Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Pump Cable 300m

How Tough Rubber Submersible Pump Cables Conquer 300m Underwater Challenges in Industrial Power Solutions

Pump Cable 300m

Application | Tough rubber unscreened 0.6/1kV flat cable for installation inside or outside in dry, damp, or wet environments and hazardous environments (subject to local regulations). Can be immersed in fresh and salt water to a depth of 300 meters. Suitable for flexible power supplies, submersible motors, and pumps. Synthetic rubber compound is ozone, UV, sunlight, and weather resistant. |

Voltage Rating Uo/U | 0.6/1kV |

Test Voltage | 4kV |

Maximum AC Voltage | 0.7/1.2kV, 1.8kV DC |

Temperature Rating | Fixed: -40ºC to 90ºC Flexed: -25ºC to +90ºC |

Maximum Short Circuit Temperature | 250ºC |

Minimum Bending Radius | Height < 12 mm: 3 x H Height > 12 mm: 4 x H |

Conductor | Class 5 Tinned Copper |

Insulation | EPR (Ethylene Propylene Rubber) Compound - 3GI3 Quality |

Sheath | Water Resistant Rubber Compound - EM2 Quality |

Core Identification | 3 core: Green/Yellow, Blue, Brown 4 core: Green/Yellow, Brown, Black, Grey |

Sheath Colour | Black |

Standards | VDE 0207 Part 20, EN 50363-2-1, EN 60228 |

Flame Retardant | According to IEC 60332-1-2 |

Ozone Resistant | According to IEC 60811-403 |

Water Resistance Test | According to EN 50525-2-21 (AD8 condition) and AC internal test |

UV Resistant | According to ISO 4892-2 |

Introduction:

In the shadowy realms beneath our oceans, rivers, and even deep boreholes, where pressure crushes and water corrodes, lies a silent hero of modern engineering: the submersible pump cable. These aren't your everyday extension cords; they're robust, flexible lifelines designed to deliver uninterrupted electrical power to pumps and motors submerged up to 300 meters deep. Imagine a cable that withstands the relentless grip of saltwater, the bite of ozone, and the glare of UV rays—all while powering vital operations in mining, agriculture, and water management.

At the heart of this technology is the tough rubber unscreened 0.6/1kV flat cable, a product engineered for immersion in fresh and salt water environments. With a voltage rating of 0.6/1kV and the ability to handle test voltages up to 4kV, these cables are built for the extremes. But what makes them tick? In this article, we'll dive deep—pun intended—into the technical specifications, unravel their advantages, explore real-world usage scenarios, and even spotlight a case study from South Africa's rugged landscapes. By the end, you'll appreciate why these cables are indispensable for industries battling the elements. Whether you're an engineer tweaking designs or a curious reader fascinated by tech that tames the tides, buckle up for an insightful journey into cable technology.

Why Choose Tough Rubber for Submersible Depths?

In a world of flimsy wires, the 300m submersible pump cable stands tall—literally, in flat form—for its unmatched resilience. First, flexibility reigns supreme. Class 5 stranding allows coiling like a serpent, ideal for dynamic pump movements. Tinned copper repels corrosion, extending lifespan in brackish waters where untreated metals rust away in months.

EPR insulation is a game-changer. Unlike PVC, which cracks under ozone or UV assault, EPR maintains integrity from -40°C Arctic chills to 90°C tropical steams. Its low permittivity reduces capacitive losses, preserving power over long runs. The EM2 sheath? A fortress against water ingress, blocking hydrolysis and microbial growth that plague lesser cables.

