Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

NTSWOEU 0.6/1kV E-Loader Cable VDE 0250 Part 813

NTSWOEU 0.6/1kV E-Loader Cable: Suitable for extreme bending loads, high tensile stress, and impact and crushing loads.

Applications | These cables are used for the connection of mobile machines under extremelyhigh mechanical loads, predominantly in miningsituations,also can beoperated via guide pulleys (cable cars) or used as areeling cable (LHD), suitable for extreme bending loads, high tensile stress,and impact and crushing loads. |

Standards | VDE 0250 Part 813 |

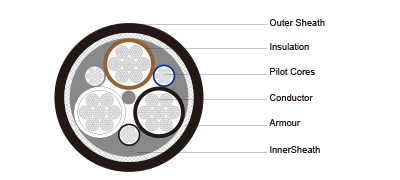

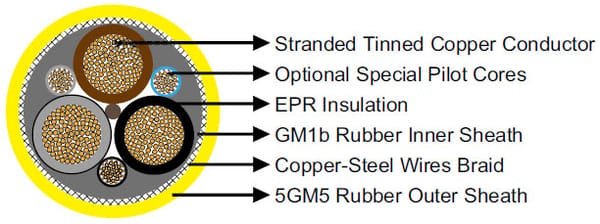

Construction | |

Conductors | Flexible stranded tinned copper conductor, class 6 according to DIN VDE 0295. |

Insulation | EPR. |

Pilot Cores (optional) | Special conductor,tinnedcopper braid and galvanised steel wire braid. |

InnerSheath | Rubber type GM1b. |

Armour/Earth Conductor | Concentric earth conductor as tensile-stress-resistant braided armour of combined copper-steel wires. |

Outer Sheath | Chlorinatedrubbe type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

Number of Cores×Nominal Cross Section | Insulation Thickness | Thickness of Inner Sheath | Thickness of Outer Sheath | Nominal Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | mm | mm | kg/km |

3x50/25KON + 3xST | 2.0 | 3.0 | 5.0 | 56 | 4950 |

The NTSWOEU 0.6/1kV E-Loader Cable is specifically engineered for demanding mining operations, making it a reliable choice for companies that require both durability and safety in challenging environments. Its design offers a combination of mechanical strength, electrical efficiency, and compliance with safety standards.

Durability Under Stress

This cable provides exceptional resistance to mechanical stress factors such as bending, tensile forces, impact, and crushing. These properties significantly extend its service life, even in the harsh and abrasive conditions typical of underground and surface mining.

Environmental Resistance

The outer sheath is oil-resistant, flame-retardant, and resistant to abrasion and tearing. This ensures consistent performance in environments exposed to oil, fuel, and other flammable substances, making it especially suitable for mining sites where fire and chemical hazards are prevalent.

Flexibility and Conductivity

Constructed with Class 6 tinned copper conductors, the cable delivers excellent electrical conductivity while maintaining high flexibility. This combination prevents fatigue in applications requiring repeated movement, such as reeling or trailing, ensuring stable power transmission over time.

Safety Features

Equipped with a concentric earth conductor and braided armour, the cable enhances grounding reliability and offers protection against electrical faults. This design reduces the risks of short circuits and enhances overall operational safety.

Cost-Effectiveness

By reducing downtime and minimizing maintenance requirements, the cable contributes to operational efficiency. In industries such as South African mining, where equipment reliability directly impacts productivity, this translates into lower overall costs and improved output.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430