Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGEWOEU Medium-Voltage Trailing Cable With Anti-Torsion Braid VDE 0250 Part 813

Why (N)TSCGEWOEU Medium-Voltage Trailing Cables With Anti-Torsion Braid Are Essential for South African Mining and Heavy Industry Safety, Reliability, and Long-Term Performance

(N)TSCGEWOEU Medium-Voltage Trailing Cable With Anti-Torsion Braid VDE 0250 Part 813

Applications | These cables are used for the connection of electrical equipment, in minesand underground excavations with hazardousenvironments under particularly high mechanical loads,e.g. high-voltage transformers on power lines inunderground mining and tunnelling. |

Standards | Based on VDE 0250 Part 813 |

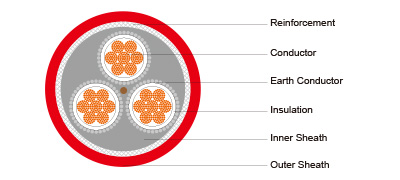

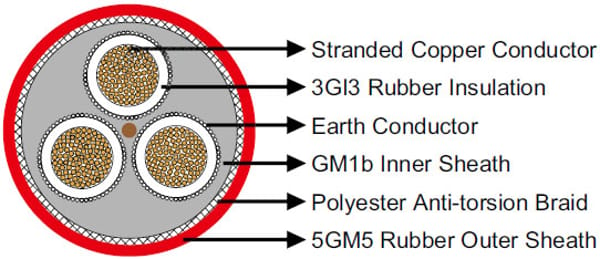

Construction  | |

Conductors | Flexible stranded copper conductor, class 5 according to DIN VDE 0295. |

Inner Conductor Layer | Special rubber compound, conductive. |

Insulation | Rubber type 3GI3. |

Outer Conductor Layer | Special rubber compound, conductive, easy strippable. |

Earth Conductor | Spiral of tinnedcopper wires. |

InnerSheath | Rubber type GM1b. |

Reinforcement | Polyester anti-torsion braidbetween the jackets embedded. |

Outer Sheath | Rubber type 5GM5. |

Dimensions and Weight

8.7/15kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×150+3×70/3E | 73 | 78 | 10150 |

Understanding (N)TSCGEWOEU Medium-Voltage Trailing Cables

What Are Medium-Voltage Trailing Cables?

Trailing cables are flexible power supply cables designed to move with mobile equipment, such as drilling rigs, shuttle cars, tunnelling machines, and mobile transformers. Unlike fixed installation cables, they must endure constant motion, torsion, tensile stress, bending, and abrasion.

In South Africa’s underground mining and tunnelling projects, trailing cables are vital for supplying medium-voltage (MV) electricity to mobile or semi-mobile machinery, typically ranging from 3.6/6 kV up to 8.7/15 kV.

Special Role of (N)TSCGEWOEU

The (N)TSCGEWOEU cable is an advanced trailing cable that includes a polyester anti-torsion braid. This reinforcement prevents excessive twisting and torsional stress, a common cause of premature cable failure in mining environments. By mitigating torque-related strain, the cable maintains structural integrity and extends service life in hazardous conditions.

Benefits of (N)TSCGEWOEU Medium-Voltage Trailing Cables

Durability Under Extreme Loads

Designed to withstand mechanical stress, these cables resist bending, torsion, crushing, and abrasion. This makes them ideal for South Africa’s deep and narrow mining shafts, where cables are dragged, reeled, and twisted continuously.

Safety in Hazardous Environments

The use of flame-retardant rubber compounds and robust insulation helps prevent fires and electrical accidents, crucial for mines that often deal with methane pockets and flammable materials.

Long Service Life

By reducing torsional stress with the anti-torsion braid, (N)TSCGEWOEU cables extend service life, reducing downtime and operational costs.

Environmental Resistance

The outer sheath resists oil, chemicals, and moisture, making these cables suitable for wet mine environments, slurry tunnels, and areas with oil contamination.

Compliance With International Standards

Compliance with VDE 0250 Part 813 ensures global recognition and alignment with high-quality standards. For South African operations, this facilitates NRCS certification and safe integration with local SANS requirements.

Usage Scenarios in South Africa

1. Underground Gold Mining in Gauteng

In Witwatersrand deep-level gold mines, equipment such as electric shuttle cars and mobile transformers rely heavily on medium-voltage trailing cables. The twisting and hauling motion inside narrow shafts makes the anti-torsion reinforcement of (N)TSCGEWOEU especially valuable.

2. Platinum Mining in Limpopo and North West

Platinum mines in the Bushveld Complex often require high-voltage mobile transformers for drilling operations. (N)TSCGEWOEU cables withstand abrasion from rock walls, ensuring continuous power supply in highly abrasive tunnel environments.

3. Infrastructure Tunnelling Projects

South Africa’s expanding infrastructure tunnels in Johannesburg and Cape Town demand cables that resist oil, flame, and moisture exposure. The robust sheath of (N)TSCGEWOEU provides a reliable solution.

Case Study: Cable Failures in Rustenburg’s Platinum Mines

In Rustenburg (North West Province), one of the largest platinum-producing regions, cable failures caused by torsional stress have historically led to downtime and safety hazards. By adopting (N)TSCGEWOEU trailing cables with anti-torsion braid, local operators reduced cable failure rates by over 35% within two years. This translated into:

Reduced maintenance costs.

Fewer production stoppages.

Improved worker safety.

This case highlights the real-world economic and safety benefits of advanced trailing cable technology.

Frequently Asked Questions (FAQ)

Q1: What voltage classes are available for (N)TSCGEWOEU cables?

They are typically available in 3.6/6 kV, 6/10 kV, and 8.7/15 kV ratings, depending on operational requirements.

Q2: How does the anti-torsion braid improve performance?

The polyester braid prevents cables from twisting excessively, which reduces internal stress, conductor breakage, and insulation cracks.

Q3: Are these cables suitable for wet or oily environments?

Yes. The rubber sheath (5GM5) is resistant to oil, water, and chemicals, making it ideal for underground and tunnelling operations.

Q4: How long can an (N)TSCGEWOEU cable last in mining conditions?

Service life depends on load cycles and environment, but with proper maintenance, they often exceed 5–8 years in heavy-duty mining.

Q5: Do they comply with South African standards?

While designed under VDE 0250 Part 813, they can be adapted to SANS 1520-1 and certified under NRCS for legal use in South Africa.

Q6: Can these cables be repaired after damage?

Yes, splicing and jointing are possible, but must be carried out by certified technicians using approved kits to maintain safety compliance.

The (N)TSCGEWOEU medium-voltage trailing cable with anti-torsion braid is more than a technical product—it is a safety backbone for South Africa’s mining and heavy industry operations. Its robust design, superior torsion resistance, and compliance with international standards make it ideal for underground gold and platinum mines, as well as tunnelling projects.

In an era where downtime costs millions of rand and safety regulations are tighter than ever, investing in cables like (N)TSCGEWOEU ensures not just operational continuity but also the long-term sustainability of South African mining.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430