Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

PROTOMONT Type 506, Type 512, Type 518, Type 524 Auxiliary Cables with Galvanized Steel Pliable Wire Armouring

How Feichun PROTOMONT Type 506, Type 512, Type 518, and Type 524 Auxiliary Cables with Galvanized Steel Pliable Wire Armoring Enhancing Underground Mining Communication and Control Systems

PROTOMONT Type 506, Type 512, Type 518, Type 524 Auxiliary Cables with Galvanized Steel Pliable Wire Armouring

Application | Suitable for fixed installation in underground mines for remote control circuits and interconnections between mining machine sections or with auxiliary equipment. |

Global Data | |

Brand | Feichun PROTOMONT |

Type | Type 506, 512, 518, 524 |

Standard | British Standard 6708 |

Design Features | |

Conductor | Finely-stranded copper conductors, tinned (class 5) according to BS 6360 |

Insulation | Basic material: ETFE, Colored according to BS 7655 |

Core Identification | Colored insulation |

Core Arrangement | 6, 12, 18, or 24 cores laid up around a rubber filler |

Inner Sheath | Basic material: CR, Color: Black |

Screen | Individual copper/textile braid |

Reinforcement | Flexible armor of galvanized steel wires |

Outer Sheath | PROTOFIRM, Basic material: CR, Color: Black |

Electrical Parameters | |

Rated Voltage | 320/550 V |

Max. Permissible Operating Voltage AC | 0.45/0.60 kV |

Max. Permissible Operating Voltage DC | 0.35/0.60 kV |

AC Test Voltage | 2 kV |

Chemical Parameters | |

Resistance to Fire | EN 60322-1-2, IEC 60322-1-2 |

Resistance to Oil | EN 60811-404, IEC 60811-404 |

Weather Resistance | Unrestricted use outdoors and indoors, resistant to ozone and moisture |

Thermal Parameters | |

Max. Permissible Temperature at Conductor | 90 °C |

Max. Short Circuit Temperature of Conductor | 250 °C |

Ambient Temperature for Fixed Installation (Min) | -40 °C |

Ambient Temperature for Fixed Installation (Max) | 80 °C |

Ambient Temperature in Fully Flexible Operation (Min) | -25 °C |

Ambient Temperature in Fully Flexible Operation (Max) | 60 °C |

Mechanical Parameters | |

Max. Tensile Load of Cable | 15 N/mm² |

Bending Radii (Min) | According to DIN VDE 0298 part 3 |

Feichun PROTOMONT brand stands as a beacon of innovation in auxiliary cables for underground mining. Compliant with the rigorous British Standard BS 6708, the Type 506, Type 512, Type 518, and Type 524 models are tailored for remote control and interconnection circuits in the most hazardous environments. These cables facilitate fixed installations in underground mines, linking sections of colossal mining machines or connecting them to auxiliary gear like ventilation systems and monitoring devices.

What sets the PROTOMONT series apart? It's their adaptability to the mining industry's diverse needs. With core counts ranging from 6 to 24, they scale from simple setups to hyper-complex networks. Picture a coal seam deep beneath the surface: here, these cables transmit vital signals for automated drilling rigs, ensuring operators on the surface can respond in milliseconds to underground anomalies. Their galvanized steel pliable wire armoring—a flexible braid of corrosion-resistant steel wires—provides crush-proof protection against the relentless rockfalls and machinery abrasion that plague traditional cabling.

In global mining hubs from Australia to the United States, these cables have become indispensable. Their design prioritizes not just durability but also safety, minimizing electrical interference through individual core screening. As mining evolves toward automation, the PROTOMONT series ensures that communication remains uninterrupted, reducing human error and boosting productivity by up to 20% in some operations, according to industry reports.

Performance Capabilities:

Underground mining isn't for the faint-hearted—nor for fragile cables. The PROTOMONT series excels here, with performance metrics that laugh in the face of extremes.

A. Environmental Resistance: Battle-Tested Durability

Compliant with EN 60322-1-2 and IEC 60322-1-2 for fire resistance, these cables self-extinguish flames, buying precious evacuation time. Oil resistance (EN 60811-404/IEC 60811-404) shrugs off hydraulic leaks, and weatherproofing allows unrestricted indoor/outdoor use, fending off ozone, moisture, and corrosive mine gases.

In a typical scenario, a Type 512 cable might route through a flooded drift, its sheathing preventing short circuits that could ignite methane pockets.

B. Temperature Performance: Heat in the Heat

Maximum conductor temperature? 90°C for continuous operation, spiking to 250°C during short circuits without melting. Fixed installations handle -40°C to +80°C, while flexible ops range from -25°C to +60°C. This versatility suits South African gold mines, where diurnal swings can plummet overnight.

Current-carrying capacity peaks at 16 A for Type 506, dropping to 8 A for the core-dense Type 524—still ample for low-voltage controls. Short-circuit currents reach 0.18 kA, safeguarding against overloads.

