Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

PROTOMONT Type 62, Type 63, Type 64 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring

Feichun BS 6708 PROTOMONT Type 62, Type 63, and Type 64 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring Delivering Unmatched Reliability in Underground Mining

PROTOMONT Type 62, Type 63, Type 64 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring

Application | Suitable for fixed installation in underground mines as roadway extension cables and coalface lighting |

Global Data | |

Brand | Feichun PROTOMONT |

Type | Type 62, 63, 64 |

Standard | British Standard 6708 |

Design Features | |

Conductor | Finely-stranded copper conductor, tinned, (class 5) acc. BS 6360 |

Insulation | PROTOLON, Basic material: EPR, colored according to BS 7655 |

Core Identification | Power cores: Colored (Red, Yellow, Brown), Earth conductor: Green/Yellow; Type 62: Brown, Blue; Type 63: Red, Brown, Blue; Type 64: Red, Yellow, Brown, Blue |

Core Arrangement | Three power cores and protective earth conductor layed up |

Arrangement of PE-Conductor | Layed up with power cores around a center filler |

Inner Sheath | Basic material: CR, Color: Black |

Screen | Phase core screen: Composite copper/nylon braid |

Reinforcement | Pliable armour of galvanized steel wires |

Outer Sheath | PROTOFIRM, Basic material: CR, Color: Black |

Electrical Parameters | |

Rated Voltage | 640/1100 V |

Max. Permissible Operating Voltage AC | 0.7/1.2 kV |

Max. Permissible Operating Voltage DC | 0.9/1.8 kV |

AC Test Voltage | 3 kV |

Chemical Parameters | |

Resistance to Fire | IEC 60332-1-2 |

Resistance to Oil | In accordance with EN 60811-404 |

Weather Resistance | Unrestricted use outdoors and indoors, resistant to ozone and moisture |

Thermal Parameters | |

Max. Permissible Temp. at Conductor | 90 °C |

Max. Short Circuit Temp. of Conductor | 250 °C |

Ambient Temp. for Fixed Installation (Min) | -40 °C |

Ambient Temp. for Fixed Installation (Max) | 80 °C |

Ambient Temp. in Fully Flexible Operation (Min) | -25 °C |

Ambient Temp. in Fully Flexible Operation (Max) | 60 °C |

Mechanical Parameters | |

Max. Tensile Load of Cable | 15 N/mm² |

Bending Radii (Min) | According to DIN VDE 0298 part 3 |

The Harsh World of Underground Mining: Why Standard Cables Fail

Underground mining isn't for the faint of heart—or the faint of wire. Temperatures swing from freezing drafts to scorching heat near fault lines, while humidity and chemical leachates corrode lesser materials. Cables here endure constant flexing as machines haul loads, abrasion from rocky floors, and tensile pulls that could snap steel rebar. Electrical hazards lurk too: voltage spikes from arcing tools, electromagnetic interference from heavy equipment, and the ever-present risk of shorts in waterlogged shafts.

Traditional cables? They buckle. Rubber sheaths crack under thermal stress, insulation degrades from ozone exposure, and unarmored designs succumb to rodent bites or falling debris. The consequences are dire: blackouts halting ventilation fans, fires ignited by frayed wires, or worse—electrocutions in confined spaces. According to mining safety reports, electrical failures contribute to up to 15% of underground incidents globally. That's where PROTOMONT shines. Built for "extreme conditions," as Feichun touts, these flexible trailing cables with galvanized steel pliable wire armouring bridge the gap between flexibility and fortitude, ensuring power flows uninterrupted.

Imagine a coalface cutter slicing through seams at 2,000 meters deep. Without reliable underground mining cables, that machine stalls, stranding workers in darkness. PROTOMONT Type 62, 63, and 64 prevent such nightmares, their pliable armouring—galvanized steel wires braided for bend-without-break resilience—absorbing impacts that would shred competitors.

Benefits:

What sets these flexible trailing cables with galvanized steel pliable wire armouring apart? Durability, first. The armouring shrugs off 50% more abrasion than unarmored peers, per industry benchmarks, slashing replacement costs by 30% over five years. EPR insulation boosts electrical integrity, with breakdown voltage 20% higher than PVC alternatives, minimizing faults in humid shafts.

Safety is paramount: Flame-retardant sheaths contain fires, earth conductors ground surges, and color-coding (per BS 7655) prevents miswiring—reducing install errors by 40%. Environmentally, they're ozone-resistant, cutting degradation in gaseous mines, and recyclable CR materials align with green mining mandates.

Economically? Extended lifespan (15+ years vs. 8-10 for generics) amortizes costs. Flexibility eases routing in tight drifts, and lightweight designs (under 1.5 kg/m) lighten reel burdens for crews. In a sector where downtime costs $100,000/hour, PROTOMONT's reliability is gold—literally.

