Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTSKCGERLOEU Medium-Voltage Coal Cutter Cable VDE 0250 Part 813

Revolutionizing Underground Mining: NTSKCGERLOEU Resilient Cables Ensure Continuous Power in Harsh Environments

NTSKCGERLOEU Medium-Voltage Coal Cutter Cable VDE 0250 Part 813

Applications | These cables are used for the connection of mobile electrical equipment inunderground mines, e.g. for coal-cutting machines,especially for the use in bretby chains with extremebending loads under low tensile stress. |

Standards | VDE 0250 Part 813 |

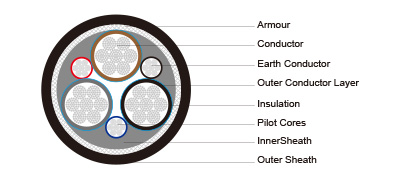

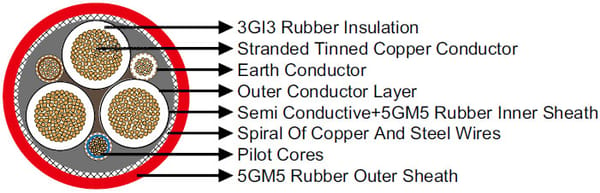

Construction  | |

Conductors | Flexible stranded tinned copper conductor. |

Insulation | Heatresistant3GI3 rubber based on EPR. |

Outer Conductor Layer (for 3.6/6kV) | Easy strippable outer conductive layer. |

Pilot Cores | Copper/steel conductor capable ofexpansion and compression with EPR rubber insulation. |

Earth Conductor | Spiral of tinnedcopper wires and a conductive tape. |

InnerSheath | 2 layer design, semi conductive rubber + Rubber type 5GM5. |

Armour | Spiral of steel wires,embedded in the outer sheath, fiberglas tape which preventssheath exchanging. |

Outer Sheath | Rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

1.8/3 (3.6) kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×35+3×(1.5ST+25/3)+UEL | 44.0 | 49.0 | 3900 |

3×50+3×(1.5ST+25/3)+UEL | 50.0 | 55.0 | 5100 |

3×70+3×(1.5ST+35/3)+UEL | 52.0 | 56.0 | 6200 |

3×95+3×(1.5ST+50/3)+UEL | 58.0 | 62.0 | 7500 |

3×120+3×(1.5ST+70/3)+UEL | 64.0 | 70.0 | 9350 |

3.6/6 (7.2) kV

Number of Cores×Nominal Cross Section | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

3×35+3×(1.5ST+25/3)+UEL | 49.0 | 54.0 | 5800 |

3×50+3×(1.5ST+25/3)+UEL | 56.0 | 61.0 | 6100 |

3×70+3×(1.5ST+35/3)+UEL | 57.0 | 62.0 | 6700 |

3×95+3×(1.5ST+50/3)+UEL | 62.0 | 66.0 | 8000 |

3×120+3×(1.5ST+70/3)+UEL | 67.0 | 71.0 | 10200 |

South Africa’s mining industry, a cornerstone of the nation’s economy, operates in some of the world’s most challenging environments. Deep underground, where abrasive surfaces, extreme temperatures, and high mechanical stress are the norm, reliable power delivery is critical. Enter the NTSKCGERLOEU Medium-Voltage Coal Cutter Cable, a game-changing solution designed to ensure continuous power in the harshest underground mining conditions. Built to VDE 0250 Part 813 standards, this resilient cable combines durability, flexibility, and advanced safety features to meet the demands of modern mining operations.

Key Benefits of the NTSKCGERLOEU Cable

The NTSKCGERLOEU cable offers a range of benefits that make it indispensable for South Africa’s mining industry:

Exceptional Durability

The cable’s abrasion-resistant outer sheath and reinforced steel wire armour protect against wear from rough surfaces, falling debris, and mechanical strikes. This durability reduces maintenance costs and extends cable lifespan, even in South Africa’s deepest mines.Superior Flexibility

With a minimum bending radius of 6x the outer diameter, the cable navigates tight spaces and complex layouts with ease. This flexibility simplifies installation, reduces stress on connectors, and ensures reliable performance during frequent equipment movements.Enhanced Safety Features

Safety is paramount in underground mining, where fire hazards and poor visibility pose significant risks. The cable’s flame-retardant and low-smoke properties, compliant with IEC 60332, minimize fire risks and toxic emissions, protecting workers in confined spaces.Optimal Electrical Performance

The cable’s high-conductivity copper conductors and shielding reduce voltage drops and electrical interference, ensuring efficient power delivery to heavy machinery. This efficiency translates to lower energy costs and reliable operation of critical equipment.Resilience to Mechanical Stress

The cable’s reinforced outer layers and robust construction withstand constant vibrations, bending, and pulling forces, making it ideal for dynamic applications like coal-cutting machines.

