Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGEWOEU Medium-Voltage Reeling Cable Without Fibre Optics

(N)TSCGEWOEU Medium-Voltage Reeling Cable: Engineered for High Mechanical Loads, Flame Resistance, and Oil Resistance

(N)TSCGEWOEU Medium-Voltage Reeling Cable Without Fibre Optics

Applications | These cables are used for connection of large mobile equipment such asexcavators and spreaders, loading bridges, gantrycranes, construction machines, etc., under very highmechanical loads, in dry or damp environment, also inenvironments with high explosion risk. |

Standards | Based on VDE 0250 Part 813 |

Construction  | |

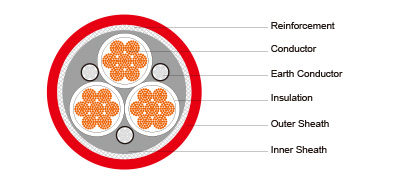

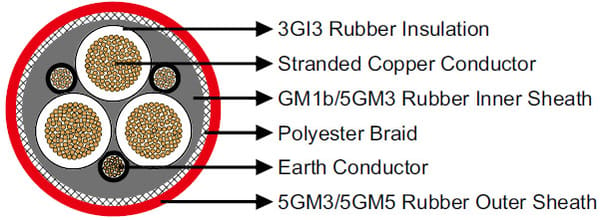

Conductors | Flexible strandedcopper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Semiconductive layer. |

Insulation | EPR type 3GI3. |

Outer Conductor Layer | Semiconductive layer. |

Earth Conductor | Incorporatedas a fourth core or distributed within the outer interstices. |

InnerSheath | Rubber type GM1b/5GM3. |

Reinforcement | Polyester anti-torsion braid. |

Outer Sheath | Chlorinatedrubber type 5GM3/5GM5, flame retardant and oil resistant. |

Dimensions and Weight

3.6/6kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 39 | 42 | 2410 |

3×35+3×25/3 | 42 | 45 | 2995 |

3×50+3×25/3 | 45 | 48 | 3645 |

3×70+3×35/3 | 50 | 54 | 4760 |

3×95+3×50/3 | 54 | 58 | 5580 |

3×120+3×70/3 | 58 | 62 | 6690 |

3×150+3×70/3 | 63 | 67 | 7990 |

3×185+3×95/3 | 67 | 72 | 9330 |

6/10 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 40 | 43 | 2450 |

3×35+3×25/3 | 43 | 46 | 3035 |

3×50+3×25/3 | 46 | 49 | 3690 |

3×70+3×35/3 | 51 | 55 | 4800 |

3×95+3×50/3 | 55 | 59 | 5620 |

3×120+3×70/3 | 59 | 63 | 6740 |

3×150+3×70/3 | 64 | 68 | 8040 |

3×185+3×95/3 | 69 | 74 | 9380 |

8.7/15 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 42.1 | 45.1 | 2707 |

3×25+3×50/3 | 43.8 | 46.8 | 3062 |

3×35+3×25/3 | 44.9 | 47.9 | 3198 |

3×35+3×50/3 | 44.9 | 47.9 | 3382 |

3×50+3×25/3 | 49.5 | 53.5 | 4083 |

3×50+3×50/3 | 49.5 | 53.5 | 4267 |

3×70+3×35/3 | 53.1 | 57.1 | 5028 |

3×70+3×50/3 | 53.1 | 57.1 | 5303 |

3×95+3×50/3 | 57.3 | 61.3 | 6216 |

3×120+3×70/3 | 63 | 67 | 7673 |

3×150+3×70/3 | 66.6 | 70.6 | 8852 |

3×185+3×95/3 | 70.5 | 74.5 | 10351 |

3×240+3×120/3 | 78 | 82 | 13125 |

3×300+3×150/3 | 84.9 | 89.9 | 16020 |

12/20 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 46 | 49 | 3050 |

3×35+3×25/3 | 49 | 52 | 3490 |

3×50+3×25/3 | 53 | 57 | 4340 |

3×70+3×35/3 | 57 | 61 | 5320 |

3×95+3×50/3 | 61 | 65 | 6360 |

3×120+3×70/3 | 67 | 71 | 7810 |

3×150+3×70/3 | 70 | 74 | 8900 |

3×185+3×95/3 | 76 | 80 | 10700 |

14/25 kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 49.9 | 53.9 | 3542 |

3×25+3×50/3 | 49.9 | 53.9 | 3726 |

3×35+3×25/3 | 52.7 | 56.7 | 4075 |

3×35+3×50/3 | 52.7 | 56.7 | 4258 |

3×50+3×25/3 | 56.4 | 60.4 | 4872 |

3×50+3×50/3 | 56.4 | 60.4 | 5054 |

3×70+3×35/3 | 61.5 | 65.5 | 6083 |

3×70+3×50/3 | 61.5 | 65.5 | 6356 |

3×95+3×50/3 | 65.8 | 69.8 | 7303 |

3×120+3×70/3 | 69.9 | 73.9 | 8652 |

3×150+3×70/3 | 75 | 79 | 10139 |

3×185+3×95/3 | 78.9 | 82.9 | 11705 |

3×240+3×120/3 | 86.2 | 91.2 | 14670 |

3×300+3×150/3 | 91.8 | 96.8 | 17332 |

18/30kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×25+3×25/3 | 55 | 59 | 3960 |

3×35+3×25/3 | 58 | 62 | 4550 |

3×50+3×25/3 | 63 | 67 | 5510 |

3×70+3×35/3 | 66 | 70 | 6560 |

3×95+3×50/3 | 71 | 75 | 7850 |

3×120+3×70/3 | 76 | 80 | 9410 |

3×150+3×70/3 | 80 | 84 | 10690 |

3×185+3×95/3 | 86 | 90 | 12550 |

What Are Medium-Voltage Reeling Cables?

