Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSCGEWÖU - 8.7/15kV and 12/20kV Submersible Cable

(N)TSCGEWÖU Submersible Cables at 8.7/15kV and 12/20kV Ratings—Robust Solutions for Underwater Power Delivery in Mining, Dredging, and Pumps

(N)TSCGEWÖU - 8.7/15kV and 12/20kV Submersible Cable

Application | Flexible supply cable for permanent immersion in salty and brackish water up to 300 meters under high mechanical stresses. Suitable for pumps, dredges, floating docks, and trailing operations of opencast mining equipment. Suitable for indoor and outdoor applications. |

Voltage Rating Uo/U | 8.7/15kV, 12/20kV |

Test Voltage | 8.7/15kV: 24kV 12/20kV: 29kV |

Ambient Temperature | Fixed: -40°C to +80°C Flexed: -25°C to +60°C |

Maximum Permissible Water Temperature | +40°C |

Minimum Bending Radius | Fixed: 6 x overall diameter Flexed: 10 x overall diameter |

Phase Conductor | Class 5 tinned copper |

Insulation | Rubber compound |

Semi-Conductive Layers | Semi-conductive tape over the conductor and inner/outer semi-conductive rubber layer on the insulation |

Earth Conductor | Class 5 tinned copper |

Central Filler | Semi-conductive compound on a textile polyester support |

Inner Sheath | EPR rubber compound water proofing |

Outer Sheath | CM rubber compound water proofing |

Sheath Colour | Black |

Standards | VDE 0250 Part 813, HD 22.16, VDE 0295, EN 60228 Flame Retardant according to IEC/EN 60332-1-2 |

Construction Breakdown: Layers of Aquatic Armor

What elevates (N)TSCGEWÖU submersible cables to legendary status is their multi-layered build, akin to a high-tech onion tailored for submersion. At the core: Class 5 tinned copper phase and earth conductors. Tinning—coating with tin—wards off corrosion in saline assaults, while Class 5 stranding (fine wires twisted flexibly) absorbs vibrations from pumps or dredges without fatigue.

Encasing the conductor is a semi-conductive tape, followed by EPR (Ethylene Propylene Rubber) insulation—a rubber compound prized for dielectric strength and flexibility down to -25°C when flexed. Inner and outer semi-conductive rubber layers on the insulation shield against electrical trees (micro-cracks from field stress), ensuring longevity.

A central filler of semi-conductive compound on textile polyester support bulks the core, preventing collapse under pressure. The inner sheath, another EPR layer, provides waterproofing, blocking water ingress that could ionize and degrade insulation.

The outer sheath? CM (Chloroprene Monomer) rubber, black-hued for UV resistance and flame retardancy. This compound seals the deal with mechanical toughness, resisting abrasion from trailing over rocky seabeds.

This construction isn't just robust; it's synergistic. Semi-conductive layers equalize potentials, reducing partial discharges, while dual waterproofing (EPR inner, CM outer) meets IP68-equivalent submersion ratings. Flame retardancy per IEC/EN 60332-1-2 means no propagation in bundled fires—vital for mining shafts.

In essence, every layer serves a purpose: corrosion resistance, electrical integrity, flexibility, and environmental sealing. It's cable technology at its most resilient.

Why Choose (N)TSCGEWÖU Submersible Cables?

The advantages of 8.7/15kV and 12/20kV (N)TSCGEWÖU cables ripple through safety, efficiency, and economics. Foremost: unparalleled durability in hostile waters. Permanent immersion up to 300m with high mechanical stress means fewer replacements, slashing downtime in ops like subsea dredging where a snap could halt millions in output.

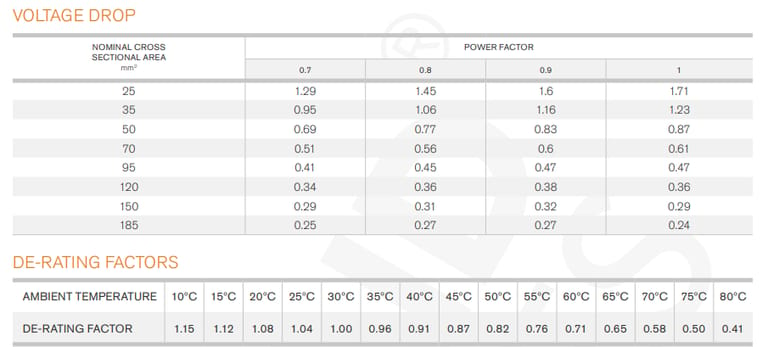

Electrical efficiency shines via low voltage drop—under 2% for most configs at unity power factor—minimizing energy loss and heat buildup. This translates to cooler operation, extending insulation life beyond 20 years in +40°C waters.