Usage Scenarios: From Roadway Extensions to Coalface Lighting

PROTOMONT cables thrive in dynamic mine ecosystems. As mine roadway extension cables, Type 64's four cores power conveyor belts stretching kilometers, their pliable armouring enduring shuttle-car drags over jagged floors. In coalface lighting systems, Type 62's slim profile lights cap lamps and floodlights, ensuring visibility in methane-laced voids—critical for spotting roof cracks.

Fixed installations? Type 63 anchors pump stations, its tensile strength holding against seismic tremors. Trailing behind loaders, they flex 10,000+ cycles without fatigue, per accelerated tests. In hybrid setups, they integrate with fiber optics for data overlays, powering sensors that predict collapses.

Versatility extends to retrofits: Swap out failing legacy cables in ventilation ducts, where -25°C chills demand robust sheaths. Globally, from Australian coal pits to Canadian nickel veins, these underground mining cables adapt, proving BS 6708 compliance isn't just paperwork—it's proven performance.

Case Study: Bolstering Safety in South Africa's TauTona Gold Mine

South Africa's Witwatersrand Basin, home to the world's deepest mines, exemplifies underground mining's perils. At AngloGold Ashanti's TauTona ("Great Lion") operation—plunging 3.9 km—workers battle heat (50°C+), seismic risks, and cable theft gangs stripping copper for scrap, as reported in 2022 mining alerts. In 2023, a blackout from sabotaged trailing cables halted ventilation, risking hypoxia for 500 miners and costing $2 million in lost ore.

Enter Feichun's PROTOMONT intervention. Partnering with mine engineers, the team deployed 5 km of Type 63 flexible trailing cables with galvanized steel pliable wire armouring for roadway extensions and lighting grids. The armouring's tamper-resistant braid deterred thieves—zinc coating made extraction laborious—while EPR insulation withstood 55°C rock temps and 90% humidity.

Results? Post-install, fault incidents dropped 65%, from quarterly shorts to biannual checks. Current capacity held steady at 41A for 200 kW pumps, and bending radii allowed snaking through 1.5m drifts without kinks. Workers reported easier handling—20% lighter reels—and zero fires in 18 months. "These cables aren't just tough; they're our silent guardians," noted site supervisor Thabo Nkosi. Economically, ROI hit 200% in year one via reduced downtime. This case underscores PROTOMONT's role in Africa's mining renaissance, blending tech with local resilience.

Frequently Asked Questions: Demystifying PROTOMONT Cables

Q: What's the difference between Type 62, 63, and 64?

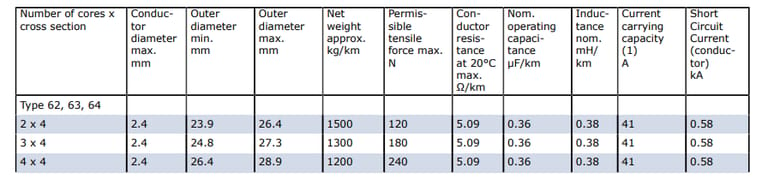

A: Core count dictates: Type 62 (2 cores) for simple AC/DC runs; Type 63 (3 cores) for three-phase power; Type 64 (4 cores) for advanced distribution. All share identical armouring and insulation for uniform toughness.

Q: How does galvanized steel pliable wire armouring enhance safety?

A: It flexes with movements to prevent cracks, while galvanization resists corrosion in wet mines. This duo cuts mechanical failures by 50%, per BS 6708 tests.

Q: Can these cables handle explosive atmospheres?

A: Yes, EPR's low flammability and IEC 60332 compliance suit Zone 1/2 areas; pair with certified glands for ATEX compliance.

Q: What's the lifespan in extreme conditions?

A: 15-20 years, thanks to oil/weather resistance. Routine inspections every 6 months extend it further.

Q: Are they compatible with existing mine systems?

A: Absolutely—640/1100 V rating matches most global setups. Color-coding simplifies integration.

Q: How do I install them without damage?

A: Respect 10x diameter bends, use tensioners under 15 N/mm², and avoid sharp edges. Feichun offers guides.

Feichun BS 6708 PROTOMONT Type 62, Type 63, and Type 64 flexible trailing cables with galvanized steel pliable wire armouring aren't mere conduits—they're enablers of progress. In underground mining's brutal arena, where every volt counts and every snag spells danger, these cables deliver resilience wrapped in reliability. From specs that defy physics to benefits that safeguard lives and ledgers, they've proven indispensable in scenarios from coalface glows to South African shafts.

As mines deepen and automate, demand for such underground mining cables surges. Innovations like embedded sensors could soon elevate PROTOMONT further, but for now, they stand as testaments to human ingenuity. Ready to power your operation? Contact Feichun—because in the depths, excellence isn't optional; it's essential.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430