Medium-voltage reeling cables are robust, flexible power cables designed for dynamic applications where equipment moves frequently, such as in mining operations or heavy industrial settings. The (N)TSCGEWOEU cable, compliant with VDE 0250 Part 813 standards, is specifically engineered for high mechanical loads, flame resistance, and oil resistance, making it ideal for harsh environments, including those with explosion risks.

Benefits of (N)TSCGEWOEU Cables

Durability Under Stress: The anti-torsion braid and robust sheathing withstand high mechanical loads, reducing wear and tear.

Safety in Hazardous Environments: Flame-retardant and oil-resistant properties make them suitable for explosion-prone areas like mines.

Flexibility: Class 5 copper conductors allow for repeated reeling and unreeling without compromising performance.

Versatility: Suitable for dry, damp, or high-risk environments, supporting diverse applications.

Longevity: High-quality materials like EPR insulation and chlorinated rubber sheathing extend service life, reducing replacement costs.

Installation and Maintenance Recommendations

Proper installation and maintenance are crucial for maximizing the performance and lifespan of medium-voltage reeling cables.

Installation Guidelines

Reeling Equipment: Use cable reels designed for medium-voltage cables to prevent over-bending or twisting. Ensure the reel’s bending radius complies with the cable’s minimum bending radius (typically 6–10 times the cable diameter).

Tension Control: Maintain proper tension during reeling to avoid overstretching or slack, which can damage the cable.

Environmental Considerations: In South African mines, protect cables from abrasive surfaces and extreme temperatures. Use cable guides to minimize friction.

Grounding: Ensure proper connection of the earth conductor to prevent electrical hazards.

Maintenance Tips

Regular Inspections: Check for abrasions, cuts, or sheath damage, especially in high-wear areas like cable entry points.

Cleaning: Remove dirt, oil, or chemicals from the sheath to maintain flame and oil resistance.

Tension Monitoring: Periodically verify reeling equipment tension settings to prevent stress on the cable.

Storage: Store unused cables in a dry, cool environment, coiled loosely to avoid kinking.

Usage Scenarios in South Africa

South Africa’s mining and heavy industry sectors, particularly in regions like Mpumalanga and the Northern Cape, rely heavily on medium-voltage reeling cables. These cables power critical equipment in gold, platinum, and coal mines, as well as in heavy industrial applications like steel production and port operations.

Case Study 1: Platinum Mining in Rustenburg

In a prominent platinum mine in Rustenburg, (N)TSCGEWOEU 8.7/15 kV cables (3×95+3×50/3) are used to power large excavators. The mine’s challenging environment, with high dust levels and explosion risks, demands cables that are both durable and safe. The flame-retardant and oil-resistant properties of these cables have reduced downtime by 20% compared to previous solutions, saving the mine significant operational costs. Regular maintenance, including monthly inspections and tension adjustments, ensures consistent performance.

Case Study 2: Coal Mining in Mpumalanga

A coal mine in Mpumalanga adopted (N)TSCGEWOEU 6/10 kV cables (3×50+3×25/3) for its spreaders. The cables’ flexibility and robust construction have enabled continuous operation in damp, abrasive conditions. By implementing a proactive maintenance schedule, the mine reduced cable replacement frequency by 30%, aligning with South Africa’s push for sustainable mining practices amid rising operational costs in 2025.

Frequently Asked Questions (FAQ)

1. What makes (N)TSCGEWOEU cables suitable for mining?

These cables are designed for high mechanical stress, with flame-retardant and oil-resistant properties, making them ideal for harsh, explosion-prone mining environments.

2. How often should these cables be inspected?

Monthly inspections are recommended, focusing on sheath integrity, abrasions, and tension settings. More frequent checks may be needed in high-wear scenarios.

3. Can these cables be used in wet environments?

Yes, the chlorinated rubber sheath and EPR insulation ensure reliable performance in damp conditions, common in underground mines.

4. What is the lifespan of a medium-voltage reeling cable?

With proper installation and maintenance, these cables can last 5–10 years, depending on usage intensity and environmental factors.

5. Are these cables compatible with automated mining equipment?

Absolutely. Their flexibility and high voltage ratings make them ideal for powering automated excavators and other modern equipment.

6. How do I choose the right cable size?

Select based on voltage requirements, equipment power demands, and reeling distance. Consult the manufacturer’s specifications (e.g., 3×185+3×95/3 for heavy-duty applications).

Medium-voltage reeling cables like the (N)TSCGEWOEU are the backbone of South Africa’s mining and heavy industry sectors, offering unmatched durability, safety, and flexibility. Their ability to withstand extreme conditions while powering critical equipment makes them essential for operational efficiency. By following proper installation and maintenance practices, industries can maximize cable lifespan and performance, contributing to cost savings and sustainability. As South Africa’s mining sector evolves with automation and electrification trends, these cables will continue to play a pivotal role in powering progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430