Flexibility is key: Class 5 stranding and rubber compounds allow tight bends (10x dia. flexed), ideal for reeling on mobile equipment. Tinned copper fights galvanic corrosion, outlasting bare alternatives in brackish zones.

Safety features abound: Semi-conductive shielding curbs shocks, while EPR/CM sheaths resist oils, chemicals, and flames. Standards compliance (VDE 0295, EN 60228) ensures global acceptance, reducing certification hurdles.

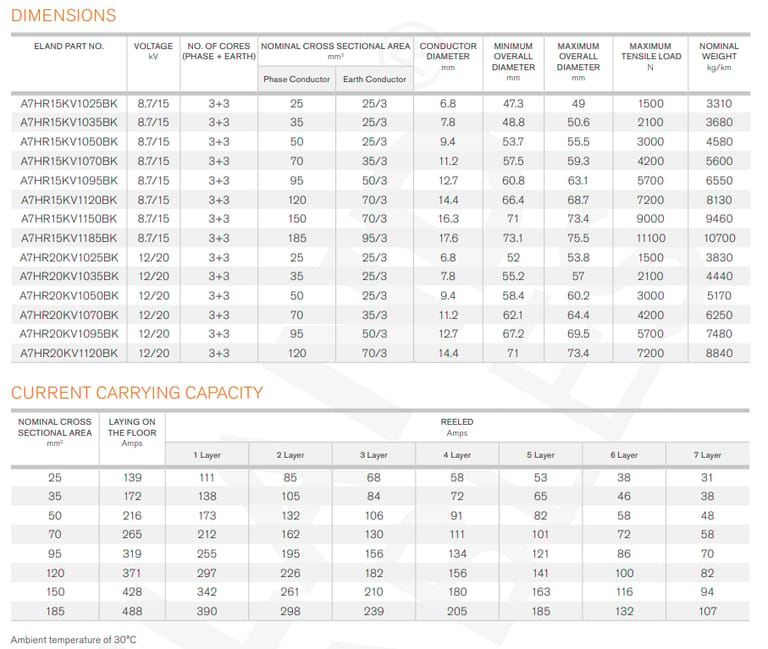

Economically, de-rating factors enable precise ampacity scaling—e.g., at 50°C ambient, 0.71 factor adjusts 25mm² to ~99A flat-laid, optimizing sizing without overspend. Lighter weights (vs. armored leads) ease installation, cutting logistics costs by 20-30% in remote sites.

Environmentally, these cables support sustainable practices: recyclable copper, low-emission rubber, and efficient power use align with green mining mandates. In sum, they deliver ROI through reliability, not fragility.

Usage Scenarios: From Docks to Depths

(N)TSCGEWÖU submersible cables thrive in scenarios demanding reliable power underwater. Primary: submersible pumps in mining dewatering. In flooded shafts, 8.7/15kV cables trail to 100HP motors, delivering 371A at 120mm² without excessive drop.

Dredging ops leverage 12/20kV variants for high-stress trailing—reeling over 500m while cutters grind sediment, their tensile strength (up to 11kN) preventing snaps.

Floating docks and offshore platforms use them for fixed immersion, powering cranes or lighting at -40°C winters to +80°C summers. Opencast mining trailers them behind excavators in shallow ponds, where brackish runoff tests waterproofing.

Indoor/outdoor versatility extends to wastewater plants or aquaculture, but their forte is harsh aquatics: think harbor pumps battling tidal surges or marine renewables feeding tidal turbines.

Current ratings guide selection—single-layer reeled for short hauls (139A at 25mm²), multi-layer for storage (31A). Always factor de-rating: in 60°C SA summers, scale down 29%.

The (N)TSCGEWÖU 8.7/15kV and 12/20kV submersible cables represent a pinnacle of cable technology—blending precision engineering with real-world grit. From their tinned cores to CM sheaths, every element combats the abyss's fury, delivering power where others falter. Benefits like low drop and high tensile strength, coupled with versatile scenarios from SA mines to global dredges, position them as essentials for aquatic industry.

As oceans warm and mining deepens, these cables will evolve, perhaps integrating smart sensors for predictive maintenance. For now, they remind us: in the face of depths, innovation floats the boat—or powers the pump. Dive in, and let reliability lead.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430