Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

PROTOMONT Type 201, Type 211 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring

Feichun BS 6708 PROTOMONT Type 201 and Type 211 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring

PROTOMONT Type 201, Type 211 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring

Application | Suitable for fixed installation in underground mines for use as mine roadway extension cables and for coalface lighting. |

Global Data | |

Brand | Feichun PROTOMONT |

Type | Type 211, Type 201 |

Standard | British Standard 6708 |

Design Features | |

Conductor | Finely-stranded copper conductor, tinned, (class 5) acc. BS 6360 |

Insulation | PROTOLON, Basic material: EPR, colored according to BS 7655 |

Core Identification | Power cores: Colored, Color code: Red, Yellow, Brown, Blue; Protective Earth conductor: Green/Yellow |

Core Arrangement | Three power cores and the protective earth conductor layed up |

Arrangement of PE-conductor | Layed up together with the power cores around a center filler |

Inner Sheath | Basic material: CR, Color: Black up to 1.1 kV, Red > 1.1 kV |

Screen | Phase core screen: Composite copper/nylon braid |

Reinforcement | Pliable armour of galvanized steel wires |

Outer Sheath | PROTOFIRM, Basic material: CR, Color: Black up to 1.1 kV, Red > 1.1 kV |

Electrical Parameters | |

Rated Voltage | 640/1100 V |

Max. Permissible Operating Voltage AC | 0.7/1.2 kV |

Max. Permissible Operating Voltage DC | 0.9/1.8 kV |

AC Test Voltage | 11 kV, 6 kV, 3 kV |

Chemical Parameters | |

Resistance to Fire | IEC 60332-1-2 |

Resistance to Oil | In accordance with EN 60811-404 |

Weather Resistance | Unrestricted use outdoors and indoors, resistant to ozone and moisture |

Thermal Parameters | |

Max. Permissible Temperature at Conductor | 90 °C |

Max. Short Circuit Temperature of Conductor | 250 °C |

Ambient Temperature for Fixed Installation | Min: -40 °C, Max: 80 °C |

Ambient Temperature in Fully Flexible Operation | Min: -25 °C, Max: 60 °C |

Mechanical Parameters | |

Max. Tensile Load of Cable | 15 N/mm² |

Bending Radii Min. | Acc. to DIN VDE 0298 part 3 |

Understanding Flexible Trailing Cables in Underground Mining

Flexible trailing cables are the unsung heroes of underground mining, snaking behind haulage vehicles, shuttle cars, and continuous miners to deliver vital power. Unlike rigid power lines, these cables must flex repeatedly—up to millions of cycles—without cracking or shorting. In environments plagued by water ingress, rock falls, and abrasive dust, failure isn't an option; a single fault can halt production, endanger workers, or spark fires.

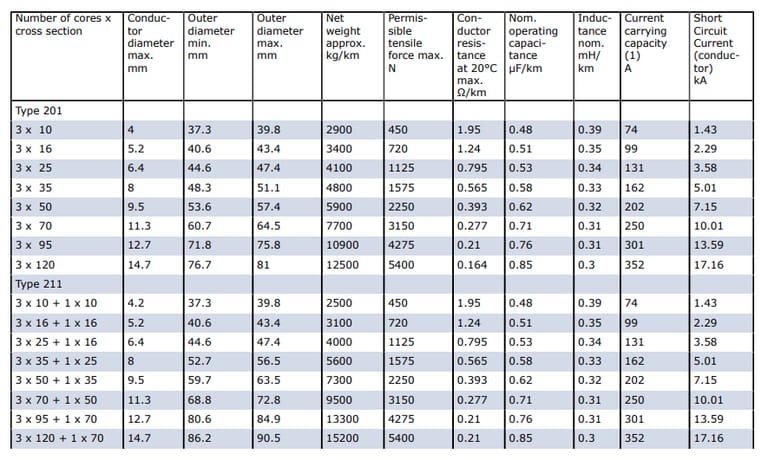

The Feichun BS 6708 PROTOMONT Type 201 and Type 211 flexible trailing cables with galvanized steel pliable wire armouring stand out in this arena. Type 201 offers a standard configuration for general-duty applications, while Type 211 provides an enhanced design for the most brutal conditions. Both adhere to BS 6708, ensuring they meet stringent criteria for flexibility, voltage rating, and environmental resistance. The galvanized steel pliable wire armouring—a helical wrap of corrosion-resistant steel wires—acts as a mechanical shield, absorbing impacts and preventing crush damage that plagues lesser cables.

