Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

(N)TSKCGEWÖU Flexible Reeling Cable

How Advanced (N)TSKCGEWÖU Flexible Reeling Cables are Revolutionizing High-Stress Mining Operations

(N)TSKCGEWÖU Cable

Application | Flexible reeling cable with reduced weight and dimensions for high and extreme mechanical stresses (e.g., torsional stress, deflection into different planes, high reeling speed). Usable for reeling applications in underground and opencast mining. |

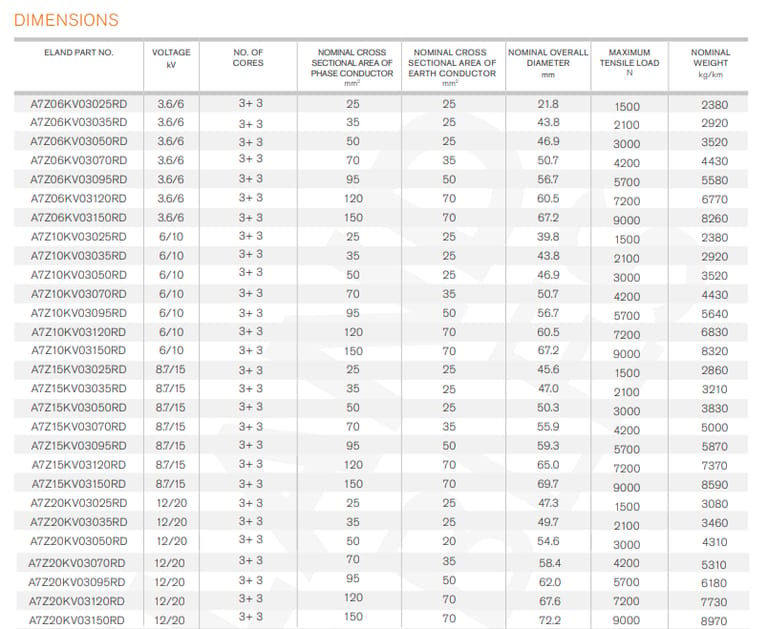

Voltage Rating Uo/U | 3.6/6kV, 6/10kV, 8.7/15kV, 12/20kV |

Test Voltage | 3.6/6kV: 11kV |

Maximum Torsional Stress | ± 25°/m |

Maximum Tensile Load | 30N/mm² |

Maximum Working Speed | 240m/min |

Temperature Rating | Maximum Short-Circuit Temperature: 250°C |

Minimum Bending Radius | Fixed: 6x overall diameter |

Phase Conductor | Class 5 Flexible Tinned Copper |

Insulation | Rubber Compound (Phase Conductor only) |

Semi-Conductive Layers | Semi-conductive insulation, tape over conductor, inner and outer semi-conductive rubber layer on insulation (Phase Conductor only) |

Earth Conductor | Class 5 Flexible Tinned Copper Conductor |

Central Filler | Semi-conductive compound |

Fibre Optics | 50/125 Multimode, 62.5/125 Multimode, 9/125 Singlemode |

Inner Sheath | Rubber Compound |

Anti-twist Element | Polyester braid |

Outer Sheath | Rubber Compound |

Outer Sheath Colour | Red |

Standards | Based on DIN VDE 0250 Part 813, VDE 0295 (IEC 60228), VDE 0207 Part 20 & Part 21, IEC 60811-404, IEC 60811-403, IEC 60332-1-2, ISO 4892-2, Special Reeling Test |

Decoding the (N)TSKCGEWÖU: A Primer on Flexible Reeling Cable Technology

At its core, the (N)TSKCGEWÖU is a high-voltage flexible reeling cable tailored for environments where standard cables would snap like twigs. The nomenclature breaks down to its German-inspired roots: "N" for rubber-insulated, "TSK" for heavy-duty flexible, "CGE" indicating copper conductors with earth and control elements, "WÖU" for weather- and oil-resistant outer sheathing. It's the go-to for reeling applications in underground and opencast mining, where machines like shuttle cars, continuous miners, and overhead cranes demand power without the drag of bulky, failure-prone lines.

