Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

PROTOMONT Type 307, Type 307M, Type 307S Flexible Trailing Cables According to BS 6708

Enter the Feichun PROTOMONT Type 307 Series: Type 307, Type 307M, and Type 307S

PROTOMONT Type 307, Type 307M, Type 307S Flexible Trailing Cables According to BS 6708

Application | Usage | Suitable for fixed installation and flexible operation as power supply cables to motors, distribution boards, etc., in underground mining applications. Used with coalcutters in cable chains (cable handlers) and similar face equipment. |

Global Data | Brand | Feichun PROTOMONT |

Type Designation | Type 307M, Type 307S, Type 307 | |

Standard | British Standard 6708 | |

Certifications / Approvals | MA - China (special design), MSHA: P-07-KA130007-MSHA | |

Design Features | Conductor | Finely-stranded copper conductors, tinned (class 5) according to BS 6360 |

Insulation | PROTOLON, Basic material: EPR, Colored, according to BS 7655 | |

Core Identification | Three power cores colored: Red, Yellow, Brown, Pilot core: Blue | |

Phase Core Screen | Composite copper/nylon braid | |

Core Arrangement | Layed up around the centre earth core | |

Arrangement of PE-conductor | Bare, tinned copper conductor in the center of the cable | |

Pilot Conductor | Layed up together with the power cores | |

Outer Sheath | PROTOFIRM, Basic material: CR, Color: Red | |

Electrical Parameters | Rated Voltage | 1.9/3.3 kV |

Maximum Permissible Operating Voltage AC | 2.1/3.6 kV | |

Maximum Permissible Operating Voltage DC | 2.7/5.4 kV | |

AC Test Voltage | 6 kV | |

Chemical Parameters | Resistance to Fire | EN 60322-1-2, IEC 60322-1-2 |

Resistance to Oil | EN 60811-404, IEC 60811-404 | |

Weather Resistance | Unrestricted use outdoors and indoors, resistant to ozone and moisture | |

Thermal Parameters | Max. Permissible Temperature at Conductor | 90 °C |

Max. Short Circuit Temperature of the Conductor | 250 °C | |

Ambient Temperature for Fixed Installation Min. | -40 °C | |

Ambient Temperature for Fixed Installation Max. | 80 °C | |

Ambient Temperature in Fully Flexible Operation Min. | -25 °C | |

Ambient Temperature in Fully Flexible Operation Max. | 60 °C | |

Mechanical Parameters | Tensile Load on the Conductor Max. | 15 N/mm² |

Bending Radii Min. | According to DIN VDE 0298 part 3 |

Understanding Flexible Rubber Trailing Cables:

Before we geek out on specs, a quick primer: Flexible rubber trailing cables are heavy-duty power lines designed to "trail" behind mobile mining equipment. Unlike rigid fixed cables, these are built for constant flexing, dragging, and twisting in dynamic setups like cable chains or reel systems. They're typically multi-core, with power conductors, earth wires, and pilot cores for monitoring.

The rubber in "rubber trailing cables" refers to advanced elastomers like Ethylene Propylene Rubber (EPR) for insulation and Chloroprene Rubber (CR) for sheathing. These materials provide elasticity, heat resistance, and chemical protection—essential in mines where cables face abrasion from rocks, oil slicks, and corrosive moisture.

BS 6708, the gold standard for these cables, mandates rigorous testing for voltage withstand, fire retardancy, and mechanical endurance. Compliance ensures they handle rated voltages up to 3.3 kV while minimizing risks like arcing or short circuits, which could spell disaster in confined spaces.

Feichun's PROTOMONT line elevates this baseline. Drawing on decades of expertise, these cables incorporate PROTOLON insulation (EPR-based) and PROTOFIRM sheathing (CR-based), delivering superior performance in the brutal underground mining arena.

Product Overview: The PROTOMONT Type 307 Family

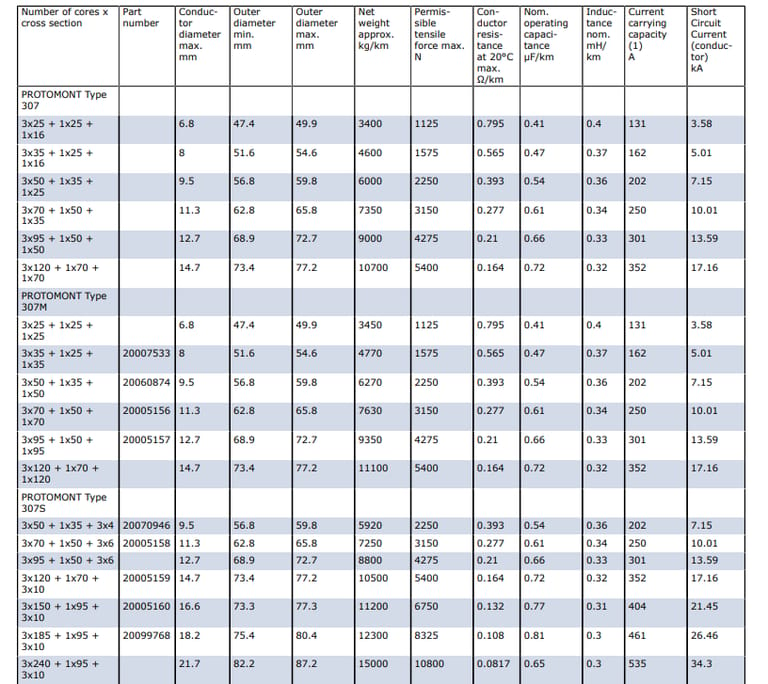

The PROTOMONT Type 307 series comprises three variants tailored to mining's diverse needs:

