 | 77.5 | 9570 |

3×185+3×95/3E | 78.3 | 82.3 | 10930 |

8.7/15 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 52.7 | 56.7 | 4050 |

3×35+3×25/3 | 55.3 | 59.3 | 4650 |

3×50+3×25/3 | 58.7 | 62.7 | 5390 |

3×70+3×35/3 | 63.8 | 67.8 | 6740 |

3×95+3×50/3 | 68.1 | 72.1 | 7870 |

3×120+3×70/3 | 71.7 | 75.7 | 9150 |

3×150+3×70/3 | 77.2 | 81.2 | 10770 |

3×185+3×95/3 | 80.2 | 84.2 | 12310 |

3×25+3×16/3E | 54 | 58 | 4090 |

3×35+3×16/3E | 56.6 | 60.6 | 4690 |

3×50+3×25/3E | 60.3 | 64.3 | 5430 |

3×70+3×35/3E | 65.5 | 69.5 | 6780 |

3×95+3×50/3E | 70.3 | 74.3 | 7910 |

3×120+3×70/3E | 76.4 | 80.4 | 9190 |

3×150+3×70/3E | 80.1 | 84.1 | 10810 |

3×185+3×95/3E | 83.1 | 87.1 | 12350 |

South Africa's mining and heavy industry sectors are undergoing a technological evolution, demanding advanced solutions for power transmission under extreme conditions. Among these innovations, NTSCGEWOEU medium-voltage flexible cables have emerged as a critical component for water-based and high-mechanical-stress applications. Whether for dredgers, floating docks, pumps, or submerged installations up to 500 meters underwater, these cables are engineered to deliver exceptional performance, reliability, and safety.

What Are NTSCGEWOEU Medium-Voltage Flexible Cables?

NTSCGEWOEU cables are medium-voltage flexible power cables designed according to VDE 0250 Part 813 standards. They are primarily engineered for use in water-based environments, such as rivers, dams, and coastal industrial facilities, and can withstand mechanical stresses in challenging conditions. These cables are suitable for sewage, saltwater, and brackish water applications at depths of up to 500 meters, making them particularly useful for South Africa’s mining and dredging industries.

Benefits of NTSCGEWOEU Cables

The adoption of NTSCGEWOEU cables provides numerous benefits for South African mining and industrial operations:

Waterproof and Submersible:

The cable can operate safely in fresh, brackish, and saltwater at depths up to 500 meters.Mechanical Resilience:

Designed to withstand high mechanical stress, the cable resists abrasion, bending, and dynamic loads often found in dredging and mining operations.Flexibility:

The stranded copper conductor allows easy installation in moving equipment like floating docks, dredgers, and mobile pumps.Electrical Safety:

Multi-layer insulation and semiconductive layers ensure minimal electrical losses and enhanced safety in wet environments.Longevity:

High-quality rubber sheaths prevent water ingress and chemical corrosion, increasing cable lifespan.

Future Trends and Applications

With South Africa’s mining industry investing in automation, dredging, and water-based operations, the demand for reliable, high-performance medium-voltage flexible cables is growing. NTSCGEWOEU cables are increasingly integrated into:

Automated dredging systems for mineral recovery,

Floating industrial platforms for offshore and river-based projects,

Hybrid mining operations combining water-based and dry processes,

Environmentally sensitive operations requiring minimal maintenance and durable equipment.

NTSCGEWOEU medium-voltage flexible cables represent a game-changing solution for South Africa’s water-based and high-stress industrial applications. With their robust mechanical design, water resistance, and electrical reliability, these cables have become indispensable for mining, dredging, and heavy industry operations. Proper installation, maintenance, and adherence to technical specifications can maximize cable lifespan, reduce downtime, and ensure operational safety.

For South African engineers, project managers, and industrial operators, investing in NTSCGEWOEU cables is not just a technical choice—it’s a strategic decision that enhances efficiency, safety, and long-term cost savings in challenging industrial environments.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430