Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGEWOEU Medium-Voltage Reeling Cable With Fiber Optics VDE 0250 Part 813

(N)TSCGEWOEU Medium-voltage Reeling Cables with Fiber Optics Revolutionizing South African Mining and Heavy Industry with Robust Connectivity, Durability, and Efficiency.

(N)TSCGEWOEU Medium-Voltage Reeling Cable With Fiber Optics VDE 0250 Part 813

Applications | These cables are used for connection of large mobile equipment such asexcavators and spreaders, gantrycranes, etc., under very highmechanical loads,suitablefor motorised reeling on monospiralor level-wind reelers. |

Standards | Based on VDE 0250 Part 813 |

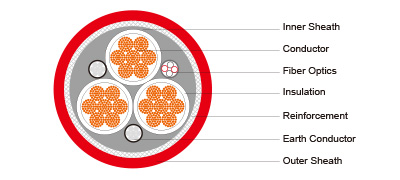

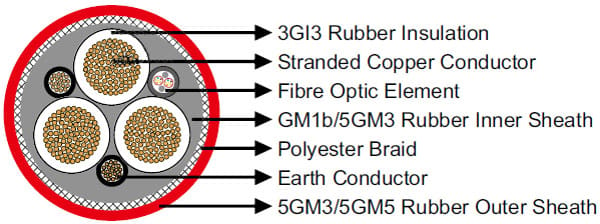

Construction  | |

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Semiconductive layer. |

Insulation | EPR type 3GI3. |

Outer Conductor Layer | Semiconductive layer. |

Earth Conductor | Split into two in the outer interstices. |

InnerSheath | Rubber type GM1b/5GM3. |

Reinforcement | Polyester anti-torsion braid. |

Outer Sheath | Rubber type 5GM3/5GM5, flame retardant and oil resistant. |

Dimensions and Weight

3.6/6 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+12×LWL | 39 | 42 | 2410 |

3×35+2×25/2+12×LWL | 42 | 45 | 2995 |

3×50+2×25/2+12×LWL | 45 | 48 | 3645 |

3×70+2×35/2+12×LWL | 50 | 54 | 4760 |

3×95+2×50/2+12×LWL | 54 | 58 | 5580 |

3×120+2×70/2+12×LWL | 58 | 62 | 6690 |

3×150+2×70/2+12×LWL | 63 | 67 | 7990 |

3×185+2×95/2+12×LWL | 67 | 72 | 9330 |

6/10 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+12×LWL | 40 | 43 | 2450 |

3×35+2×25/2+12×LWL | 43 | 46 | 3035 |

3×50+2×25/2+12×LWL | 46 | 49 | 3690 |

3×70+2×35/2+12×LWL | 51 | 55 | 4800 |

3×95+2×50/2+12×LWL | 55 | 59 | 5620 |

3×120+2×70/2+12×LWL | 59 | 63 | 6740 |

3×150+2×70/2+12×LWL | 64 | 68 | 8040 |

3×185+2×95/2+12×LWL | 68 | 72 | 9380 |

12/20 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+12×LWL | 46 | 49 | 3050 |

3×35+2×25/2+12×LWL | 49 | 52 | 3490 |

3×50+2×25/2+12×LWL | 53 | 57 | 4340 |

3×70+2×35/2+12×LWL | 57 | 61 | 5320 |

3×95+2×50/2+12×LWL | 61 | 65 | 6360 |

3×120+2×70/2+12×LWL | 67 | 71 | 7810 |

3×150+2×70/2+12×LWL | 70 | 74 | 8900 |

3×185+2×95/2+12×LWL | 76 | 80 | 10700 |

18/30 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+2×25/2+12×LWL | 55 | 59 | 3960 |

3×35+2×25/2+12×LWL | 58 | 62 | 4550 |

3×50+2×25/2+12×LWL | 63 | 67 | 5510 |

3×70+2×35/2+12×LWL | 66 | 70 | 6560 |

3×95+2×50/2+12×LWL | 71 | 75 | 7850 |

3×120+2×70/2+12×LWL | 76 | 80 | 10690 |

3×185+2×95/2+12×LWL | 86 | 90 | 12550 |

In the heart of South Africa’s mining and heavy industry sectors, where rugged environments and relentless mechanical demands dominate, the need for reliable, high-performance cabling solutions is paramount. The (N)TSCGEWOEU medium-voltage reeling cable with integrated fiber optics, designed to VDE 0250 Part 813 standards, stands out as a technological marvel. These cables power massive mobile equipment like excavators, spreaders, and gantry cranes while ensuring seamless data transmission through embedded fiber optics. This article delves into the intricacies of these cables, exploring their types, technical specifications, benefits, installation and maintenance recommendations, usage scenarios, and real-world applications in South Africa’s industrial landscape. We’ll also address frequently asked questions to provide a comprehensive understanding of this critical technology.

Understanding Medium-Voltage Reeling Cables with Fiber Optics

What Are Medium-Voltage Reeling Cables?