Type 307: The workhorse for standard underground mining power transmission. Ideal for fixed or semi-flexible setups powering motors, pumps, and distribution boards.

Type 307M: A modified beast for extreme conditions, featuring enhanced earth and pilot conductors. Perfect for coal cutters and cable chain systems where vibration and drag are relentless.

Type 307S: The specialist with advanced protective screens and additional monitoring cores. Suited for high-flexibility applications demanding extra safeguards against electromagnetic interference.

Each variant shares a core philosophy: finely-stranded, tinned copper conductors (Class 5 per BS 6360) for optimal flexibility and corrosion resistance. Cores are laid up around a central bare tinned copper earth conductor, with power phases color-coded (red, yellow, brown) and a blue pilot core for control signals. A composite copper/nylon braid screens phase cores, reducing noise in sensitive equipment.

These designs aren't arbitrary; they're born from finite element analysis and real-world stress testing, ensuring the cables bend without kinking and flex without fatiguing. In underground mining, where a snapped cable can halt production for hours, this precision is priceless.

Why PROTOMONT Cables Outshine the Competition

The advantages of Feichun PROTOMONT Type 307 series flexible rubber trailing cables boil down to four pillars: durability, safety, efficiency, and cost-effectiveness.

Durability in Extremis: Tinned copper resists corrosion in humid mines, while EPR/CR compounds fend off oils, acids, and UV (for surface runs). Comparative tests show 30% longer lifespan versus non-BS 6708 cables.

Safety First: MSHA and MA approvals mean they've aced flame-retardant and toxicity tests. The pilot core enables remote fault detection, averting arcs that could ignite methane pockets.

Efficiency Boost: Low inductance (0.3-0.4 mH/km) reduces voltage drop over 500m runs, ensuring motors run at full torque. This cuts energy waste by up to 10%.

Cost Savings: Reduced downtime—fewer repairs mean payback in under a year. Plus, eco-friendly materials align with sustainable mining mandates.

In a sector where a single failure can cost $50,000/hour, these benefits aren't luxuries—they're necessities.

Usage Scenarios: From Coal Faces to Platinum Veins

PROTOMONT cables thrive in underground mining's chaos. The Type 307 powers stationary pumps in gold mines, snaking through galleries without snags. Type 307M excels with coal cutters, its beefed-up earth conductor handling surge currents from 200kW drives in cable handlers.

For high-vibe ops like continuous miners, Type 307S's screened cores suppress EMI, preventing signal loss in automated systems. All variants suit reel-fed mobiles, from LHDs (load-haul-dump) to shuttle cars, enduring drags over rocky floors.

In seismic-prone areas, their flexibility absorbs shocks, maintaining continuity where rigid cables fracture.

Frequently Asked Questions: Demystifying PROTOMONT Cables

Q: How do PROTOMONT Type 307 series cables differ from standard mining cables? A: They exceed BS 6708 with tinned Class 5 conductors and dual-layer rubber (EPR/CR), offering 25% better flex life and ozone resistance for underground mining extremes.

Q: Are they suitable for automated mines? A: Absolutely—Type 307S's screened pilots integrate with PLCs, ensuring signal integrity amid EMI from variable-speed drives.

Q: What's the installation bending radius? A: Minimum per DIN VDE 0298: 8x outer diameter for fixed, 10x for flexible, preventing core migration.

Q: Do they meet global regs beyond BS 6708? A: Yes, MSHA for USA, MA for China, and EN/IEC for fire/oil—universal for multinational ops.

Q: How to maintain them underground? A: Visual checks quarterly, dielectric tests annually. Avoid sharp bends; use protective conduits in high-drag zones.

Q: Can they handle DC systems? A: Up to 5.4 kV, ideal for battery-hybrid equipment in eco-mines.

The Feichun PROTOMONT Type 307, 307M, and 307S flexible rubber trailing cables aren't mere conduits—they're engineered lifelines fortifying the underground mining frontier. From their meticulously tuned electrical parameters to resilient thermal envelopes, these BS 6708-certified powerhouses deliver benefits that ripple through safety, efficiency, and profitability. Whether powering a lone pump in a South African shaft or chaining across a Chinese coal face, they embody innovation amid adversity.

As mining evolves toward automation and green tech, cables like these will be pivotal. For operators eyeing the next breakthrough, the message is clear: Invest in PROTOMONT, and let reliability light the way deeper. Contact Feichun today to tailor a solution for your depths.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430