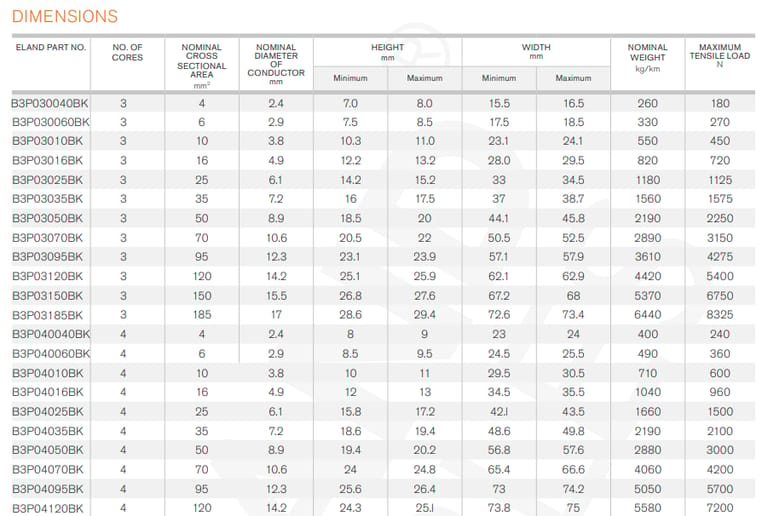

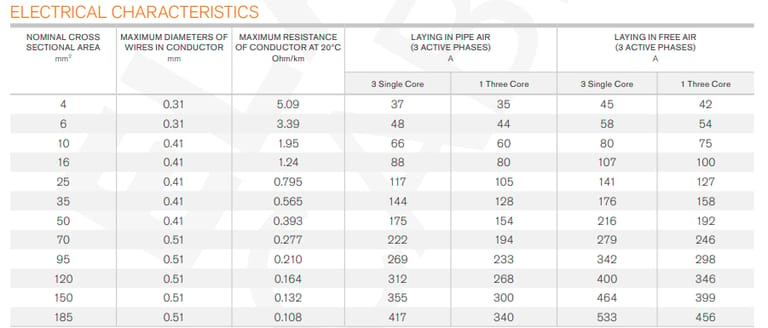

Safety is woven in: flame-retardant to IEC 60332-1-2, it self-extinguishes, curbing fire spread in confined shafts. Ozone and weather resistance mean no brittle sheathing after sun exposure—vital for outdoor reeling. Economically, flat design cuts installation costs; less material, easier handling. Tensile strength up to 8325 N supports vertical drops without sagging, and low resistance ensures efficient ampacity—up to 533A in free air for larger cores—slashing energy waste.

Environmentally, these cables shine. Synthetic rubber compounds are free of halogens, reducing toxic smoke in faults. Recyclable copper cores promote circular economies. In hazardous zones, compliance with local regs allows deployment where others dare not. Versus alternatives like armored cables, they're lighter (260-6440 kg/km) and cheaper, without sacrificing 300m submersion prowess. It's not hype; it's engineering that turns underwater power from gamble to guarantee.

Usage Scenarios:

Submersible pump cables aren't niche; they're workhorses across sectors. In agriculture, picture vast South African farmlands: deep boreholes tap aquifers for irrigation. A three-core 25 mm² cable powers a 141A pump, its flat profile snaking down 200m without tangling, EPR shielding against groundwater corrosives.

Mining amplifies the drama. Underground shafts flood fast; submersible pumps drain them. Four-core 70 mm² cables, with 4200 N tensile, haul 279A to dewater gold mines, EM2 sheath defying abrasive slurries. Oil and gas? Offshore platforms deploy these for sump pumps, 300m ratings handling tidal surges, UV resistance enduring deck exposures.

Wastewater treatment thrives on them too. Municipal plants submerge pumps in sewers; 50 mm² cables manage 216A loads, flame-retardancy a boon near methane pockets. Aquaculture farms in coastal bays use lighter 10 mm² variants for aerators, ozone-proofing against bubbly ozone treatments.

Even renewables: tidal energy converters rely on these for underwater turbines, flex rating (-25°C to 90°C) coping with current-induced whips. Installation? Reel out via winches, minimum bend radius ensuring no fatigue. In air-pipe lays, derate for heat; free air boosts capacity. Versatile? Absolutely—dry warehouses to damp vaults, always ready for the plunge.

Frequently Asked Questions:

Q: How deep can these cables really go?

A: Rated for 300m immersion in fresh or salt water, thanks to water-resistant EM2 sheathing and pressure-tested construction per EN 50525-2-21.

Q: What's the difference between three-core and four-core?

A: Three-core suits single-phase or delta three-phase loads (e.g., motors); four-core adds a neutral for wye configs, ideal for balanced industrial pumps.

Q: Can they handle extreme temperatures?

A: Absolutely—fixed installs from -40°C to 90°C, flexed -25°C to 90°C, with 250°C short-circuit tolerance via EPR's thermal stability.

Q: Are they safe in hazardous areas?

A: Yes, flame-retardant (IEC 60332-1-2) and ozone-resistant, compliant for damp/wet zones, but check local regs for explosivity.

Q: How do I select the right size?

A: Match cross-section to ampacity—e.g., 16 mm² for 88A in pipes—and depth/load. Use tables for resistance/weight to avoid drops.

Q: Maintenance tips?

A: Inspect for sheath cracks annually; reel slowly to respect bend radius. Tinned ends prevent oxidation.

Q: Eco-friendly?

A: Halogen-free, recyclable copper—yes, minimizing environmental impact in sensitive deployments.

From the specs etched in copper to the sheaths battling the deep, the 300m submersible pump cable embodies human ingenuity against nature's odds. Its tough rubber build, EPR heart, and standards-backed reliability make it a cornerstone for sustainable power underwater. As South Africa's mines show, it's more than wire—it's progress plunged into action. Next time you sip water from a deep well or admire a flood-free mine, thank these unsung cables. The depths await, powered and unafraid.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430