Medium-voltage reeling cables, such as the (N)TSCGEWOEU, are engineered for high-voltage applications (3.6/6 kV to 18/30 kV) under extreme mechanical stress. These cables are flexible, durable, and designed for motorized reeling systems, such as monospiral or level-wind reelers, commonly used in mining and heavy industry. The integration of fiber optics enables simultaneous power delivery and high-speed data transmission, making them ideal for modern industrial operations requiring real-time monitoring and control.

Benefits of (N)TSCGEWOEU Cables

Durability: The robust construction, including a polyester anti-torsion braid and flame-retardant, oil-resistant outer sheath, ensures longevity in harsh conditions like South African mines.

Flexibility: Class 5 copper conductors and EPR insulation allow the cables to endure continuous reeling and bending without degradation.

Integrated Data Transmission: Fiber optics enable real-time data transfer for monitoring equipment performance, enhancing operational efficiency.

Safety: Semiconductive layers and split earth conductors reduce electrical risks, critical in high-voltage applications.

Versatility: Available in multiple voltage ratings and core sizes, these cables suit diverse applications, from small cranes to massive excavators.

Installation and Maintenance Recommendations

Installation

Reeling System Compatibility: Ensure the cable is compatible with monospiral or level-wind reelers. Verify the reel’s tension and speed settings to prevent overstretching.

Bending Radius: Adhere to the minimum bending radius (typically 6–8 times the cable diameter) to avoid insulation damage.

Environmental Considerations: Install in environments free from excessive heat or chemical exposure beyond the cable’s resistance capabilities.

Professional Handling: Use trained technicians to install cables, ensuring proper grounding and connection to equipment.

Maintenance

Regular Inspections: Check for abrasions, cuts, or sheath damage monthly, especially in high-stress reeling applications.

Cleaning: Remove dust and debris from the cable surface to prevent degradation of the outer sheath.

Tension Monitoring: Regularly calibrate reeling systems to maintain optimal tension, reducing wear.

Fiber Optic Testing: Periodically test fiber optic performance to ensure data transmission integrity.

Usage Scenarios in South African Mining and Heavy Industry

South Africa’s mining sector, a cornerstone of the economy, relies heavily on robust infrastructure. The (N)TSCGEWOEU cables are ideal for:

Deep-Level Mining: In gold and platinum mines, these cables power large excavators and conveyors while transmitting data for remote monitoring, improving safety and efficiency.

Open-Pit Operations: In coal and diamond mines, the cables support spreaders and draglines, with fiber optics enabling real-time equipment diagnostics.

Port and Logistics: Gantry cranes at ports like Durban use these cables for reliable power and data connectivity, handling heavy cargo loads.

Case Study: Enhancing Efficiency in a South African Platinum Mine

In 2024, a major platinum mine in Rustenburg faced challenges with frequent cable failures due to the abrasive environment and high mechanical stress. By upgrading to (N)TSCGEWOEU 12/20 kV cables (3×95+2×50/2+12×LWL), the mine achieved:

Reduced Downtime: The cables’ durability minimized replacement frequency by 60%.

Improved Monitoring: Fiber optics enabled real-time equipment performance tracking, reducing maintenance costs by 25%.

Enhanced Safety: Flame-retardant sheaths and robust grounding reduced electrical hazards, aligning with South Africa’s stringent mining safety regulations.

This case underscores the cables’ role in addressing current industry trends, such as the push for automation and real-time data in South African mining.

Frequently Asked Questions (FAQ)

Q1: What makes (N)TSCGEWOEU cables suitable for mining?

A: Their robust construction, including flame-retardant, oil-resistant sheaths and anti-torsion braids, ensures durability under high mechanical loads. Integrated fiber optics support real-time data transmission, critical for modern mining operations.

Q2: Can these cables be used in other industries?

A: Yes, they are versatile for heavy industries like ports, construction, and manufacturing, where mobile equipment and data connectivity are essential.

Q3: How often should the cables be replaced?

A: Replacement depends on usage and maintenance. With proper care, they can last 5–10 years in high-stress environments.

Q4: Are the fiber optics prone to damage during reeling?

A: The fiber optics are protected within the cable’s reinforced structure, ensuring resilience against mechanical stress.

Q5: How do I choose the right voltage rating?

A: Select based on equipment power requirements and operational voltage. Consult with a cable supplier to match specifications like 3.6/6 kV or 18/30 kV to your needs.

The (N)TSCGEWOEU medium-voltage reeling cables with fiber optics are a game-changer for South Africa’s mining and heavy industry sectors. Their robust construction, flexibility, and integrated data capabilities address the unique challenges of these environments, from deep-level mines to bustling ports. By understanding their technical specifications, benefits, and maintenance needs, industries can optimize performance, safety, and efficiency. As South Africa continues to embrace automation and real-time monitoring, these cables will play a pivotal role in driving progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430