Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

PiMF/TiMF 150/250V Mica Tape + XLPE Insulated, LSOH (SHF1) Sheathed, Individual Screened Fire Resistant Instrumentation & Control Cables (Multipair/Multitriple)

Application | These cables are used on board of ships in all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352 in safety circuit, where fire resistance is required. These cables are fire resistant, flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

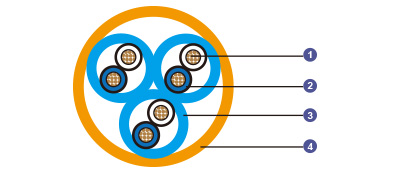

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | Mica tape + XLPE. |

Cabling Element | Pair/Triple. |

Individual Screen | Al/polyester tape. |

Drain Wire | Tinned copper wire. |

Outer Sheath | LSOH (SHF1). SHF2 can be offered upon request. |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD (OD>25mm); 4×OD (OD ≤25mm) |

Applications: Where Reliability Meets the High Seas

On board ships, the environment is unforgiving. Salt spray corrodes metals, vibrations from engines rattle components, and the confined spaces amplify risks. Yet, it's fire that poses one of the greatest dangers – a spark in an engine room can escalate into a blaze, threatening lives and assets. This is where PiMF/TiMF cables shine. These cables are specifically engineered for fixed installations in all ship locations not exposed to mechanical risk, complying with IEC 60092-352 standards for electrical installations in ships.

Primarily used in safety circuits, they ensure fire resistance where it's critical. Think of them as the nervous system of a vessel: transmitting signals for instrumentation and control systems that monitor everything from engine performance to fire detection. Their fire-resistant properties mean they can continue functioning even as flames rage, buying precious time for evacuation or firefighting. Moreover, these cables are flame retardant, emit low smoke, and are halogen-free – qualities that make them ideal for passenger ships and commercial vessels alike.

Why halogen-free? Halogens, like chlorine in some plastics, release toxic gases when burned, which can suffocate occupants in enclosed spaces. By using low smoke zero halogen (LSOH) materials, specifically SHF1 sheathing (with SHF2 available on request), these cables minimise smoke density and toxicity, aligning with international maritime safety protocols. In South African waters, where our ports handle everything from bulk carriers to luxury cruisers, such cables are indispensable. For instance, vessels docking in Durban or Cape Town must meet global standards to operate safely, and PiMF/TiMF cables help achieve that by reducing secondary hazards during fires.

From a broader perspective, their application extends beyond mere compliance. In an era of increasing ship sizes and automation, these cables support advanced systems like integrated bridge controls and remote monitoring. They're not armoured, so they're suited for areas without mechanical stress, but their individually screened design protects against electromagnetic interference (EMI), ensuring signal integrity in noisy electrical environments. This makes them versatile for both new builds and retrofits, contributing to the overall resilience of maritime infrastructure.

Standards: The Backbone of Trust and Performance

No engineering marvel stands alone; it's built on a foundation of standards that ensure consistency, safety, and interoperability. The PiMF/TiMF cables are no exception, adhering to a suite of International Electrotechnical Commission (IEC) norms that govern everything from construction to fire performance.

At the core are IEC 60092-350, -351, -376, and -359, which detail electrical installations in ships, including cable selection, insulation, and sheathing. These ensure the cables can handle the unique demands of marine environments, such as humidity and temperature fluctuations. Fire resistance is tested under IEC 60331-21, where cables must maintain circuit integrity for at least 90 minutes at 750°C – imagine a blowtorch assault, yet the cable soldiers on.

Flame retardancy comes via IEC 60332-1 (single cable) and IEC 60332-3-22 (bunched cables), simulating how fires spread in real scenarios. Low smoke emission is verified by IEC 61034, measuring smoke density to ensure visibility during emergencies. Halogen-free status is confirmed through IEC 60754-1/2, which tests for acidic gases that could corrode equipment or harm people.

These standards aren't arbitrary; they're the result of decades of international collaboration, influenced by incidents like the 2012 Costa Concordia disaster, where fire and electrical failures compounded the tragedy. In South Africa, our maritime regulations, aligned with the International Maritime Organization (IMO), mandate such compliance for ships under our flag or visiting our shores. By meeting these benchmarks, PiMF/TiMF cables not only prevent failures but also facilitate insurance approvals and international trade. From an analytical viewpoint, this multi-standard approach ensures holistic performance: electrical reliability under IEC 60092, fire endurance via 60331, and environmental safety through 60754/61034. It's a layered defence, much like a ship's watertight compartments.

Conclusion:

In wrapping up, PiMF/TiMF cables embody the fusion of science and engineering to combat maritime perils. Their applications safeguard lives, standards ensure global trust, construction delivers precision, properties guarantee endurance, and dimensions offer flexibility. As South Africa expands its blue economy, these cables will play a pivotal role in safer, more efficient shipping. Looking ahead, advancements in materials like bio-based LSOH could further enhance sustainability. Ultimately, these aren't just cables – they're the unsung heroes keeping our oceans navigable and secure.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430