What sets it apart in cable technology? Traditional mining cables often succumb to "corkscrewing"—a twisting failure from repeated reeling that leads to insulation breaches and shorts. The (N)TSKCGEWÖU counters this with a maximum torsional stress tolerance of ±25°/m and a reeling speed up to 240 m/min, making it ideal for dynamic, high-stress setups. Its voltage ratings—spanning 3.6/6kV to 12/20kV—cater to everything from portable tools to massive haul trucks, ensuring safe power delivery in hazardous zones.

In South Africa, where the Mining Charter emphasizes safety and sustainability, this cable aligns perfectly. Compliant with DIN VDE 0250 Part 813 and IEC standards, it meets SANS (South African National Standards) equivalents for flame retardancy (IEC 60332-1-2) and environmental resistance (ISO 4892-2). But specs alone don't tell the tale; let's crunch the numbers.

Installation Recommendations: Laying the Foundation for Longevity

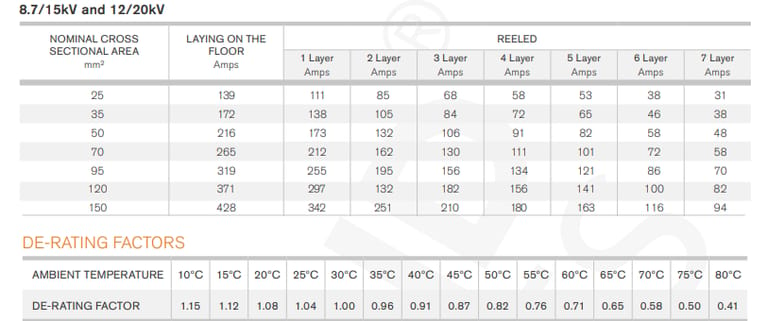

Installing a (N)TSKCGEWÖU cable demands precision to harness its full potential. Start with site assessment: ensure ambient temps stay within -30°C to +90°C, and avoid exposure to sharp edges or excessive vibration beyond spec. For reeling drums, mount at least 10x the cable's diameter from bends, using non-abrasive guides to distribute load evenly.

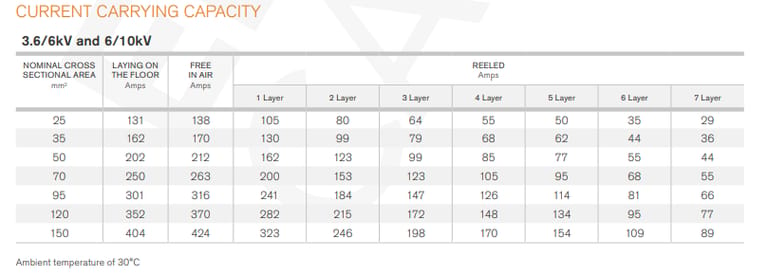

In South African opencast mines, where dust storms rage, secure with SANS-compliant hooks or clamps every 1-2 meters, preventing sags that amplify tensile stress (max 30N/mm²). Underground? Ventilate to dissipate heat, derating currents by 10-15% in humid shafts. Always torque terminations to manufacturer specs—overtightening crushes insulation, undertightening invites arcs.

Pro tip: Integrate fiber optics during install for real-time diagnostics, reducing unplanned outages by up to 40%. Follow VDE 0295 for conductor sizing, and test post-install with the cable's rated voltage (e.g., 17kV for 6/10kV models) to verify integrity.

Usage Scenarios: From Depths to Surface in Mining Cable Applications

The (N)TSKCGEWÖU shines in reeling for mobile machinery: powering longwall shearers in coal seams or shuttle cars in gold reefs. In opencast ops, it feeds electric shovels at 12/20kV, handling 240 m/min speeds without falter. Torsional resilience suits multi-plane deflections in tunneling, while earth conductors ensure fault protection in explosive atmospheres.

Beyond mining, it's adaptable for port cranes or wind turbine maintenance—anywhere high-voltage flexibility meets stress.

The (N)TSKCGEWÖU flexible reeling cable isn't just a conduit—it's the vein pulsing life into South Africa's mining arteries. From specs that defy extremes to constructions that bend but never break, it promises a safer, more efficient tomorrow. As the industry eyes electrification and automation, embracing this cable technology will be key. Whether in the platinum pits of the Bushveld or coal veins of Mpumalanga, the (N)TSKCGEWÖU stands ready to reel in progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430