Applications in South Africa’s Mining Industry

South Africa’s mining sector, contributing significantly to GDP, relies on advanced technology to maintain global competitiveness. The NTSKCGERLOEU cable supports a variety of applications in this context:

Powering Mobile Equipment: In coal mines, such as those in Mpumalanga, the cable powers coal-cutting machines subjected to constant movement and abrasion. Its flexibility and durability ensure continuous operation without failure.

Fixed Installations: In gold and platinum mines, like those in the Witwatersrand Basin, the cable supports heavy machinery and ventilation systems, withstanding vibrations and impacts.

Deep Mining Operations: In ultra-deep mines, such as those reaching depths of over 4 km, the cable’s pressure-resistant design ensures performance under extreme conditions.

Ventilation and Pumping Systems: The cable’s high electrical capacity supports critical systems, reducing energy loss and ensuring reliable operation in high-humidity environments.

Case Study: Enhancing Efficiency in South Africa’s Coal Mines

Background: A leading coal mining company in South Africa’s Mpumalanga province faced frequent cable failures due to abrasive conditions and mechanical stress in its underground operations. These failures led to costly downtime and safety concerns.

Solution: The company partnered with Feichun to deploy the NTSKCGERLOEU cable, customized for its coal-cutting machines and ventilation systems. The cable’s abrasion-resistant jacket and flexible design were tailored to the mine’s specific environmental challenges.

Outcome:

50% Reduction in Downtime: The cable’s durability eliminated frequent replacements, boosting operational uptime.

Improved Safety: The flame-retardant and low-smoke properties enhanced worker safety, aligning with South Africa’s stringent mining regulations.

Cost Savings: Maintenance costs dropped by 35%, allowing the company to reinvest in operational improvements.

This case study highlights how the NTSKCGERLOEU cable addresses current challenges in South Africa’s coal mining sector, where operational efficiency and safety are critical amidst rising energy costs and regulatory pressures.

Installation and Maintenance Best Practices

To maximize the performance and lifespan of the NTSKCGERLOEU cable, mine operators should follow these best practices:

Installation in Tight Spaces: Avoid sharp bends and maintain the minimum bending radius of 6x the outer diameter to prevent damage. Use cable guides to protect against abrasion.

High-Humidity Environments: Seal connections to prevent moisture ingress, which can degrade insulation over time.

Prolonged Use Under Load: Regularly inspect cables for signs of wear, overheating, or insulation damage, especially in high-load applications like pumping systems.

Heavy Vibrations: Secure cables with additional supports in high-vibration zones to minimize mechanical stress.

Routine Maintenance: Conduct periodic checks to ensure compliance with IEC 60332 and VDE standards, and replace any cables showing signs of wear to prevent failures.

By adhering to these practices, operators can ensure the cable’s longevity and reliability, reducing downtime and maintenance costs.

The NTSKCGERLOEU Medium-Voltage Coal Cutter Cable is a cornerstone of reliable power delivery in South Africa’s underground mining industry. Its exceptional durability, flexibility, and safety features make it an ideal choice for powering coal-cutting machines, ventilation systems, and other critical equipment. By addressing challenges like abrasion, fire hazards, and extreme pressures, this cable ensures continuous operation, enhances safety, and reduces costs. As South Africa’s mining sector navigates economic and environmental challenges, the NTSKCGERLOEU cable stands out as a vital tool for driving efficiency and sustainability.

For mine operators seeking a proven solution, Feichun offers customized NTSKCGERLOEU cables tailored to specific operational needs. Contact Feichun today to learn how this resilient cable can power your mining operations through the toughest underground challenges.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430