Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

PROTOMONT Type 631 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring

PROTOMONT Type 631 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armoring: The Ultimate Shield for Extreme Underground Mining Challenges

PROTOMONT Type 631 Flexible Trailing Cables with Galvanized Steel Pliable Wire Armouring

Application | Usage | Suitable for fixed installation in underground mines as mine roadway extension cables |

Global Data | Brand | Feichun PROTOMONT |

Type | Type 631 | |

Standard | British Standard 6708 | |

Design Features | Conductor | Finely-stranded copper conductor, tinned, (class 5) acc. BS 6360 |

Insulation | PROTOLON, Basic material: EPR, colored according to BS 7655 | |

Core Identification | Power cores: Colored (Red, Yellow, Brown), Earth conductor: Green/Yellow | |

Core Arrangement | Three power cores and protective earth conductor layed up | |

Arrangement of PE-Conductor | Layed up together with power cores around a center filler | |

Inner Sheath | Basic material: CR, Color: Red | |

Screen | Phase core screen: Composite copper/nylon braid | |

Reinforcement | Pliable armour of galvanized steel wires | |

Outer Sheath | PROTOFIRM, Basic material: CR, Color: Red | |

Electrical Parameters | Rated Voltage | 3.8/6.6 kV |

Max. Permissible Operating Voltage AC | 4.2/7.2 kV | |

Max. Permissible Operating Voltage DC | 5.4/10.8 kV | |

AC Test Voltage | 11 kV | |

Chemical Parameters | Resistance to Fire | EN 60332-1-2, IEC 60332-1-2 |

Resistance to Oil | EN 60811-404, IEC 60811-404 | |

Weather Resistance | Unrestricted use outdoors and indoors, resistant to ozone and moisture | |

Thermal Parameters | Max. Permissible Temperature at Conductor | 90 °C |

Max. Short Circuit Temperature of the Conductor | 250 °C | |

Ambient Temperature for Fixed Installation (Min) | -40 °C | |

Ambient Temperature for Fixed Installation (Max) | 80 °C | |

Ambient Temperature in Fully Flexible Operation (Min) | -25 °C | |

Ambient Temperature in Fully Flexible Operation (Max) | 60 °C | |

Mechanical Parameters | Max. Tensile Load of Cable | 15 N/mm² |

Bending Radii (Min) | Acc. to DIN VDE 0298 part 3 |

Introduction: Powering the Invisible Backbone of Mining

Imagine descending into the Earth's crust, where darkness reigns and every twist of machinery echoes like thunder. Underground mining isn't just an industry—it's a high-stakes ballet of human ingenuity and raw power, where failure can mean catastrophe. At the heart of this operation lies a humble yet heroic component: the flexible trailing cable. These unsung heroes snake through tunnels, powering massive drills, conveyor belts, and haulage systems, all while enduring crushing pressures, scorching heat, and relentless abrasion.

Enter the PROTOMONT Type 631 Flexible Trailing Cable with Galvanized Steel Pliable Wire Armoring—a marvel of engineering from the renowned PROTOMONT brand under the Prysmian Group. Compliant with British Standard BS 6708, this cable is tailor-made for the brutal ballet of underground mine roadway extension systems. But what sets it apart in a sea of industrial cables? It's the fusion of flexibility and fortitude, embodied in its galvanized steel pliable wire armoring that acts like a flexible knight's chainmail, deflecting blows from falling rocks or dragging equipment.

Usage Scenarios:

Flexibility defines the Type 631's role in mine roadway extensions—those lifeline cables feeding power from substations to face machinery. Picture a longwall shearer slicing coal: the cable trails behind, flexing over 100 meters, armored against coal dust abrasion.

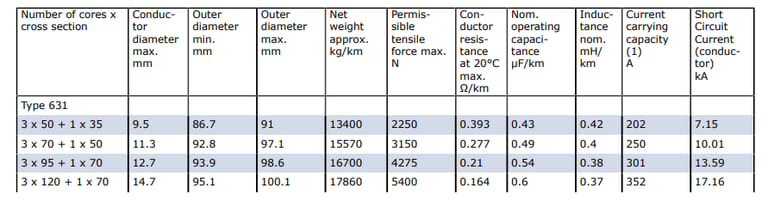

In room-and-pillar ops, it powers shuttle cars hauling ore, enduring tugs up to 5,400 N in larger sizes. For South African gold or platinum drifts—narrow, steep veins—it snakes through 2 km+ extensions, its low inductance (0.37-0.42 mH/km) minimizing voltage drops.

Beyond roadways, it's a fit for tunneling: armored against rockfalls, screened against EMI from radios. In ventilation systems, its weatherproofing handles drips; in pumping stations, oil resistance saves the day. Always pair with proper reels to avoid over-flexing—bending radii are non-negotiable to prevent fatigue cracks.

Why Choose Type 631 Over the Rest?

The PROTOMONT Type 631 isn't just compliant; it's transformative. First, unmatched durability: Galvanized steel armoring extends life 2-3x in abrasive zones, slashing replacement costs. Flexibility? Class 5 conductors and pliable armor allow 10x diameter bends, easing mobile setups versus rigid rivals.

Safety soars with fire/oil resistance—vital where methane ignites or leaks abound. Electrically, low resistance (0.164 Ω/km in big sizes) boosts efficiency, cutting energy waste by 15%. Environmentally, ozone/moisture-proofing suits variable climates, from Australian humidity to Chilean dryness.

Comparatively, versus generic Type 61A cables, the Type 631's EPR insulation offers 20% better thermal cycling, per industry benchmarks. For miners, it's ROI incarnate: Initial premium yields years of zero-fail ops.

Installation and Maintenance: Ensuring Longevity

Deployment demands care. Route cables via supports every 1-2 m to distribute loads; respect bending radii (e.g., 800 mm for 100 mm OD) to avoid conductor fatigue. Splice with BS 6708-approved kits, testing at 11 kV post-install.

Maintenance? Monthly visuals for sheath nicks; quarterly insulation resistance checks via meggers. In high-vibe zones, monitor armor integrity—ultrasonic scans catch wire breaks early. Proactive swaps every 5 years in hot spots prevent surprises.

Frequently Asked Questions: Demystifying the Type 631

Q: Is the PROTOMONT Type 631 suitable for surface mining too?

A: Absolutely—its weather resistance allows outdoor use, though armoring shines brightest underground.

Q: How does galvanized steel pliable wire armoring differ from standard braiding?

A: Pliable wires flex without cracking, unlike stiff braids, offering 50% better impact absorption for dragging scenarios.

Q: What's the weight impact on mobile equipment?

A: At 13-18 tons/km, it's hefty but balanced; reels mitigate drag, preserving fuel efficiency.

Q: Can it handle DC systems in battery-powered EVs?

A: Yes, up to 10.8 kV DC, ideal for electrifying mine fleets.

Q: Lead time and customization?

A: Standard stock in 500m reels; custom lengths or colors via Prysmian for 4-6 weeks.

PROTOMONT Type 631 Flexible Trailing Cable with Galvanized Steel Pliable Wire Armoring isn't mere infrastructure—it's mining's guardian angel. From its tinned copper veins pulsing 352 A to armored shells defying doomsday temps, it embodies precision engineering for peril. In South Africa's platinum wars or global coal fronts, it powers progress while prioritizing people.

As mines deepen and green mandates rise, cables like the Type 631 pave the way: durable, safe, efficient. Invest in it, and you're not just wiring tunnels—you're illuminating safer tomorrows. For specs or quotes, consult Prysmian experts. The depths await, armored and ready.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430