Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGEWÖU - 3.6/6kV and 6/10kV Submersible Cable

The Robust (N)TSCGEWÖU 3.6/6kV and 6/10kV Submersible Cables for Harsh Marine and Mining Environments

(N)TSCGEWÖU-3.6/6kV and 6/10kV Submersible Cable

Application | Flexible supply cable for permanent salty and brackish water immersion up to 300 meters under high mechanical stresses. Suitable for pumps, dredges, floating docks, and trailing operations of opencast mining equipment. Applicable for indoor and outdoor use. |

Voltage Rating Uo/U | 3.6/6kV, 6/10kV |

Test Voltage | 3.6/6kV: 11kV |

Ambient Temperature | Fixed: -40°C to +80°C |

Minimum Bending Radius | Fixed: 6 x overall diameter |

Construction | |

Phase Conductor | Class 5 tinned copper conductor |

Insulation | Rubber compound |

Semi-Conductive Layers | Semi-conductive tape over the conductor and inner/outer semi-conductive rubber layer on the insulation |

Earth Conductor | Class 5 tinned copper conductor |

Central Filler | Semi-conductive compound on a textile polyester support |

Inner Sheath | EPR rubber compound waterproofing |

Outer Sheath | CM rubber compound waterproofing |

Sheath Colour | Black |

Standards | VDE 0250 Part 813, HD 22.16, VDE 0295, EN 60228 |

Why Choose NTSCGEWÖU Submersible Cables?

The true value of these 3.6/6kV and 6/10kV submersible cables emerges in their resilience. First, unparalleled water-proofing: the EPR inner and CM outer sheaths form a hydrostatic seal, preventing moisture ingress that plagues lesser cables in immersion up to 300m. Tinned copper conductors fend off corrosion, extending service life by decades in brackish or saline waters.

Mechanically, Class 5 stranding allows flexing under high stresses—think trailing behind dredges at speeds up to 1 m/s—without fatigue failure. Flame retardancy per IEC/EN 60332-1-2 minimizes fire risks in oily mining environments, while the black sheath resists UV degradation for outdoor longevity.

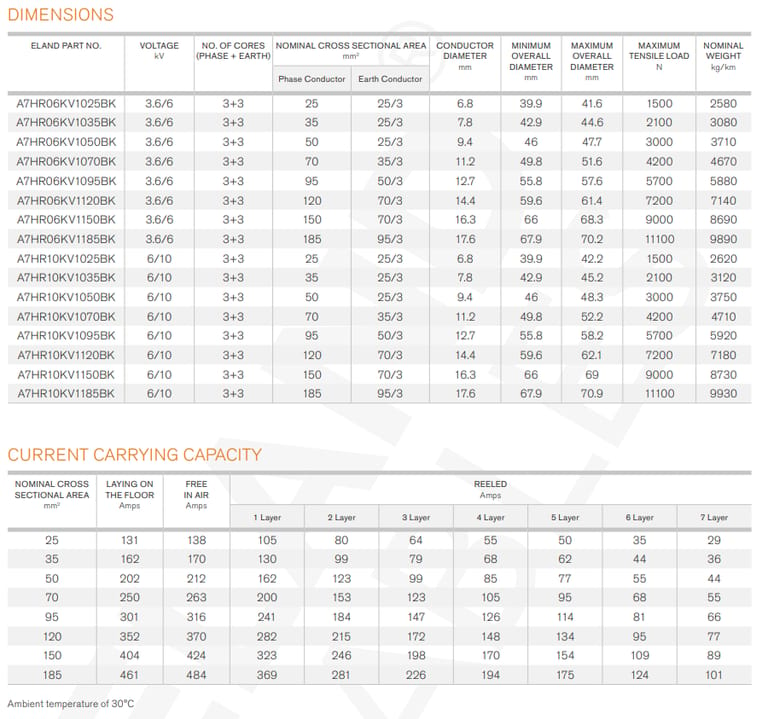

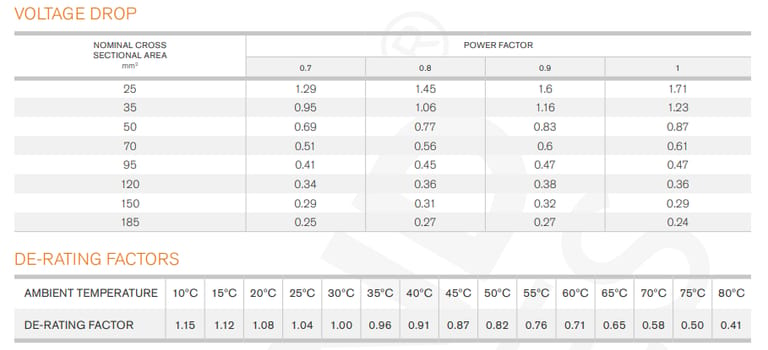

Electrically, semi-conductive layers ensure smooth voltage gradients, reducing dielectric losses and enhancing partial discharge resistance. This translates to lower operational costs: minimal voltage drop means fewer transformers, and high ampacity supports heavy loads like 484A free-air for 185 mm² at 6/10kV.

Environmentally, these cables align with sustainable practices. Their durability cuts replacement frequency, reducing waste, and oil-resistant properties suit eco-sensitive marine zones. In essence, NTSCGEWÖU cables aren't just conductors—they're investments in reliability, slashing downtime in critical ops by up to 40% compared to standard XLPE types.

Usage Scenarios:

Versatility defines the NTSCGEWÖU submersible cable's role. In marine settings, it's the go-to for permanent immersion: powering submersible pumps in offshore oil rigs or aquaculture farms, where it withstands tidal surges and biofouling. For floating docks, its trailing capability feeds electricity to cranes and lighting without snags, even in 80°C tropical heat.

In mining, opencast equipment like excavators and conveyors rely on its flexed installation for mobile power. Indoor/outdoor flexibility suits pump stations or dredges in riverine gold extractions, where brackish water immersion meets mechanical abrasion.

Emerging uses include renewable energy: underwater tidal turbines or wave energy converters demand this cable's 300m depth rating and -40°C cold tolerance for Arctic deployments. In urban flood control, submersible barriers use them for resilient grid ties, proving their adaptability across sectors.

The (N)TSCGEWÖU 3.6/6kV and 6/10kV submersible cables represent a pinnacle of cable technology—blending flexibility, waterproofing, and electrical prowess to power humanity's boldest ventures. From South African mines to global oceans, they deliver uninterrupted energy where others falter, fostering innovation in mining, marine ops, and beyond. As we push boundaries, these unassuming lifelines remind us: true strength lies in the details. For specs or sourcing, consult standards like VDE 0250—your next project might just depend on it.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430