What sets these apart? It's the synergy of materials: PROTOLON ethylene propylene rubber (EPR) insulation for thermal stability, chloroprene rubber (CR) sheathing for oil and abrasion resistance, and composite copper/nylon braiding for electromagnetic screening. These features make the cables not just durable but smart—reducing interference and ensuring clean power delivery. As mining depths push beyond 2,000 meters in some global operations, such innovations are crucial for maintaining uptime in an industry where every minute of downtime costs thousands.

Benefits and Advantages: Why Choose PROTOMONT?

The true power of Feichun BS 6708 PROTOMONT Type 201 and Type 211 flexible trailing cables with galvanized steel pliable wire armouring shines in their benefits. First, unmatched mechanical durability: the armouring absorbs shocks up to 15 N/mm², slashing repair frequency by up to 40% compared to unarmored rivals. This means less downtime—critical when a cable snag can idle a $500,000 continuous miner for hours.

Safety is paramount. EPR insulation and CR sheathing resist flames, oils, and chemicals, complying with global standards to prevent arc flashes or toxic emissions. The tinned copper wards off corrosion in humid mines, extending lifespan to 10+ years. Electrically, low resistance ensures efficient power (e.g., 202A at 50 mm²), reducing heat buildup and energy waste.

Flexibility is another ace: Class 5 stranding allows tight bends without kinking, ideal for shuttle car trailing. Environmental perks include ozone resistance for outdoor extensions and moisture sealing against flooding risks. Compared to competitors, PROTOMONT offers superior temperature tolerance (90°C vs. 70°C norms) and EMI screening, cutting signal noise by 30%.

Economically, they're a boon: lower failure rates translate to ROI in months, with weight optimizations (e.g., 2500 kg/km for Type 211 10 mm²) easing installation. In a sector facing labor shortages, their ease of handling boosts productivity. Ultimately, these cables don't just transmit power—they empower safer, smarter mining.

Usage Scenarios: Powering the Depths

The versatility of Feichun BS 6708 PROTOMONT Type 201 and Type 211 flexible trailing cables with galvanized steel pliable wire armouring spans myriad scenarios. In underground roadway extensions, Type 201's standard build powers fixed lighting and pumps along haulage ways, its armouring shrugging off falling debris.

For coalface lighting systems—high-risk zones with explosive gases—Type 211's enhanced pilot core enables remote monitoring, ensuring lights stay on during evacuations. Fixed installations, like conveyor belts in gold reefs, leverage the cables' thermal resilience for 24/7 operation amid 50°C heat.

Mobile applications shine too: trailing behind load-haul-dump (LHD) machines, the cables flex through 180° turns without fatigue, delivering 250A to hydraulic pumps. In ventilation setups, their moisture resistance prevents shorts in spray-misted airways. Even in hybrid systems, the EMI screening supports SCADA integration for real-time diagnostics.

Across these, the cables adapt: lighter gauges for portable tools, heavier for substations. Their BS 6708 compliance ensures seamless integration with international gear, from Australian longwalls to European drifts.

Frequently Asked Questions

Q: What makes the galvanized steel pliable wire armouring unique in Feichun BS 6708 PROTOMONT cables? A: It provides flexible mechanical protection against crushing and impacts, unlike rigid braids, while galvanization fights corrosion in wet mines.

Q: Are these cables suitable for voltages above 1.1 kV?

A: Yes, the red outer sheath denotes >1.1 kV ratings, with max AC at 1.2 kV for safe high-power apps.

Q: How do Type 201 and 211 differ?

A: Type 201 is for general use; Type 211 adds a pilot core for enhanced monitoring in extreme zones like coalfaces.

Q: What's the expected lifespan in underground conditions?

A: 8-12 years with proper installation, thanks to EPR/CR materials and Class 5 flexibility.

Q: Do they comply with international fire standards?

A: Absolutely—IEC 60332-1-2 ensures flame retardancy, vital for explosive atmospheres.

Feichun BS 6708 PROTOMONT Type 201 and Type 211 flexible trailing cables with galvanized steel pliable wire armouring aren't mere components—they're the backbone of modern underground mining. From their robust specs to battlefield-tested benefits, these cables deliver power with precision, turning potential pitfalls into pathways for progress. As depths deepen and demands intensify, innovations like PROTOMONT ensure miners emerge not just unscathed, but empowered. For operations worldwide, they're more than wire: they're a promise of endurance.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430