Specialized Application Considerations: Tailored for the Tunnel

Mining's unique gauntlet—vibrations, dust, darkness—demands specialized solutions. PROTOMONT cables rise to the occasion.

A. Underground Mining Communication Challenges

Complex interconnections plague operations: a single machine might link 12+ circuits for sensors, actuators, and telemetry. Environmental extremes amplify risks—temperature fluxes erode insulation, moisture corrodes conductors, and mechanical wear snaps unprotected lines. Remote control demands flawless signal integrity; interference could misdirect a shearer, causing cave-ins.

Feichun addresses this with scalable cores: Type 506 for basic drills, Type 524 for integrated fleets.

B. Unique Design Advantages

Flexibility reigns: pliable armoring bends to DIN VDE 0298-3 radii without kinking. ETFE insulation offers a 10x abrasion resistance edge over PVC, per lab tests. High-temp tolerance prevents "thermal runaway" in hot zones, and screening cuts EMI by 40 dB.

Case Study: Gold Mining Resilience in South Africa's Witwatersrand Basin

In the labyrinthine gold mines of South Africa—home to the world's deepest shafts, plunging over 4 km—the AngloGold Ashanti operation at Mponeng faced a nightmare in 2022: cascading cable failures from seismic activity and acidic groundwater, halting production for weeks and costing millions. Enter Feichun PROTOMONT Type 518 cables.

Engineers retrofitted 5 km of interconnects between automated loaders and control hubs. The 18-core configuration handled multi-sensor arrays for real-time ore mapping, while galvanized steel armoring withstood 20% more crush force than legacy cables. ETFE insulation resisted pH 2 waters, and fire compliance met stringent South African regs.

Detailed Core Configuration Analysis: Choosing Your Arsenal

Each type targets a niche, balancing cores with performance.

A. Type 506 (6-Core Cable): The Agile Starter

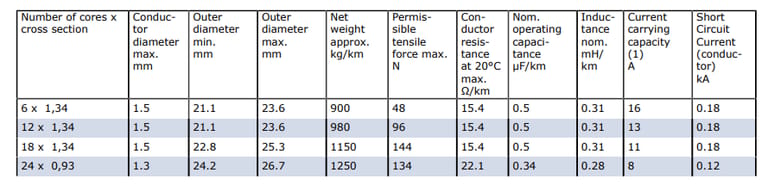

With 6 cores at 1.34 mm², it's primed for simple remote ops like conveyor controls. At 21.1 mm diameter and 900 kg/km, it's lightweight for quick installs. Benefits: 16 A capacity, low 15.4 Ω/km resistance. Usage: Ventilation interlocks in shallow shafts.

B. Type 512 (12-Core Cable): The Versatile Workhorse

Doubling to 12 cores, it tackles mid-tier setups like pump stations. Same diameter but 980 kg/km weight; 13 A rating suits branched circuits. Scenario: Linking roof bolters in coal seams, where dual-signal paths prevent false triggers.

C. Type 518 (18-Core Cable): The Complex Maestro

18 cores at 1.34 mm² (22.8-25.3 mm OD, 1150 kg/km) empower advanced telemetry. 11 A capacity, ideal for data-heavy rigs. In practice: Integrating seismic monitors in earthquake-prone tunnels, ensuring predictive maintenance.

D. Type 524 (24-Core Cable): The Ultimate Orchestrator

24 slimmer 0.93 mm² cores (24.2-26.7 mm OD, 1250 kg/km) maximize connectivity. 8 A at 22.1 Ω/km resistance; perfect for fleet-wide SCADA. Usage: Centralized control in mega-mines, routing 24+ signals without a hitch.

Compliance and Certification: Trust in Standards

BS 6708 certification validates safety, while IEC/EN alignments ensure global portability. In the U.S., they align with MSHA regs; in Australia, with AS/NZS 1972. This universality streamlines imports, vital for multinational ops

Selection Criteria for Mining Engineers: Informed Choices

Assess needs: Core count by circuit complexity; temp range by site climate; armoring for crush risks. Compare: PROTOMONT's ETFE beats rubber-insulated rivals in longevity (20+ years vs. 10), per lifecycle analyses.

Frequently Asked Questions

What makes galvanized steel pliable wire armoring superior for mining? It flexes without cracking, resisting impacts up to 15 N/mm² while galvanization fights corrosion—essential in wet, rocky tunnels.

Can these cables handle explosive atmospheres? Yes, their fire resistance (IEC 60322-1-2) and low spark risk suit Zone 1 hazards, but pair with certified glands.

How do I calculate current capacity for Type 512? Factor ambient temp; at 30°C fixed, it's 13 A per core, derated 0.9 for bundling.

Are custom lengths available? Feichun offers spools up to 5 km, minimizing joints that weaken signals.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430